AMADA PRESS SYSTEM

Automation System for Stamping Processing

NEW

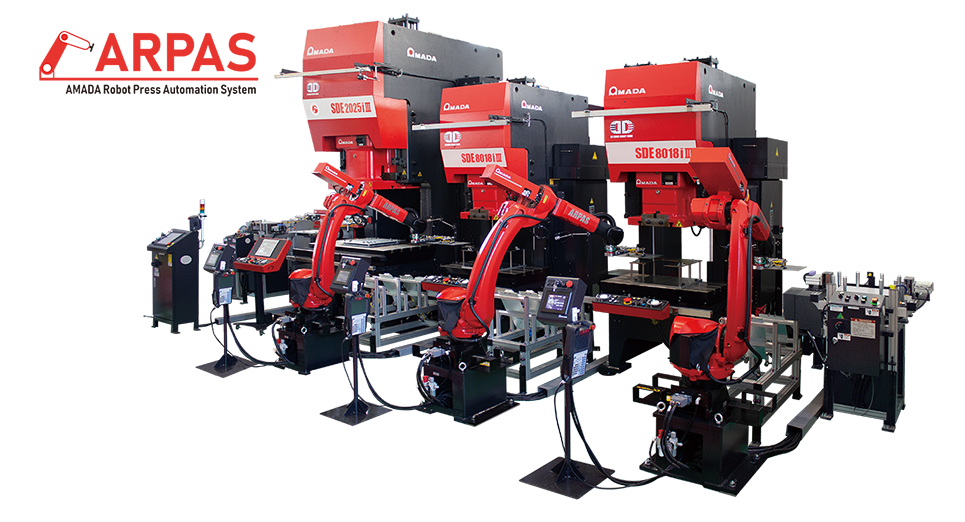

ARPAS Servo-Drive Stamping Presses (800 kN ~ ) + Articulated Robots

High-Speed Line System with Articulated Robots and Servo-Drive Stamping Presses

ARPAS

WAVE synchronized control operation helps the system to achieve high-speed workpiece transfer between stamping press machines.

Features

- 1. Improved productivity through WAVE synchronized control operation

- ARPAS, with the WAVE synchronized control operation, allows the workpiece to be transported while overlapping the operations of the stamping press machines and the transfer robots. This minimizes processing time, making it possible to improve production time.

- 2. Improved operability with a line controller

- ARPAS uses a line controller to collectively manage robots and stamping press machines’ operation information, which greatly improves operability.

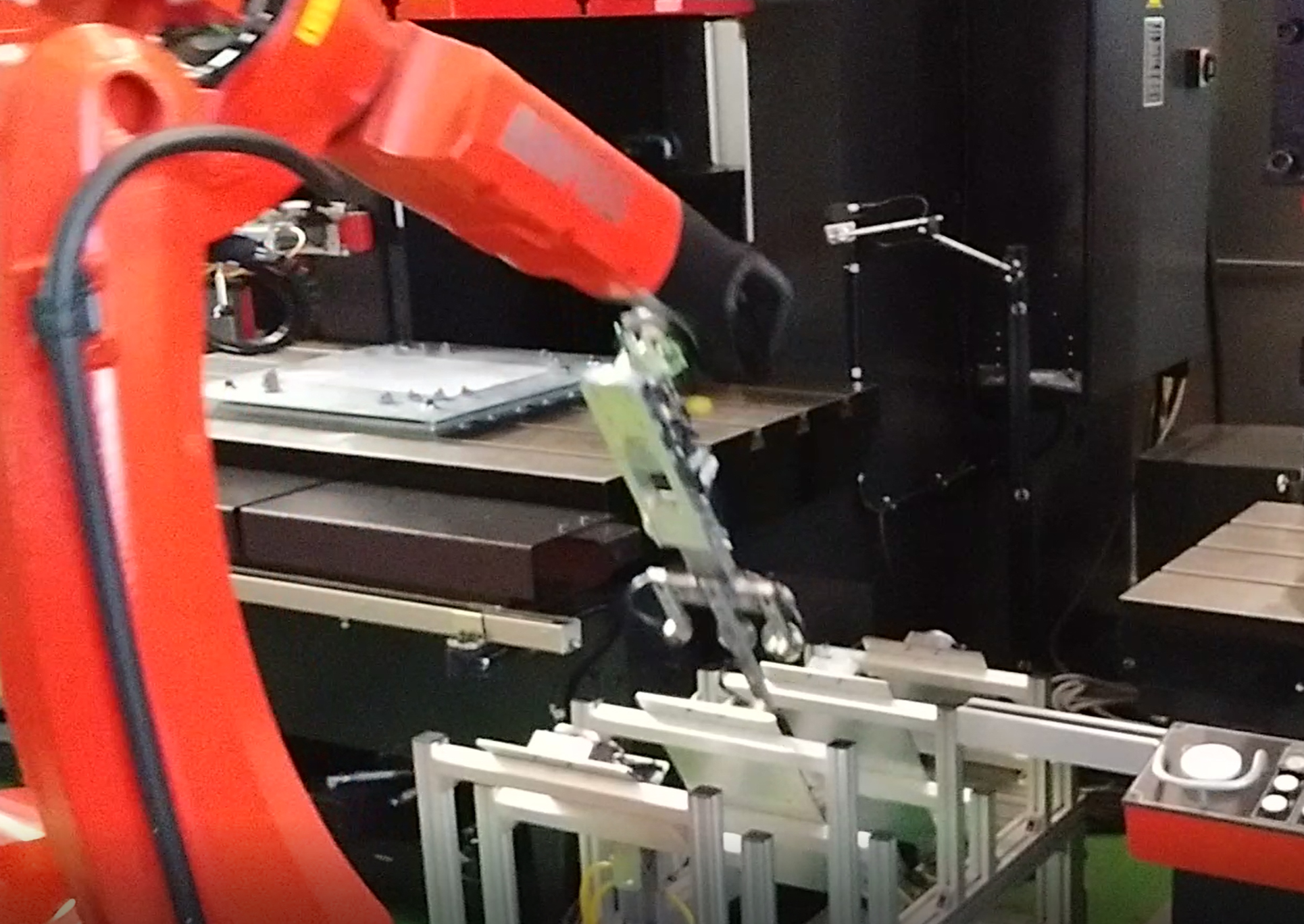

- 3. Labor saving with an automatic end of arm tooling changing system (optional)

- Changing of the end of arm tooling has been automated. This reduces setup time and labor. We offer a wide variety of unique end of arm tooling that meet customer needs and have been well received for many years.

-

Automated end of arm tooling change

- 4. Camera monitoring for operational support (optional)

- Cameras are installed to monitor the transport status and the processing line, allowing video to be recorded while processing. When an error or stop occurs, the operator can check the internal device information and the video from around the time the error occurred, allowing for early recovery.

-

Screen of Camera monitoring

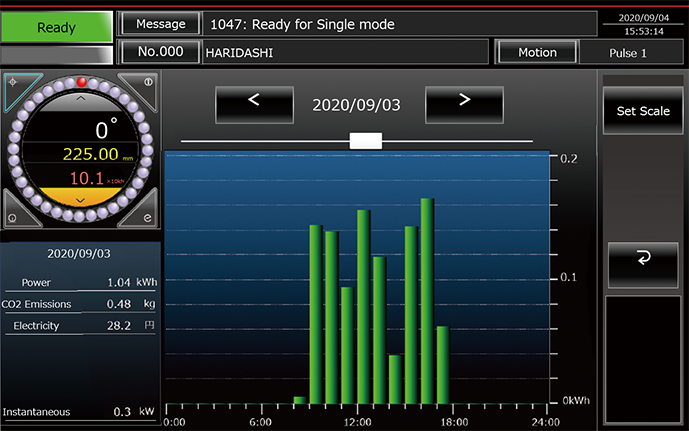

- 5. ECO-friendly servo press machines with environmental consideration

- Our stamping servo press machines are ECO machines, or environmentally conscious products, which contribute to environmental impact reduction and working environment improvement.

- Power conservation: Sharp reduction of power consumption*

- Resource conservation: Reduction of lubricating oil consumption*

- Working environment: Significant reduction of stamping noise*

* Mechanial stamping press machine of the same class

Movies

Introduction: ARPAS, High-Speed Tandem Line System with Articulated Robots and Servo-Drive Stamping Presses

Processing comparison: ARPAS, High-Speed Tandem Line System with Articulated Robots and Servo-Drive Stamping Presses

Specifications

| Machine name | Details | |

|---|---|---|

| ARPAS | Applicable presses | "i3" control-mounted stamping servo press with C-type frames |

| Applicable robots | 2-axis servo robots (top), 6-axis articulated robots |

|

| Workpiece holding method | Vacuum, electromagnet | |

| Maximum carrying mass | 2 kg | |

| Maximum number of connections servo press/robot |

8 / 8 | |

Related products

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for overseas specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us