For AC precision spot / Series / Fusing welding: MIB-300A/600A

Use AC transformer and improve heat efficiency.

Reduce magnetize and peltier effect on work piece.

Features

- ■ Able to keep on using AC welder transformer if you already have

-

No need to buy new weld head and transformer if you are already using AC welder for production

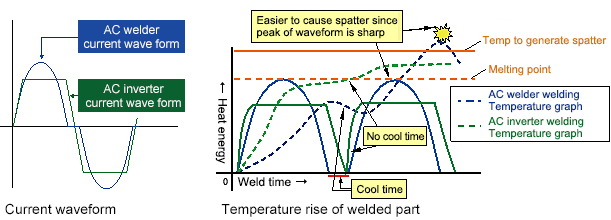

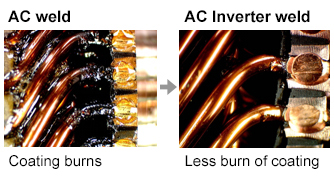

- ■ Reduce burn of coating materials while fusing

-

-

- ■ Reduce slant abrasion of electrode and unequal size of welding nugget

-

Reduce slant heat on one material while welding different material (peltier effect), reduce slant abrasion of electrode and unequal size of welding nugget.

- ■ Reduce magnetize of work piece around electrode

-

Reduce magnetic material around welding current being magnetized.

- ■ Add secondary constant current control

-

Since welding current will be monitored and controlled directly, able to have higher current control than primary constant current control.

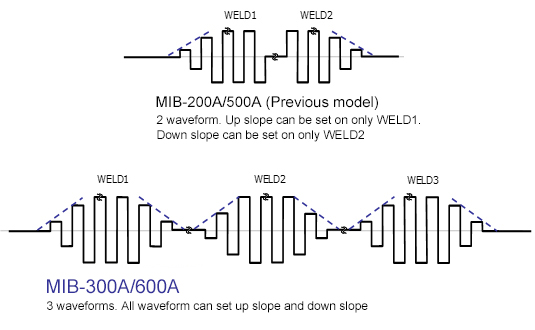

- ■ Increase number of maximum pulsation

-

Previous unit: 9 times pulsation maximum → MIB-300A/600A: Maximum 20 times for each WELD1 to WELD3

Since it suppresses the rapid heating to the work by repeating the welding time and the pause time, it becomes easier to control the amount of displacement compared with continuous welding for a long time. - ■ Able to set interrupt, up slope and down slope for all waveform (WELD1 to WELD3)

-

Interrupt function (Stop current when displacement value reaches to set level, go on to next step) will avoid work piece to be squashed, able to have more precise setting for welding condition.

-

Specifications

| Models | MIB-300A-00-00 | MIB-300A-00-01 | MIB-600A-00-00 | MIB-600A-00-01 | |

| Power requireents | 3 phase AC200~240V±10%(50/60Hz) | 3 phase AC380~480V±10%(50/60Hz) | 3 phase AC200~240V±10%(50/60Hz) | 3 phase AC380~480V±10%(50/60Hz) | |

| Maximum output current | 300A | 600A | |||

| Number of schedules | 255 | ||||

| Output frequency | 50, 53, 56, 59, 63, 67, 71, 77, 83, 91, 100, 111, 125, 143,167, 200, 250, 294, 417, 500Hz (Initial setting is 63 Hz.) Frequencies in bold are available only when FREQ MODE (START) is set to PWM-OFF. |

||||

| Control method | Primary constant-current peak value control / Secondary constant-current peak value control / Secondary constant-current effective value control |

||||

| Timer setting (255) |

SQUEEZE DELAY | 0000 to 9999ms | |||

| SQUEEZE | 0000 to 9999ms | ||||

| UP SLOPE 1,2,3 | 00.0 to 99.5cyc | ||||

| WELD 1,2,3 | 00.0 to 99.5cyc | ||||

| DOWN SLOPE 1,2,3 | 00.0 to 99.5cyc | ||||

| COOL 1,2 | 00.0 to 99.5cyc | ||||

| HOLD | 00000 to 20000ms | ||||

| OFF *1 | 0 or 0010 to 9990ms | ||||

| Transformer turn ratio | 1.0 to 199.9 | ||||

| Pulsation setting | 01 to 20 | ||||

| Valve setting | 2valves (VALVE1, VALVE2) | ||||

| Setting range | 40kA range | - | 02.0 to 40.0kA | ||

| 20kA range | 0.1kA to 20.0kA | 01.0 to 20.0kA | |||

| 10kA range | 0.50 to 9.99kA | 0.50 to 9.99kA | |||

| 5kA range | 0.05 to 5.00kA | 0.05 to 5.00kA | |||

| Monitor display | Current | 00.0 to 99.9kA/0.00 to 9.99kA | |||

| Voltage | 0.00 to 9.99V | ||||

| Cooling method | Cooling with air | Cooling with water Flow rate: 2L/min Water temperature: 35°C max. | |||

| External communication | RS-232C/ RS-485(Simplex and duplex) | ||||

| Operating environment | Ambient temperature | +5 to +40℃ | |||

| Humidity | 90% max.(no condensation) | ||||

| Altitude | 1000m以下 | ||||

| Mass | 16.5kg | 38kg | |||

*1: Set at the factory

Transformers that are selectable

| For MIB-300A | ||||

| Model | MT-510AC | MT-520AC | MT-530A*1 | MT-25 |

| Rated capacity | 1kVA | 3.2kVA | 6.0kVA [4.2kVA] | 11.1kVA |

| Rated primary voltage | 200VAC ±10%(50Hz/60Hz) | 200VAC ±10%(50Hz/60Hz) | 200VAC ±10%(50Hz/60Hz) | 200VAC ±10%(50Hz/60Hz) |

| No-load secon- dary voltage |

1.2V/1.8V/2.5V/3.5V | 2.5V/3.2V/4.0V/5.0V | 2.7V[2.2V]/3.4V[2.8V]/ 4.3V[3.6V]/5.3V[4.4V] |

2.6V/4.0V(paralell)/ 5.3V/8.0V(straight) |

| Trans- former turns ratio |

167:1/111:1/80:1/57:1 | 80:1/63:1/50:1/40:1 | 74:1/59:1/47:1/38:1 | 77:1/50:1/38:1/25:1 |

| Maximum welding current | 1600A | 3700A | 6600A [5500A] | 8000A |

| Duty cycle | 1.5% or less | 2% or less | 1.5% or less | 1.5% or less |

| Cooling method | Air cooling | Water cooling | ||

| Mass | 20kg | 35kg | 52kg | 60kg |

| Dimen- sions (mm) *2 |

193(W) × 284(D) × 175(H) | 182.5(W) ×358(D) × 197(H) | 228(W) × 370(D) ×244(H) | 180(W) × 370(D) × 240(H) |

*1: Values at 60 Hz input are indicated in brackets [ ].

| For MIB-600A | ||||

| Type | ー | Tap less | ||

| Model | WT-A56241-220 | WT4N-115-205-H-A WT4N-115-205-Z-A |

WT4N-125-206-H-A WT4N-125-206-Z-A |

WT4N-175-206-H-A WT4N-175-206-Z-A |

| Rated capacity | 56kVA | 115kVA | 125kVA | 175kVA |

| Rated primary voltage | 220(50Hz) | 200V(50Hz) | 200V(60Hz) | 200V(60Hz) |

| No-load secondary voltage | 9.1V | 9.5V | 10.5V | 13.3V |

| Transformer turns ratio | 24:1 | 21:1 | 19:1 | 15:1 |

| Cooling method | Water | |||

| Mass | 45.5kg | 123kg | 116kg | 140kg |

| Dimensions(mm)*2 | 125(W) × 515.3(D) ×200(H) |

197(W) × 598(D) ×260(H) |

197(W)×578(D) ×260(H) |

197(W) × 628(D) × 260(H) |

| For MIB-600A | |||||

| Type | Tap changing | ||||

| Model | WT4T-70-200-H-A WT4T-70-200-Z-A |

WT4T-90-415-H-A WT4T-90-415-Z-A |

WT4T-110-446-H-A WT4T-110-446-Z-A |

WT4T-135-446-H-A WT4T-135-446-Z-A |

WT4T-190-446-H-A WT4T-190-446-Z-A |

| Rated capacity | 70kVA | 90kVA | 110kVA | 135kVA | 190kVA |

| Rated primary voltage | 200V(50/60Hz) | 415V(50Hz) | 440V(60Hz) | 440V(60Hz) | 440V(60Hz) |

| No-load secondary voltage | TAP1, 6.4V TAP2, 8.0V |

TAP1, 6.3V TAP2, 7.6V |

TAP1, 7.4V TAP2, 9.1V |

TAP1, 9.7V TAP2, 11.5V |

TAP1, 12.2V TAP2, 14.6V |

| Transformer turns ratio | TAP1, 31:1 TAP2, 25:1 |

TAP1, 65:1 TAP2, 54:1 |

TAP1, 59:1 TAP2, 48:1 |

TAP1, 45:1 TAP2, 38:1 |

TAP1, 36:1 TAP2, 30:1 |

| Cooling method | Water | ||||

| Mass | 106kg | 106kg | 100kg | 119kg | 134kg |

| Dimensions(mm)*2 | 197(W) × 564(D) × 260(H) | 197(W) × 564(D) × 260(H) | 197(W)×544(D)× 260(H) |

197(W) ×604(D) × 260(H) | 197(W) × 654(D) × 260(H) |

*2: Not including projections

Models H and Z of the tapless type and tap changer type indicate the core material, and when used in an AC inverter type, the Z type is recommended.

H: Standard type Z: Low iron loss type

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support