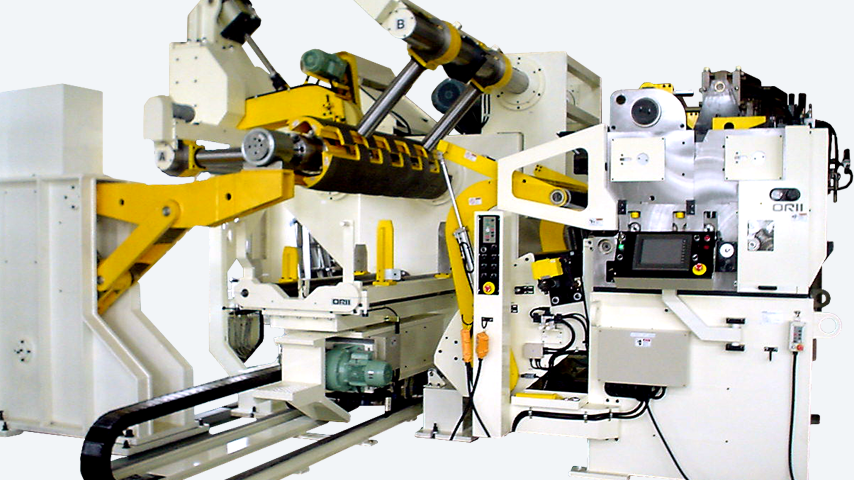

Large-Scale Straightener/Feeder

Our PQ Series of large-scale straightener/feeders supports stock widths of up to 1,500 mm, 1,700 mm, or 1,900 mm, and stock thicknesses of up to 3.2 mm.

Coils can also be automatically inserted (loaded and threaded) as with a coil feeder line (optional).

Features

- ■ Features(1) : Includes roll open mechanism

-

A maximum opening of 20 degrees is possible, centered on the eccentric shaft on the exit side. The large opening area enables easy roll cleaning, and internal mechanisms are bright and easy to check, greatly improving maintenance.

- ■ Features(2) : 9 work rolls

-

This product has 9 work rolls, enabling a wide range of stock to be supported while also allowing a generous maximum thickness of 3.2 mm. With 9 rolls, this product takes flatness to the next level.

Specifications

PQS Series (side gear drive)

| Model | LCC15PQS | LCC17PQS | LCC19PQS | |

|---|---|---|---|---|

| Stock Width | mm | 300~1,500 | 300~1,700 | 300~1,900 |

| Stock Thickness | mm | 0.8~3.2 | 0.8~3.2 | 0.8~3.2 |

| Coil Mass | kg | Max.10,000 without mandrel support |

Max. 15,000 with mandrel support |

Max. 15,000 with mandrel support |

| Coil O. D. | mm | 700~1,500 | 700~1,500 | 700~1,500 |

| Coil I. D. | mm | 508 | 508 | 508 |

| Feed Length | mm | Max.1,000 | Max.1,000 | Max.1,000 |

| Line Speed | m/min | Max.30 | Max.30 | Max.30 |

| Number of Work Rolls | ― | upper 5 / lower 4 | upper 5 / lower 4 | upper 5 / lower 4 |

| PLC | MITSUBISHI | MITSUBISHI | MITSUBISHI | |

| Mandrel Expansion | Hydraulic | Hydraulic | Hydraulic | |

| Power | V | 200/220 50/60 Hz 400/440 50/60 Hz |

200/220 50/60 Hz 400/440 50/60 Hz |

200/220 50/60 Hz 400/440 50/60 Hz |

| Operating Air | Mpa | 0.49 | 0.49 | 0.49 |

PQU Series (universal joint drive)

| Model | LCC15PQU | LCC17PQU | LCC19PQU | |

|---|---|---|---|---|

| Stock Width | mm | 300~1,500 | 300~1,700 | 300~1,900 |

| Stock Thickness | mm | 0.8~3.2 | 0.8~3.2 | 0.8~3.2 |

| Coil Mass | kg | Max. 10,000 without mandrel support |

Max. 15,000 with mandrel support |

Max. 15,000 with mandrel support |

| Coil O. D. | mm | 700~1,800 | 700~1,800 | 700~1,800 |

| Coil I. D. | mm | 508 | 508 | 508 |

| Feed Length | mm | Max.1,500 | Max.1,500 | Max.1,500 |

| Line Speed | m/min | Max.40 | Max.40 | Max.40 |

| Number of Work Rolls | ― | upper 5 / lower 4 | upper 5 / lower 4 | upper 5 / lower 4 |

| PLC | MITSUBISHI | MITSUBISHI | MITSUBISHI | |

| Mandrel Expansion | Hydraulic | Hydraulic | Hydraulic | |

| Power | V | 200/220 50/60 Hz 400/440 50/60 Hz |

200/220 50/60 Hz 400/440 50/60 Hz |

200/220 50/60 Hz 400/440 50/60 Hz |

| Operating Air | Mpa | 0.49 | 0.49 | 0.49 |

Note: The above table is applied to the pit specifications.

Straightening Performance

LCC19PQS

| Tensile strength | 40kgf/mm2 | 50kgf/mm2 | 60kgf/mm2 | 70kgf/mm2 | 80kgf/mm2 | |

|---|---|---|---|---|---|---|

| 392N/mm2 | 490N/mm2 | 588N/mm2 | 686N/mm2 | 784N/mm2 | ||

| Yield point stress | 245N/mm2 | 306N/mm2 | 367Nmm2 | 428N/mm2 | 490N/mm2 | |

| Stock Thickness | 0.8 | 1,900 | (1,900) | (1,900) | (1,900) | (1900) |

| 1.0 | 1,900 | (1,700) | ||||

| 1.2 | 1,900 | 1,810 | (1,400) | |||

| 1.6 | 1,780 | 1,340 | 1,040 | |||

| 2.3 | 1,670 | 1,200 | 900 | 700 | ||

| 2.8 | 1,340 | 960 | 730 | 570 | ||

| 3.2 | 1,580 | 1,150 | 830 | 630 | 490 | |

LCC19PQU - for the multi-servo 55kW x 3 units (165kW) / option

| Tensile strength | 40kgf/mm2 | 50kgf/mm2 | 60kgf/mm2 | 70kgf/mm2 | 80kgf/mm2 | |

|---|---|---|---|---|---|---|

| 392N/mm2 | 490N/mm2 | 588N/mm2 | 686N/mm2 | 784N/mm2 | ||

| Yield point stress | 245N/mm2 | 306N/mm2 | 367Nmm2 | 428N/mm2 | 490N/mm2 | |

| Stock Thickness | 0.8 | 1,900 | (1,900) | (1,900) | (1,900) | (1,900) |

| 1.0 | 1,900 | 1,900 | ||||

| 1.2 | ||||||

| 1.6 | 1,900 | 1,900 | ||||

| 2.3 | 1,750 | 1,530 | ||||

| 2.8 | 1,650 | 1,370 | 1,180 | 1,030 | ||

| 3.2 | 1,580 | 1,260 | 1,050 | 900 | 790 | |

Note: The tensile strength is the reference value calculated based upon the yield point stress.

Check straightening performance in accordance with the yield point stress.

Note: Flatness may be unobtainable with the value in parenthesis.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us