AMADA PRESS SYSTEM

Stamping Presses

Digital AC Servo Press

NEW

SWE-i3 Series 2-point / 4000, 6000 kN

Digital AC Servo Press

In addition to the 4000 kN digital electric double crank servo press that has been well received since its release, we have added a 6000 kN type to our lineup.

The new “i3” control offers the ability to achieve high-precision forming and improved productivity.

Features

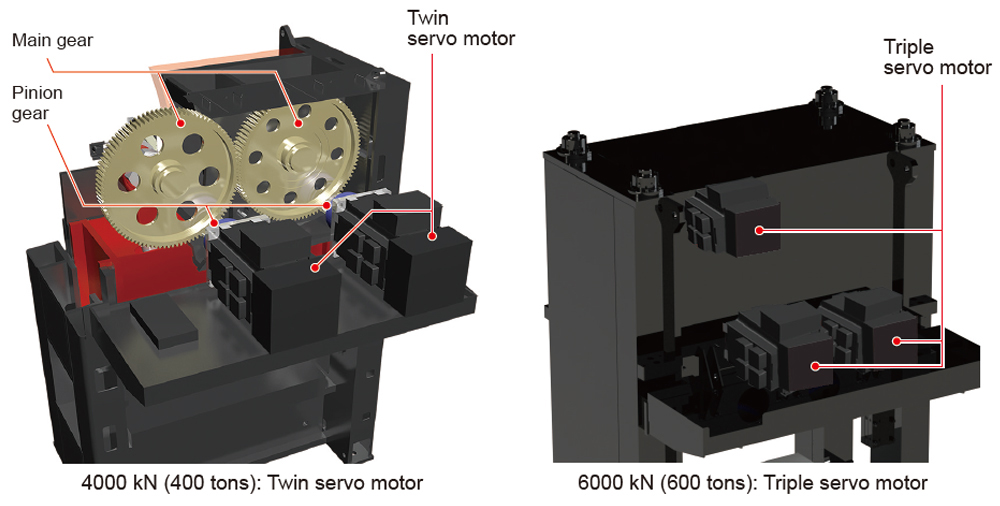

- 1. High-productivity, high-value-added forming with the latest drive mechanism

- Equipped with our own servo motor, we have improved the capacities of pressure, torque, and energy, and expanded the manufacturing range.

4000 kN: Twin servo motor

6000 kN: Triple servo motor -

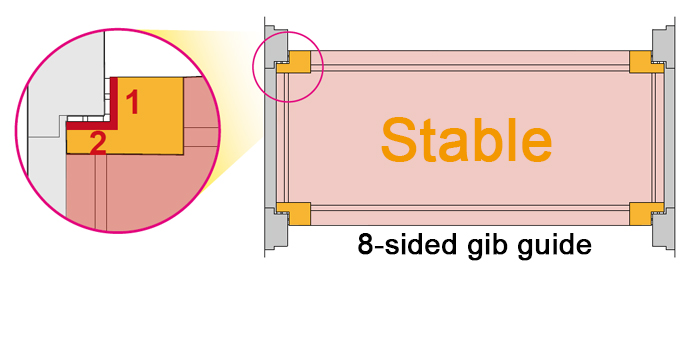

- 2. Optimum high-rigidity frame structures to meet the required accuracy

- A highly rigid straight-side integrated frame and an 8-sided gib guide system are used to maintain stable accuracy during production.

-

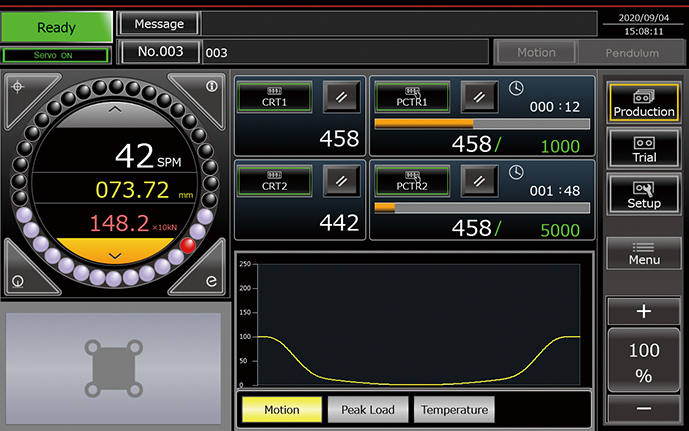

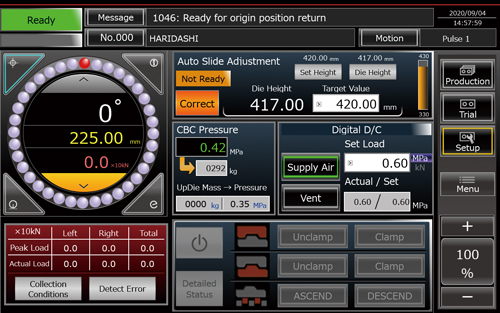

- 3. Improved operability of the screen

- Three types of basic operation mode screens are provided for ease of use. Verifying the necessary information in each operation mode can be done quickly and easily.

-

Production

Trial

Setup

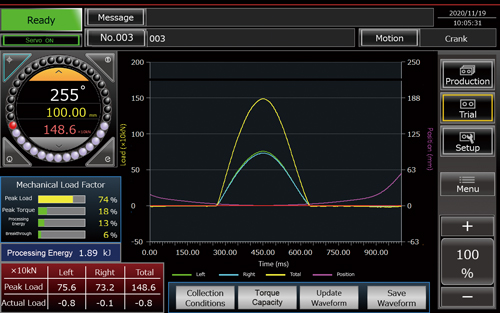

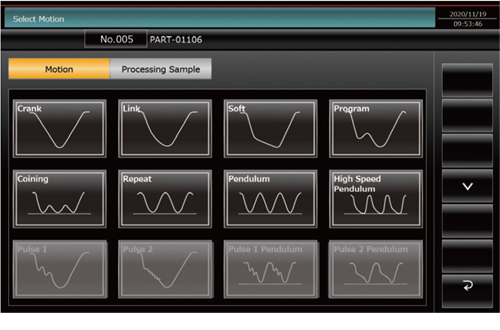

- 4. Diverse motion patterns

- By selecting the most optimal motion path according to the product, it is possible to improve formability, accuracy, and reduce cost.

-

Diverse motion patterns

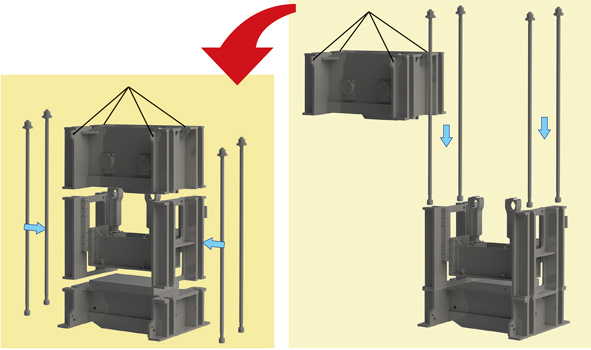

- 5. Simplification of shipping/transportation and installation

(SWE-6040i3 only) - A new three-part straight side frame structure has been implemented. As a result, we have developed a side insertion method for tie rods that reduces the permissible installation height at the factory by approximately 30%.

-

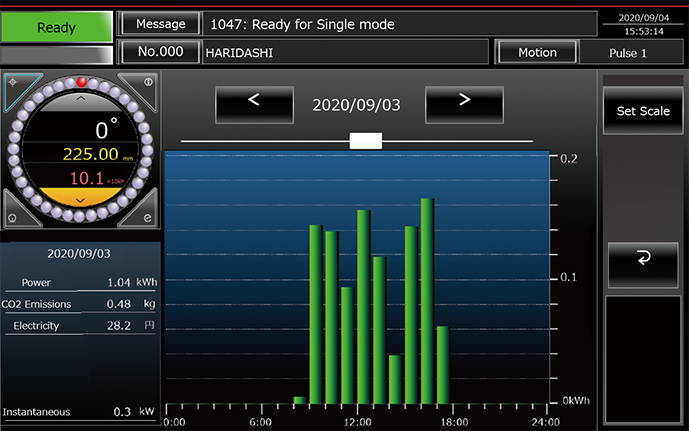

- 6. ECO-friendly servo press machines with environmental consideration

- AMADA’s servo press machines are ECO machines, or environmentally conscious products, which contribute to environmental impact reduction and working environment improvement.

- Power conservation: Sharp reduction of power consumption*

- Resource conservation: Reduction of lubricating oil consumption*

- Working environment: Significant reduction of stamping noise*

* Mechanial stamping press machine of the same class

Specifications

| Machine name | Capacity kN |

Stroke length mm |

No. of strokes min-1 |

Die height mm |

SWE-4025i3 SWE-4025i3 |

4000 | 250 | ~ 45 | 600 |

SWE-6040i3 SWE-6040i3 |

6000 | 400 | ~ 40 | 600 |

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for overseas specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us