SH-3A (Single-point, ø0.08 - ø0.3 mm)

8-Axis CNC Single-Point Coiling Machine

The SH-3A, a multi-functional coiling machine with 1-point coiling, torsion attachment, and an initial tension servo, has further evolved. This coiling machine can now process an even greater range of torsion springs.

Features

- 1. 1-point coiling with a wire diameter of 0.08 to 0.3 mm

-

- Equipped with 8 standard axes: feed, cut, pitch, point, torsion, initial tension, coil front-back, and MSD.

- The standard MSD contact sensors allows for free length measurement. Servo motor control enables measurement in 1/1000 mm increments.

- Easier setup and greater speed than previous models, as the cut axis and torsion axis are separated.

- Suitable for high-speed production of ballpoint pen springs, torsion springs, and elliptical springs in addition to standard cylindrical springs.

- Optional ultra-thin wire attachment can be used to coil springs with a diameter of 0.08 mm or less.

- 2. Improved operability with the MEC New Operation 2 (MNO2)

-

- The MEC original spring program MNO2 easily organizes important statistics about the machine, including program flow, operating status of each axis, inputs/outputs, jump, etc., as with our other spring machines.

- The program editing function has greatly evolved, and the navigation system function and touch screen make it easier to create programs and shorten the setup time.

- The automatic function of coil length correction based on the MSD sensor length measurement method, the multi-functional production manager system makes production easy to control.

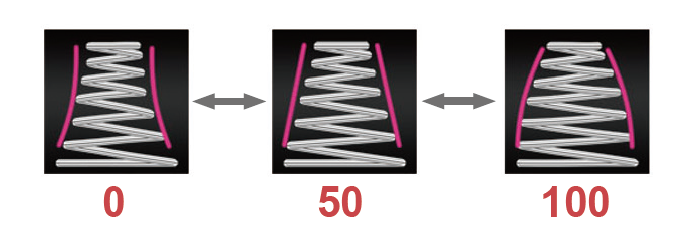

- 3. Taper synchronization constant

-

Enables the taper tilt to be managed with a value from 0 to 100.

Suitable for load adjustment in addition to shape adjustment, as fine adjustment can be performed in 100 levels.

- 4. 3-types of wire guides

-

The SH-3A has 3-wire guides with different lengths:

- Short guide with a guide length of 23 mm

Provides greater accuracy for short springs due to its shorter guide length, while retaining the same clearance length as a standard wire guide. - Standard wire guide with a guide length of 30 mm

Enables use of all tools available for the previous SH-3, SH-3II wire guide. - Wire guide for ultra-thin wires with a guide length of 16 mm

Enables coiling of wires with a diameter of 0.08 mm or less.

- Short guide with a guide length of 23 mm

- 5. Optional Equipment

-

- Ultra-thin wire attachment

- 3-dimensional bending servo unit to improve stability and speed when creating antenna springs

- Capacitance level sensor

- IS-1 shape detection unit with camera

Specifications

| Machine name | SH-3A |

|---|---|

| Wire diameter | ø0.08 ~ ø0.3 mm |

| Wire diameter with ultra fine wire attachment (Optional) | ø0.03 ~ ø0.08 mm |

| Outer coil diameter | ø10 mm |

| Index | D/d 4 or more |

| Feed axis* | 0.0001 mm |

| Max feed speed | 85 m/min |

| Cut axis* | 0.001° |

| Pitch axis* | 0.0001 mm |

| Point axis* | 0.0001 mm |

| Torsion attachment axis* | 0.001° |

| Initial tension axis* | 0.0001 mm |

| Arbor axis* | 0.0001 mm |

| 3D bending servo slide unit* (Optional) | 0.001° |

| Solenoid valves | 4 pcs (Max 8 pcs) |

| Max air pressure | 0.5 MPa |

| Power source | 3-phase AC 200V, 15A |

| Net weight | 380 kg |

| Control device | Windows |

| Software | MNO2 |

| Display | 15.6" Full HD touch screen |

| External memory | USB Thumb drive |

| Temperature | 5 ~ 40°C |

*Resolution: It is a program input unit and does not represent accuracy.

Related products

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for overseas specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us