AMADA PRESS SYSTEM

Spring Machines

Torsion Spring Machines

NEW

TM-8A (ø0.2 ~ ø0.8 mm)

11-Axis CNC Torsion Spring Machine with Rotating Tool Table

Precision processing with a tool table rotation mechanism that is optimal for fine wire.

Equipped with the latest spring forming program MNO2, the TM-8A has evolved into the ultimate torsion forming machine for fine wire.

Features

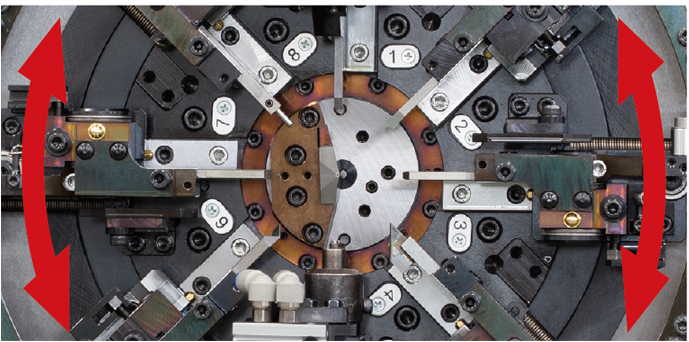

- 1. Improved processing quality with rotating tooling table mechanism

-

- The tool table, equipped with eight slides, rotates at high speeds around the quill. The slides can be set to any angle of 360° to the wire, making it easy to set and adjust the shape.

- Equipped with 11 standard axes for feed, table rotation, 8 slides, and quill rotation.

- Slides are also equipped with an automatic correction function that prevents the slide from moving back and forth when the tool table is rotated at the forming position.

- Switching to a square quill allows for processing products with long twirls.

- 2. Improved operability with the MNO2 (MEC New Operation 2) programming software

-

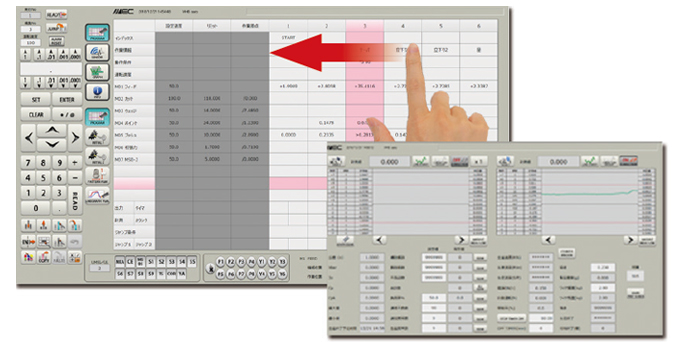

- The MEC original spring program MNO2 easily organizes important statistics about the machine, including program flow, operating status of each axis, inputs/outputs, jump, etc., as with our other spring machines.

- The program editing function has greatly evolved, and the navigation system function and touch screen make it easier to create programs and shorten the setup time.

- The servo motor control enables high resolution and precise operation.

- The motor sensor system makes every slide a sensor. It is possible to measure the presence/absence judgment with a touch sensor, coiling angle, free length, etc. in 0.001 mm units. The measurement results are displayed in tables and graphs, and easy correction control for each axis is possible.

- Highly efficient production is supported by a versatile production management and data collection functions.

- 3. Main options

-

- RR servo slide: spinner processing, max 3 pcs

- Servo body slide unit: servo powered diameter adjustment

- Reverse bending slide unit: allows bending toward the operator

- 10 mm raising unit: widens the twirling spaced

- Slip sensor: detects wire feed slip

- 4. Support for IOT

- The operating status of machine can be monitored through mobile phones or computers, and regular maintenance with preventive maintenance functions can contribute to improved production efficiency.

Movies

Specifications

| Machine name | TM-8A |

|---|---|

| Wire diameter | ø0.2 ~ ø0.8 mm |

| Max Twirl distance (Using square quill) | 36 mm |

| Index | D/d 4 or more |

| Body slide | 1 unit |

| Bending slide | 3 units |

| Cut slide | 4 units |

| RR servo slide | 3 units (Optional) |

| Max air pressure | 0.5 MPa |

| Power source | 3-phase, AC 200V, 15A |

| Net weight | 480 kg |

| Control device | Windows |

| Software | MNO2 |

| Display | 15.6” Full HD touch screen |

| External memory | USB Thumb drive |

| Temperature | 5 ~ 40°C |

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for non-Japanese specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us