ALFAS Servo-Drive Stamping Presses (800 - 1600 kN) + ALFAS-03ARZ High-Speed NC Roll Feeder Line

Automation System for Progressive Stamping Press Production

i3 Series + ALFAS-03ARZ

This system, which combines a high-rigidity stamping servo press with a double crank mechanism and a high-speed NC roll feeder and up-looped straightener, was developed for EV component processing. The high-speed and high precision feed of the roller feeder and the high-pendulum motion of the stamping servo press allow this system to achieve high-productivity and high-quality processing.

Features

- 1. Improvement of productivity and quality by high-speed and high-precision feed

- We developed a high-speed NC roll feeder that has about four times the top speed of our conventional model with an up-looped straightener. By incorporating a backlashless mechanism, which directly connects the servo motor and feed roll with a coupling, the speed and accuracy of the servo motor can be directly transmitted to the feed roll. High-speed, high-precision feed of roll feeder, and high-speed pendulum motion of the stamping servo press machine results in stable processing.

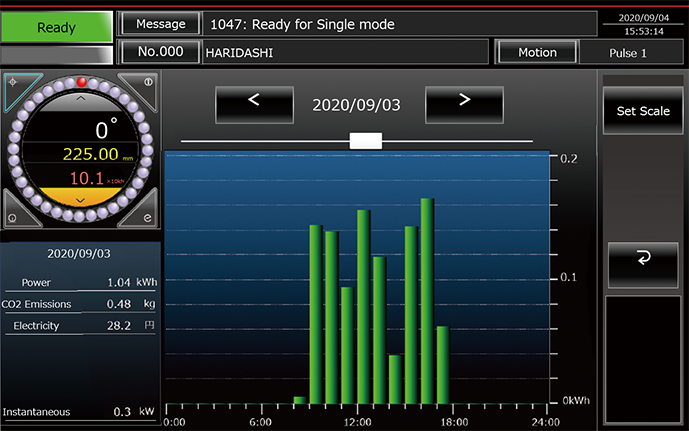

- 2. Improved operability through integrating operation screen and controls

- One control system unites the individual operation controls of the stamping press machine and the roll feeder, which has greatly improved operability.

- 3. Easy-to-use 3-mode operation screens for feeder

- In the pursuit of ease of use, we designed three basic screens for the feeder. With these, the operator can access and operate with all necessary information quickly and easily in each mode.

-

Setting

Setup

Operation

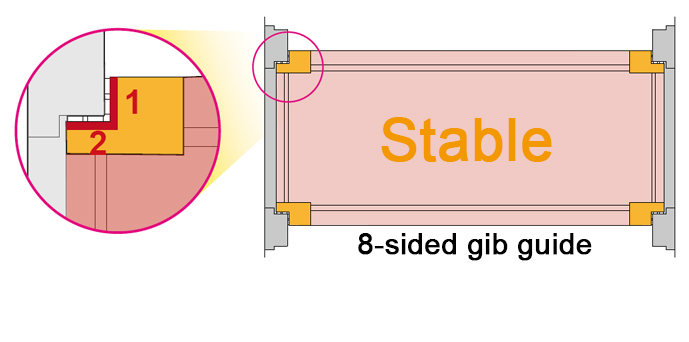

- 4. Double-crank mechanism with excellent eccentric load resistance and 8-sided gib guide structure

- For the first time in the GORIKI Series, a double-crank mechanism has been introduced. The 8-sided gib guide on the slide part improves eccentric load resistance and maintains stable processing accuracy during production. It is especially effective for forming asymmetrical parts that require high eccentric load resistance.

-

- 5. Space saving with an up-looped straightener

- We have successfully optimised and shortened the amount of loop between the uncoiler, straightener, and roll feeder with simple analog loop controls and up-loop type where the straightener is placed diagonally. This makes it possible to save about 40% of space compared to our down-looped roll feeder.

-

Achieves space saving of about 40%

- 6. ECO-friendly servo press machines with environmental consideration

- Our servo-drive stamping press machines are ECO machines, or environmentally conscious products, which contribute to environmental impact reduction and working environment improvement.

- Power conservation: Sharp reduction of power consumption*

- Resource conservation: Reduction of lubricating oil consumption*

- Working environment: Significant reduction of stamping noise*

* Mechanical stamping press machine of the same class

- 7. New environment-friendly servo release mechanism (patent pending)

- The release drive of the roll feeder upgraded from an air cylinder type to a servo release mechanism, which uses a cam. By integrating digital pressurization, which can adjust the pressure applied to the feed roll according to the material specifications, minimum release amount and optimum pressurization can be set. This reduces scratches on the material, noise and air consumption, and improves the durability of the roll feeder.

Movies

Automation System for Progressive Stamping Press Production SDEW-8010i3 + ALFAS-03ARZ

Automation System for Progressive Stamping Press Production SDEW-1613i3 + ALFAS-03ARZ

Specifications

System example 1

SDEW-8010i3 + ALFAS-03ARZ

| Machine name | Details | |

|---|---|---|

| Whole system | Dimensions (W x H x D) | 5938 x 2988 x 1920 mm |

| Stamping servo press machine SDEW-8010i3 |

Capacity | 800 kN |

| No. of strokes | ~ 130 min-1 | |

| Stroke length | 100 mm | |

| Die height | 320 mm | |

| High-speed NC roll feeder line ALFAS-03ARZ |

Stock width | 50 ~ 300 mm |

| Stock thickness | 0.2 ~ 1.0 mm | |

| Max coil mass | 2000 kg | |

| Max coil O.D. | ø1200 mm | |

| Coil I.D. | ø508 mm | |

| Max feed speed | 6.0 m/sec | |

System example 2

SDEW-1613i3 + ALFAS-03ARZ

| Machine name | Details | |

|---|---|---|

| Whole system | Dimensions (W x H x D) | 5500 x 3400 x 2225 mm |

| Stamping servo press machine SDEW-1613i3 |

Capacity | 1600 kN |

| No. of strokes | ~ 100 min-1 | |

| Stroke length | 130 mm | |

| Die height | 400 mm | |

| High-speed NC roll feeder line ALFAS-03ARZ |

Stock width | 50 ~ 300 mm |

| Stock thickness | 0.2 ~ 1.0 mm | |

| Max coil mass | 2000 kg | |

| Max coil O.D. | ø1200 mm | |

| Coil I.D. | ø508 mm | |

| Max feed speed | 6.0 m/sec | |

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for overseas specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us