AMADA PRESS SYSTEM

Spring Machines

Torsion Spring Machines

NEW

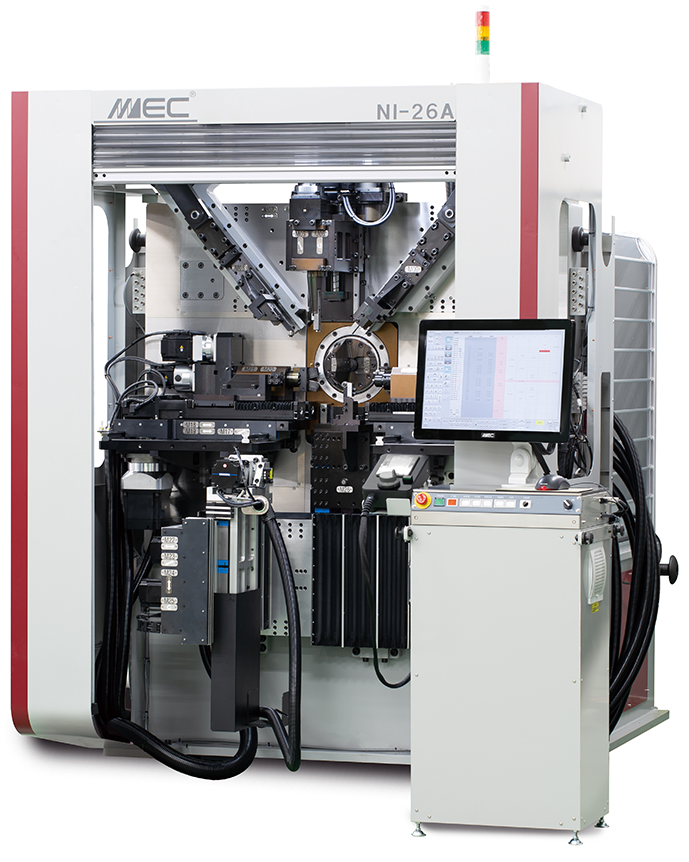

NI-26A (ø1.0 - ø2.6 mm)

26-Axis CNC Multi-Wire Forming Machine

A multi-functional forming machining, which enables a wide variety of wire processing, achieves high value-added forming and high productivity.

A new world in the spring forming machine industry begins.

Features

- 1. Free form-processing

-

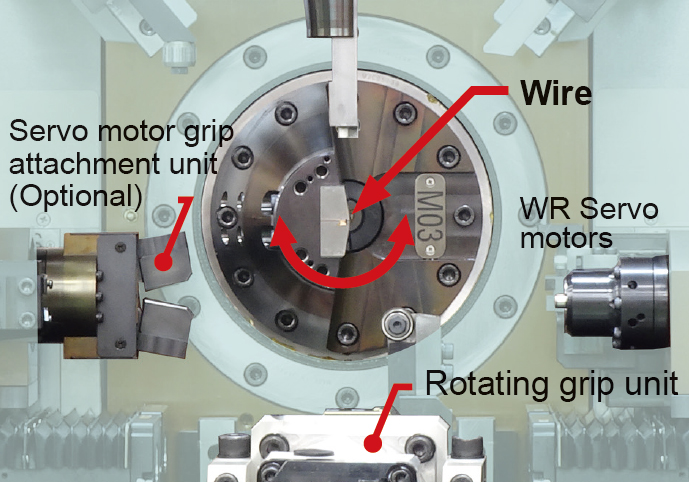

- Intuitive operation is made viable by having high-speed 3D slides on the top and bottom and high-speed dual slides on the left and right sides.

- This machine has dramatically expanded the application range of forming with the left and right double rotary (WR) servo motors, the upper rotary servo motor, the front rotating grip unit for secondary forming, and the newly developed wire rotary feed mechanism, all as standard equipment.

- 2. High-precision processing

-

- The newly developed bending sensor BS function results in high-precision bending.

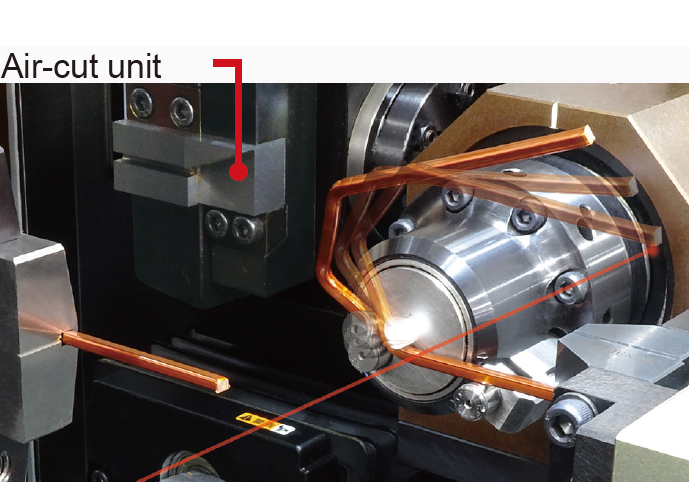

- With the high-rigidity air-cut unit, it cuts without a quill and leaves a beautiful cross section with quiet processing.

- The rotating unit and the double rotary servo motors facilitate post-processing after wiring cutting and support high value-added processing.

- 3. Reduced setup time due to high-repeatability

- No screw adjustment is needed when installing tooling. An CNC program performs advanced adjustment, greatly reducing setup time.

- 4. Improved operability with the MEC New Operation 2 (MNO2)

-

- The MEC original spring program MNO2 easily organizes important statistics about the machine, including program flow, operating status of each axis, inputs/outputs, jump, etc., as with our other spring machines.

- The program editing function has greatly evolved, and the navigation system function and touch screen make it easier to create programs and shorten the setup time.

- Highly efficient production is supported by a versatile production control screen and production data collection function.

- 5. Support for IOT

- The Wi-Fi function, which is standard in the newly developed spring forming program MNO2, allows you to check the operation status of the machine from your computer or smartphone through an optional centralized monitoring unit MB-1.

Movies

MEC NI-26A ø2.3 mm

Specifications

| Machine name | NI-26A |

|---|---|

| Wire diameter | ø1.0 ~ ø2.6 mm |

| Max stroke (Quil) | 150 mm |

| Max stroke (After grip) | 330 mm |

| Index | D/d 4 or more |

| Feed axis* | 0.0001 mm |

| Max feed speed | 118 m/min |

| Number of axes | 26 axis (Max 30 axis) |

| Solenoid valves | 5 pcs (Max 8 pcs) |

| Max air pressure | 0.5 MPa |

| Power source | 3-phase, AC 200V, 30A |

| Net weight | 4,150 kg |

| Control device | Windows |

| Software | MNO2 |

| Display | 21.5" full HD touch screen |

| External memory | USB Thumb drive |

| Temperature | 5 ~ 40°C |

*Resolution: It is a program input unit and does not represent accuracy.

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for non-Japanese specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us