TPW-FX Series 2-point / 1100 ~ 3000 kN

Double Crank Stamping Press Machines

Long-selling double crank presses to meet various customer needs

TPW-FX Series has adopted a wet clutch/brake unit that has a small energy loss and positively starts and brakes even during high-speed operation.

It also has a sealed oil bath transmission that can operate maintenance free over a long period of time.

TPW-FX stamping presses are enormously favored in all aspects, including systematization with a wealth of peripheral units and expandability and operability from single-hit stamping, progressive die and transfer line configurations.

Features

- 1. Flexibility

- Traditional AMADA wet transmission produces high torque and energy and ensures positive braking power transfer.

- 2. Functionality

- A TFT color touch screen is fitted as standard and provides better visibility and operability.

Eco-counter and eco-idling functions are equipped as standard.- Eco-counter function: When the production count reaches the preset count, the motor automatically enters the idle condition and draws less power.

- Eco-idling function: When its standby time reaches the preset time, the motor automatically enters the idle condition and consumes less power. - 3. Futurity

- Visualization of press operating conditions and maintenance information with touch screen PC The Ethernet is equipped as standard.

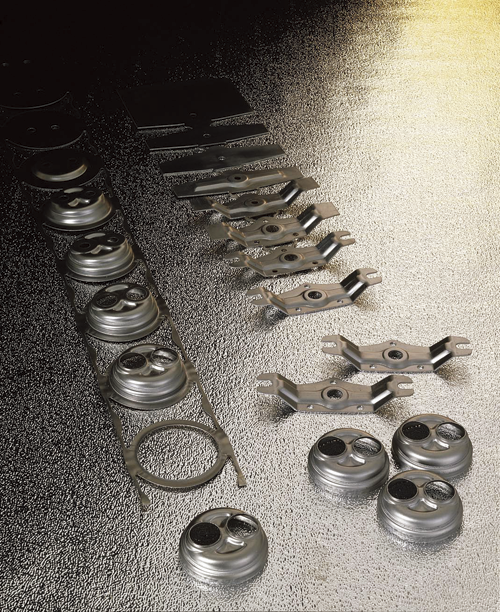

Production Samples

Specifications

| Machine name |

Frame |

Frame |

Frame |

Capacity |

Stroke length |

No. of strokes |

Die height |

|---|---|---|---|---|---|---|---|

|

TPW-110FX |

C | BI | - |

1100 |

180 / 110 / 230 |

35~65 / 55~110 / 25~50 |

400 / 350 / 450 |

|

TPW-150FX |

C | BI | - |

1500 |

200 / 130 / 250 |

30~55 / 45~90 / 25~45 |

450 / 400 / 500 |

|

TPW-200FX |

C | BI | BO |

2000 |

250 / 150 / 300 |

25~45 / 40~75 / 20~35 |

500 / 450 / 550 |

|

TPW-250FX |

C | BI | BO |

2500 |

250 / 170 / 300 |

20~40 / 30~60 / 15~30 |

550 / 450 / 600 |

BI type (Inner bridge wide): Adapted for multiple-step stamping and progressive-die stamping of thin sheets

BO type (Outer bridge): Adapted for multiple-step stamping and for use of larger thin sheet stamping dies

3000 kN: For special specifications

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for overseas specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us