20W/50W ML-7320GL/7350GL

To provide a fully air cooled high-powered, high-quality laser in a compact body. Beautiful black marking and deep engraving at high speed.

The highest power in AMADA's fiber laser marker series! High-speed marking shortens takt times.

Plaese click here to get the manual

The ML-7320GL/7350GL is a fully-air cooled fiber laser marker and the best suited for marking on metal parts, engraving on aluminum and stainless steel. As the beam quality improves from that of the conventional models, marking quality becomes much better than before. Great oscillation efficiency, which is one of the characteristics fiber laser has, supports saving of energy. Its 50W oscillator makes marking speed high and contributes to improvement in productivity.

In addition, the marking software installed is LM Draw 6 which is compatible with the conventional models. No troublesome work is necessary at replacement of the unit.

- The highest power oscillator in AMADA's fiber laser markers enables high-speed deep engraving of aluminum and stainless steel.

- Improved beam quality makes marking more precise.

- Compact head unit. Space saving.

- High performance marking software LM Draw 6.

- CF card slot is equipped. It makes it easy to transfer, share and save the data used in the previous models.

- Multiple axes stage control with an optional motion control of X, Y, Z and θ axes.

- Lower maintenance cost according to full air cooling and low power consumption.

- Long-life LD unit reduces maintenance costs.

- IP5X structure.

- RoHS2 is certified.

Features

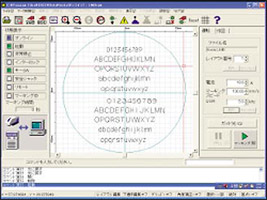

- ■ Marking software LM Draw 6

-

Well-received marking software LM Draw 6 dedicated for DL series is equipped. You can freely design drawings, letters and 2D codes to laser mark. In addition, the software is compatible with the previous version and in addition, it equipes the importing function to use former data.

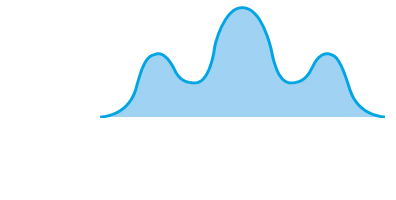

- ■ Great beam quality

-

High quality beam profile.

- ■ Compact head unit

-

The whole length of the head unit is 40% more shorter than the conventional model (ML-7340CL). *Expander unit is excluded.

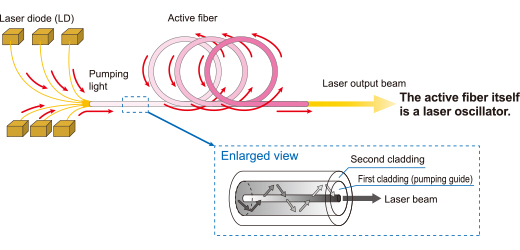

Fiber laser

Features high energy conversion efficiency and high beam quality and allows very fine marking and processing.

Automatic backup function

Time and counts of operation sets are backed-up in a log file automatically.

Multi mode laser

It's effective in processing as oxidation marking that needs energy in wide area.

Power image

Fully air-cooled

Cooling by a fan motor and electron cooler obviates the need for cooling water and water filter.

LMDraw

The opereating software equips various abilities with simple monitor.

Saving maintenance

It cuts down man-hour for maintenance drastically, according to optimization of components.

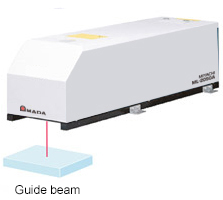

Guide beam

Indicates the marking start position and processing area of the workpiece.

Production Samples

Clear 2D marking on aluminum.

Deep engraving of aluminum. (1.8mm deep, 40 times marking)

Specifications

Marking area

| fθ lens | f75 *1 | f100 | f150 | f160 | f270 | f350 |

| Scanning method | Galvanometer scanner | |||||

| Marking area (mm) | Φ37 | Φ76 | Φ115 | □94 | □134 | □192 |

| Working distance (mm) | 93 | 108 | 170 | 176 | 313 | 412 |

| Position resolution (μm) *2 | 1 | 2 | 2 | 2 | 4 | 4 |

| Marking speed (mm/s) *3 | 0.01 to 5000 | 0.01 to 7000 | 0.01 to 10000 | 0.01 to 11000 | 0.01 to 18000 | 0.01 to 20000 |

*1 Available for the standard head unit only.

*2 Computed value. Not the actual position accuracy.

*3 Computed value. Confirm the appropriate speed for marking during actual marking operations.

Specifications

| Model | ML-7320GL | ML-7350GL |

| Laser type | Yb Fiber Laser | |

| Oscillation wavelength | Fundamental wavelength | |

| Oscillation mode | Multi mode | |

| Maximum output | 20W(Output from oscillator) | 50W(Output from oscillator) |

| Oscillation type | Pulse oscillation | |

| Repetition frequency | 20k to 200kHz | 50k to 200kHz |

| Guide beam | Red LD laser | |

| Marking speed | 550 letters per second (Height of letter: 1mm, f=160) | |

| External communication terminals | USB1.1 (Full speed), RS-232C (Option), Compact flash card | |

| Cable length bet. Head and control unit | 3m (Fix) | |

| Cooling method | Fully air cooled | |

| Power supply | Single-phase: 100-240 V AC -10%/+6%, Auto switching: 50/60 Hz | |

| Power consumption | 270W or less | 330W or less |

| Marking software (PC) *1 | LM Draw 6 • Windows 7 Professional 32/64 bit Japanese/English version(SP1), • Windows 8.1 32/64 bit Japanese/English version, • Windows 10 Pro 64 bit Japanese/English version |

|

| Font | TrueType font, DIN30640, JIS Z 8905, JIS Z 8904, JIS Z 8903, OCR-A, OCR-B, Round hand, Round gothic | |

| Marking characters | Alphabet, Number, Katakana, Hiragana, Chinese character (Round gothic of JIS first standard and second standard), Symbol | |

| Supported file formats | DXF(AutoCAD 2006 version or earlier), BMP, JPEG, GIF, TIFF | |

| Code types *2 | Code39, Code128, ITF, Data matrix, QR code, Micro QR code | |

| Environmentally-resistant strengthened head | Standard Head: IP5X Water and Oil Proof Head Unit (option): IP67 and IPXXG (the JIS standard) *3 | |

| Ambient temperature | 5 to 35 ℃ (non-condensing and non-freezing) | |

| Ambient humidity | 40 to 80% RH (non-condensing and non-freezing) | |

| Mass | <Control unit> 26kg, <Head unit> 4kg Water and Oil Proof Head Unit (option): approx. 7kg | |

*1 Windows is a registered trademark and a product of Microsoft, Inc.

*2 Data Matrix is a registered trademark and a product of International Data Matrix, Inc. QR code is a registered trademark and a product of Denso Wave Co., Ltd.

*3 No warranty is given to dust water and oil proofing in any environment.

* Specifications are subject to change without notice.

Applications

Marking on machine parts, tools, electronic parts, automotive parts and medical equipment; deep engraving of aluminum and stainless steel; cutting and drilling.

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support