AMADA PRESS SYSTEM

Automation System for Stamping Processing

NEW

ALFAS Servo-Drive Stamping Press (800 ~ 6000 kN) + ALFAS-03KR Straightener-Feeder

Automation System for Progressive Stamping Press Production

i3 Series + ALFAS-03KR

One control system unites the individual operation controls of the stamping press machine and the straightener-feeder, which has greatly improved operability.

Features

- 1. Improved operability through integrating operation screen and controls

- One control system unites the individual operation controls of the stamping press machine and the straightener-feeder, which has greatly improved operability.

- 2. Improved productivity with high-speed feed

- In addition to the conventional standard feed speed, a high-speed mode with a faster top speed has been newly installed. For materials with smaller stock width and thickness or yield strength, selecting the high-speed mode increases the top speed by approximately 40% to boost productivity.

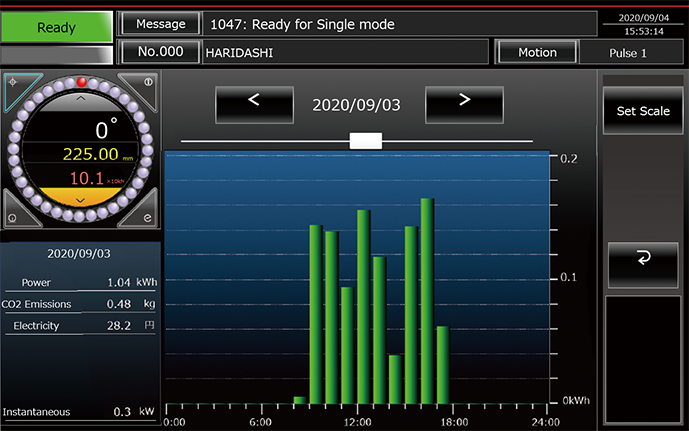

- 3. Easy-to-use 3-mode operation screens for feeder

- In the pursuit of ease of use, we designed three basic screens for the feeder. With these, the operator can access and operate with all necessary information quickly and easily in each mode.

-

Setting

Setup

Operation

- 4. Simplified setup operations with the feeder timing setting

- ALFAS can automatically detect the start/end positions of dies processing based on the load's waveform detected by the built-in load monitor at the time of test processing. This makes it possible to automatically set the timing of release, feed start and feed interference of the straightener-feeder by inputting the height of the pilot pin and the workpiece.

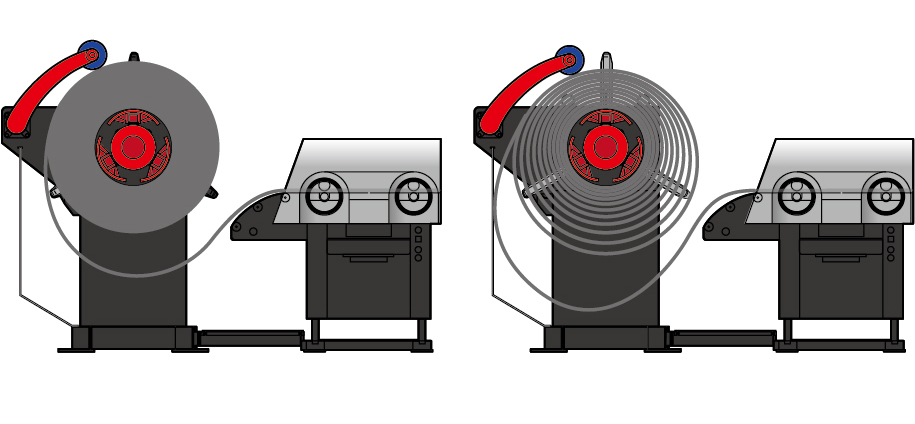

- 5. Simple analog loop control for improved quality and labor-saving

- Simple analog loop control enables uncoilers to continually rotate at a constant speed during auto operation, allowing stabilized behavior and preventing loosening. This reduces material scratches during loop formation, leading to better product quality.

-

Left: with analog loop control Right: without analog loop control

- 6. ECO-friendly servo press machines with environmental consideration

- Our stamping servo press machines are ECO machines, or environmentally conscious products, which contribute to environmental impact reduction and working environment improvement.

- Power conservation: Sharp reduction of power consumption*

- Resource conservation: Reduction of lubricating oil consumption*

- Working environment: Significant reduction of stamping noise*

* Mechanial stamping press machine of the same class

Movies

Automation System for Progressive Stamping Press Production SDE-1515i3 + ALFAS-03KR

Specifications

System Example

SDE-1515i3 + ALFAS-03KR

| Machine name | Details | |

|---|---|---|

| Whole system | Dimensions (W x H x D) | 5200 x 3400 x 2000 mm |

| Stamping servo press machine SDE-1515i3 |

Capacity | 1500 kN |

| No. of strokes | ~ 95 min-1 | |

| Stroke length | 150 mm | |

| Die height | 380 mm | |

| Straightener-feeder ALFAS-03KR |

Stock width | 50 ~ 300 mm |

| Stock thickness | 0.3 ~ 3.2 mm | |

| Max coil mass | ~ 2000 kg | |

| Max coil O.D. | ~ ø1200 mm | |

| Coil I.D. | ø508 mm | |

| Max feed length | ~ 400 mm | |

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for overseas specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us