SDE-i3 Series 1-point / 800 ~ 3000 kN

Digital AC Servo Press

Newly Released 3rd Generation Servo Press Machine Series i3

The newly developed "i3" control system offers the ability to achieve high-accuracy forming with improved productivity.

![]()

Features

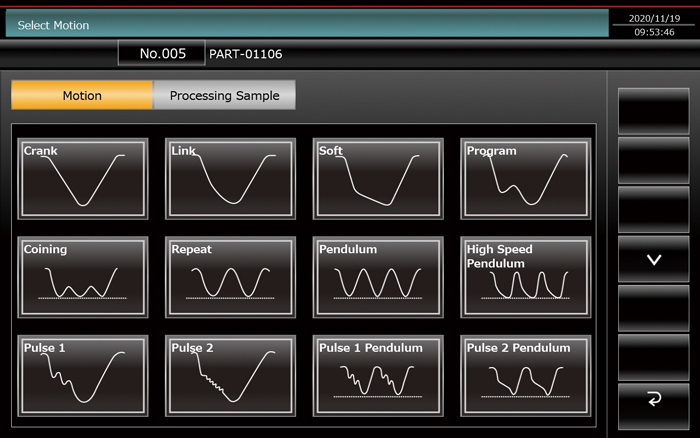

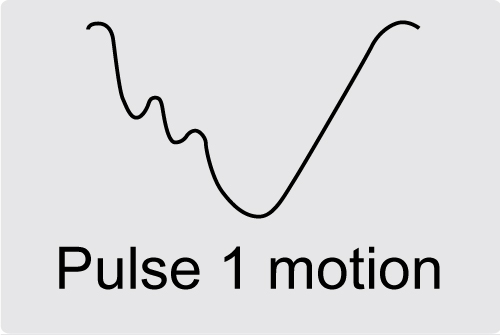

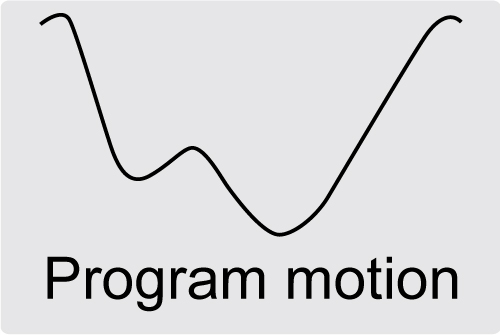

- 1. Twelve kinds of motions

- By selecting the most optimal motion path according to the product, it is possible to improve formability, accuracy, and reduce cost.

-

Sample motion screen

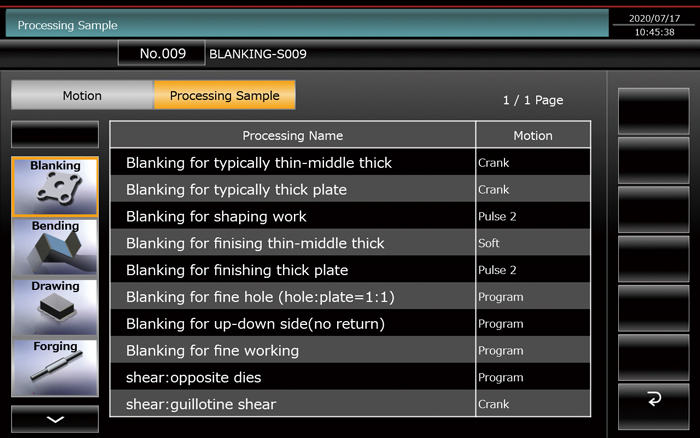

- 2. Simple Selectable Motion Programming (SSMP)

- The new standard process sample programming, along with motion sample programming and motion editing, makes the i3 control significantly more simple and easy to program, even for less experienced users.

-

Processing sample screen

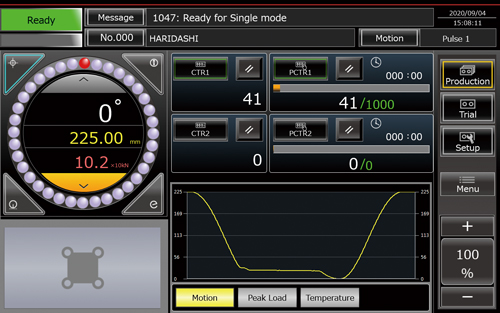

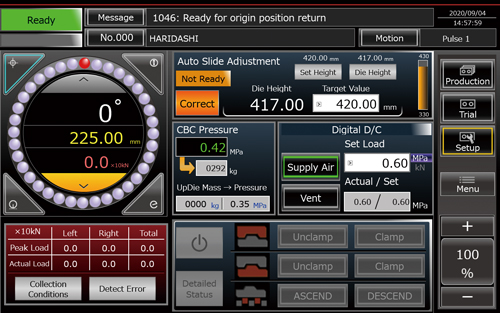

- 3. Improved operability of the screen

- Three types of basic operation mode screens are provided for ease of use. Verifying the necessary information in each operation mode can be done quickly and easily.

-

Production

Trial

Setup

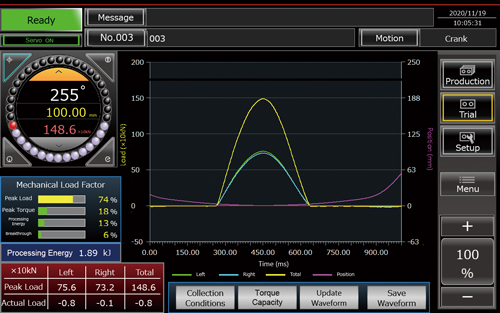

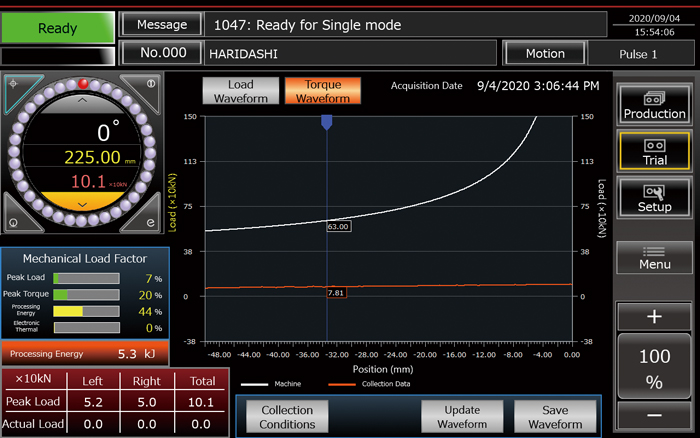

- 4. Built-in colour graph load/torque monitor as standard equipment

- Each i3 control is equipped with the enhanced load/torque monitoring system, which is more advanced than your normal tonnage monitor.

-

Curve diagram display of torque waveform

- 5. Automatic slide adjustment as standard equipment

- The automatic slide adjustment functions allows the operator to adjust the die height according to a previously programmed job memory setting. This reduces setup time and eliminates the chance of inputting the wrong setting.

-

Display of automatic slide adjustment

- 6. ECO-friendly servo press machines with environmental consideration

- AMADA’s servo press machines are ECO machines, or environmentally conscious products, which contribute to environmental impact reduction and working environment improvement.

- Power conservation: Sharp reduction of power consumption*

- Resource conservation: Reduction of lubricating oil consumption*

- Working environment: Significant reduction of stamping noise*

* Mechanial stamping press machine of the same class

Movies

SDE-i3 & SDEW-i3 Series Introduction

Material: Brass, Thickness: 2.0 mm

Production Samples

Construction method conversion and high-precision processing

Machine: SDE-2025i3 (SF)

Material: Low carbon steel (JIS: S10C)

Size:

Before processing: ø17.6 x ø9.2 x 25.8 mm

After processing: ø23.2 x ø7.0 x 17.0 mm

Helical gear

Improved forming quality and high-quality processing

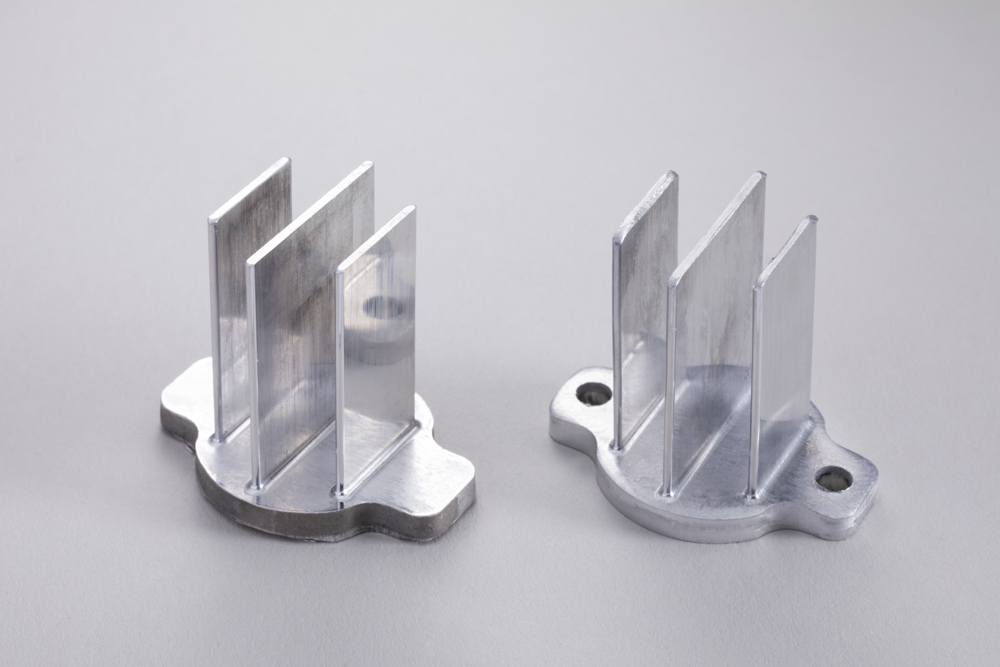

Machine: SDE-3030 (SF)

Material: Aluminium (JIS: A1100)

Thickness: 8.0 mm

Size (W x H): 1.2 x 32.6 mm

Part of heat sink

Systemup Examples

Customers can upgrade their systems by selecting and combining the optimal peripheral equipment and other components.

Robot Line System / Press-to-press transfer

Robot series support the automation of press processing with sophisticated designs and a wide range of types and variations.

Click here for details on workpiece transfer robots

Coil handling system

The best combination with straightener-feeder “LCC Series.” A variety of lineups according to the processing content and high operability are realized, contributing to high-precision processing.

Click here for details on coil material supply

SDE-8018i3 + RHQ120

Specifications

| Machine name | Frame C type |

Rigidity frame SF type |

Capacity kN |

Stroke length mm |

No. of strokes min-1 |

Die height mm |

| SDE-8018 i3 | C | SF | 800 | 180 | ~ 80 | 350 |

| SDE-1120 i3 | C | SF | 1100 | 200 | ~ 70 | 390 |

| SDE-1522 i3 | C | SF | 1500 | 225 | ~ 60 | 430 |

| SDE-2025 i3 | C | SF | 2000 | 250 | ~ 55 | 460 |

| SDE-3030 i3 | - | SF | 3000 | 300 | ~ 40 | 550 |

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for overseas specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us