RHQ 2-axis servo robot

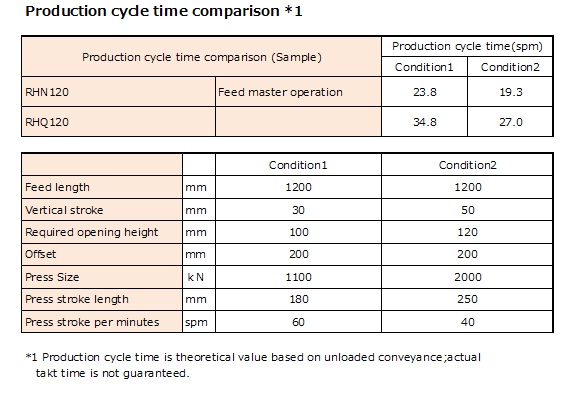

The RHQ120 robot was launched as high speed model of RHN120.

It provides best-in-class transfer speed through symbiotic control.

Features

- ■ Features(1) : Advanced RHQ transfer robot offers high speed, stability and improved interface.

-

- It was launched to the market as a high-speed model of the existing RHN120

- It can set the optimum synchronized condition for each press through the teaching motion feature.

(Able to save job number of each part.) - It can reduce delay time at T.D.C. of the press through symbiotic control.

- ■ Features(2) : It can improve the productivity of a press line greatly with the reduction of idle time.

-

The way for enhancing productivity of press line is to control idle time between robot and press and increase transfer speed of robot. Continuous mode without stopping press (synchronized operation with stamping press) has proven to be the best for improving performance. Although ideal cycle time can be obtained with this method, it is unsuitable for press line that requires frequent set up due to high mix and low volume production, because complicated calculation or adjustment for each product is required. In RHQ robot line, the cooperative control adjusting timing between robot and press individually with easy-to-use teaching function while maintaining realistic feed master operation is attainable.

- ■ Features(3) : Advanced teaching system

-

Able to set feed position and fine-tune while checking actual movement.

Moreover mobile teaching pendant enables user to move closer when inputting data.

Movies

Specifications

| Model | RHQ120S1 | RHQ120L1 | RHQ180S1 | |

|---|---|---|---|---|

| Feed length | mm | 1,000 ~ 1,200 | 1,201 ~ 1,500 | 1,501 ~ 2,000 |

| Vertical stroke | mm | 10 ~ 100 | 10 ~ 100 | 10 ~ 100 |

| Cycle time *1 | sec | 1.5 ~ *2 | 1.8 ~ *3 | 2.4 ~ *4 |

| Max. workpiece weight *5 | kg | 4.0 x 2 | 4.0 x 2 | 4.0 x 2 |

| Repeatability *6 | mm | ±0.3 | ±0.3 | ±0.3 |

| Workpiece pick up | Vacuum/Magnet | |||

| Weight | kg | Aprox. 350 | Aprox. 350 | Aprox. 500 |

*1 Cycle time may vary with workpiece shape, feed length, vertical stroke, etc.

*2 Value when feed length is 1200 mm and vertical stroke is 50 mm.

*3 Value when feed length is 1500 mm and vertical stroke is 50 mm.

*4 Value when feed length is 2000 mm and vertical stroke is 50 mm.

*5 Max. workpiece weight: total weight, including finger and workpiece

*6 Precision using automated operations. Value may vary by workpiece and transfer conditions.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us