AMADA Micro Welding Section

Laser Welders

Fiber Laser Welder

NEW

MF-C2000A-M/MC

High quality laser welding with high power 2000W multi mode laser

Features

Common features of MF-C2000A-M/MC

- ■Feature1 Active Heat Control

-

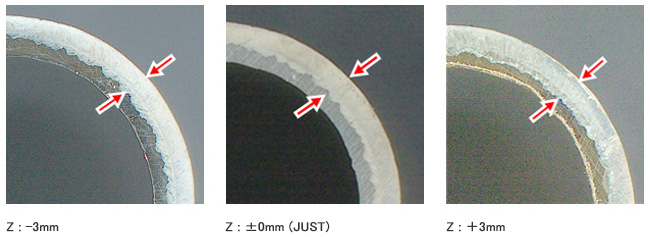

It's the new function to control laser output automatically based on the heat of the processing area.It enables to control laser output to get the heat that is already set up, by doing feedback to laser welder through the dedicated focusing unit.It enables to control of laser power based on the heat of the workpiece, different from the previous function that controls laser power based on the oscillator power.

The new function is suitable for the processing heat control which is important for welding or hardening. It is required to choose the option for the dedicated unit, and ML-6810C's specification.How the new function works?

Penetration will be more stable even if the focal point moves on Z-axis.

- ■Feature2 High power and compact design are implemented

- The dimension is the same as the previous model, and the output is twice higher.So, this new welder contributes to the design improvement of the production line owing to the compact design and downsizing.

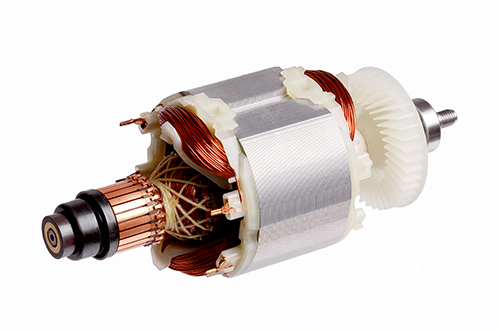

- ■Feature3 Applications

-

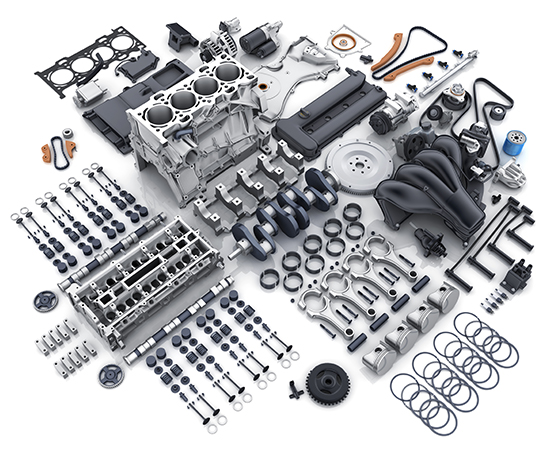

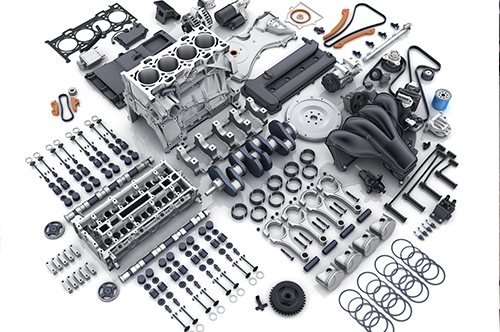

The new welder is recommended not only for seam or spot welding of stainless steel and other iron alloys but also high reflection materials as copper or aluminum.

In manufacturing of automobile parts or mechanical parts, the new welder realizes high-quality hardening and annealing by the Active Heat Control function.

Also, it shows good performance in the manufacturing of electronic parts for smartphones, electronic components, sensors, and engine parts for automobiles.Application

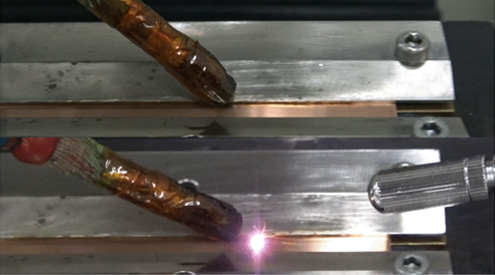

- ■Feature4 Reflection resistance structure

-

The machine is suitable for welding of high reflection materials as aluminum or copper, and suppress breakdown coming from high reflection. It enables to avoid the oscillator trouble by the reflection detecting sensor in the machine.

Comparison of reflection resistance structure

The picture above:Stopping laser emission imediatelly in other laser welder

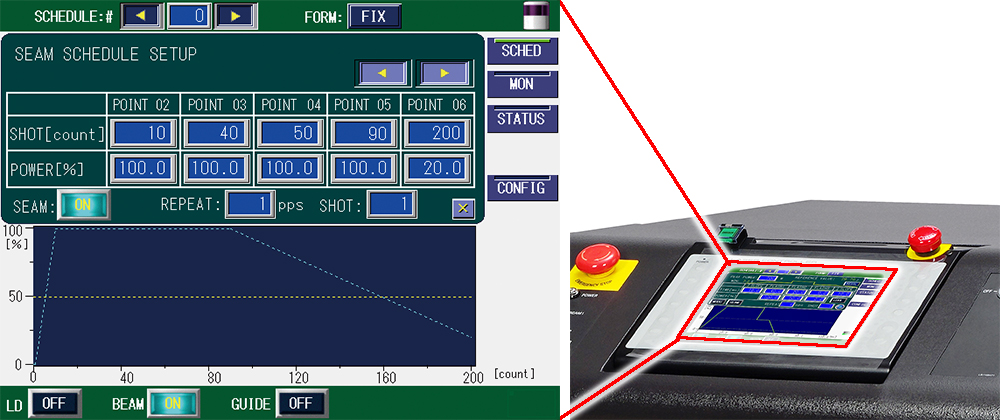

The picture below:Our laser welder doesn't stop laser emission even if it has reflection - ■Feature5 Useful user interface

-

A large LCD touchscreen allows to input settings easily.

Japanese and English are available.It can be used at a distance by extension cable.

User interface

- ■Feature6 Dedicated chiller

- The pairing with the dedicated chiller realizes its maximum ability.We highly recommend you to use our chiller. The chiller is delivered with its water piping, so there is no need for you to prepare accessories on your side.

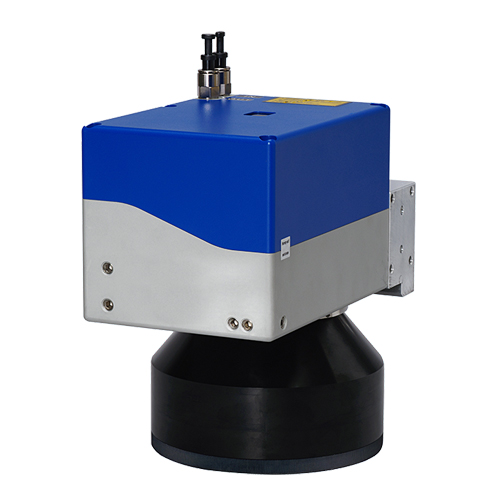

Features of MF-C2000A-MC

- ■Feature7 The integrated control of new galvo and welder.

-

The new welder enables to controll new galvo scanner and laser oscillation in one body. It's a simple configuration that the separated controller for galvo scanner is needless.Therefore, it reduces not only time for the maintenance but also problems generated by complex wiring.

Dedicated scanner head

CL-H201A*We can suggest high-precision correcing of position. Please ask us the details.

- ■Feature8 AutoPositionAlighment

- The new scanner head is operated by dedicated software "SW-Draw3".This software has a new position correcting function "Auto Position Alignment".

The new function corrects laser emitting position by detecting the incorrect position of the workpiece and calculating the correction amount based on registered design.So operators don't need to arrange the workpiece position and operating efficiency will be improved.

And the software has another function ""Gridwork"". It enables to take divided images in scanning area and to synthesize the images as a single data. The data can be used as draft in "Auto Position Alighment".

Those processes like registering image or drawing figures are needless.

Specifications

| Model | MF-C2000A-M/MC | |

| Maximum rated output / Minimum setting output | 2000W/200W | |

| Beam mode | Multi mode | |

| Pulse width | REPEAT | Standard:0.1~500.0ms(0.1ms step) Setting switching:0.05~500.00ms(0.01ms step) |

| CW | Standard:0.1~1000.0s(0.1s step) Setting switching:0.001~10.000s(0.001s step), | |

| 0.01~100.00s(0.01s step), 1~10000s(1s step) | ||

| Number of pulse | 1~1000pps | |

| Modulation function | 1~5000Hz(rectangular wave, triangular wave, sinusoidal wave) | |

| Output stability | ±2%(Ambient temperature:±5℃ max. at 5 to 40℃, Cooling water temperature:±1℃ max. 21 to 25℃, | |

| Cooling water flowrate:18 to 20ℓ/min, Laser emission time:8 hours max.) | ||

| Number of schedule | 256 | |

| Power supply | 3 phase AC200 to 240V(±10%), 50/60Hz, 40A | |

| Power consumption | Maximum 6.9kW / Standby 1.0kW | |

| Cooling | Water | |

| Ambient temperature / humidity | 5 to 40℃ / 20 to 85%RH(non-condensation) | |

| Dimension | 556(W) X 1,073(D) X 1,153(H)mm | |

| Weight | 250kg | |

| Dedicated chiller | Power supply:Single phase 200 to 230V, ±10%, frequency:50/60Hz, breaker rated current:20A | |

| Dimension:Approx. 377mm(W)×900mm(D)×976mm(H) | ||

| *Pairing with our manufactured welder is needed. | ||

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support