5W ML-8150A

Perfect for welding of gold and copper!

The world's highest peak power of 1.5kW! High-power laser enables solderless welding of precision parts!

Plaese click here to get the manual

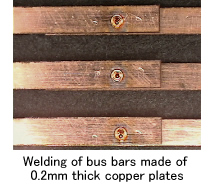

ML-8150A provides 5W of maximum power, which is upgraded more than twice compared with the conventional machine. It enables faster and deeper welding of even copper and gold, which have high reflectance to YAG fundamental laser and are hard to be welded.

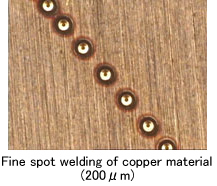

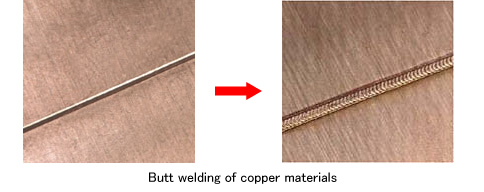

Further, its beam becomes so thinner than the conventional one that deeper, thinner, and more beautiful welding can be achieved.

- Solid welding of cupper and gold by SHG laser.

- 5W power achieving deeper penetration and faster operation.

(Power density is nine times as high as the conventional model.) - Ø0.2mm fiber enabling high quality precision welding.

- High speed pulse control to shorten the takt time.

(Pulse frequency is three times as high as the conventional model.) - Two simultaneous energy share enabling two simultaneous processings and processing from two different angles.

- AMADA MIYACHI's original power feedback feature.

- Easy-to-use jog dial.

Standard Features

Features

- ■ Why can laser weld copper and gold?

-

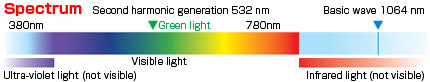

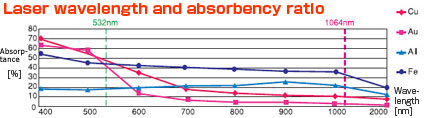

SHG laser is green-colored visible light with wavelength of 532nm, which is a half of fundamental laser (1064nm).

-

Absorption of laser into copper and gold is 4.5 to 20 times higher than fundamental laser so that it is possible for laser to weld copper and gold.

- ■ Expand the Environmentally-friendly Method of Welding

-

Manufacturing by lead-free soldering and solder-less joining methods is recently required considering protection of the environment. Especially for electronic device manufacturing, their reliabilities have been a significant issue lately.

The Solution is... Laser Welding!

- Heat-affected area can be reduced so that parts with weak heat resistance can be welded.

- No flux is necessary.

- No solder creeping.

- Size and weight of parts can be minimized as solder is reduced.

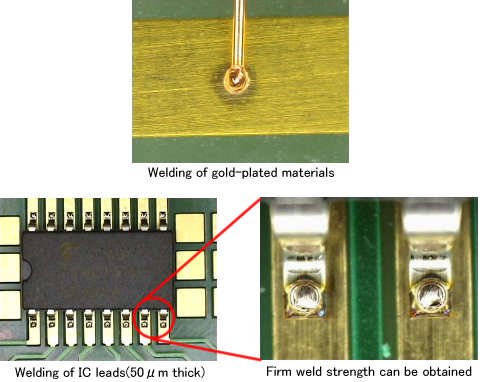

- ■ Applications

-

Welding of electronic devices, electric devices, IC leads, gold-plated patterns and more.

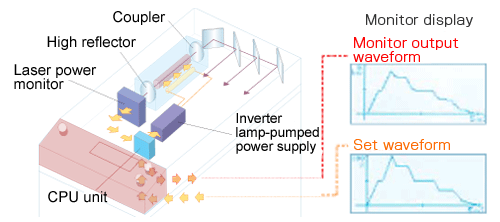

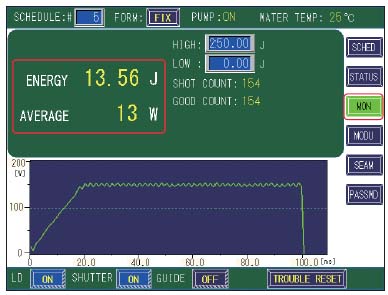

Real-time Power Feedback Control

The laser output in the lamp-pumped module is monitored in real time. The monitored laser output is compared with the set waveform and power is fed back in real time, varying the energy input to the lamp to reproduce the set waveform and obtain the ideal laser output waveform.

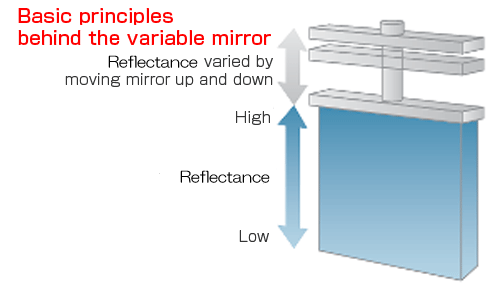

Variable mirrors

These mirrors eliminate laser power loss and improve branch balance.

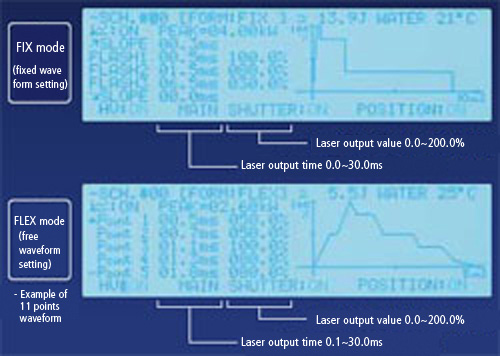

Waveform control

Equipped with a "fixed mode" that features three-level waveforms, and a "flex mode" to provide more complex waveforms.

Power monitor

Laser energy (J) and average power (W) are monitored to detect abnormalities.

External communications

Configuration of parameters and monitoring of performance can be carried out from a separate location.

- Type: RS-485 compliant, asynchronous, full duplex

- Data speed: 9600, 19200, 38400 bps

Forced Air Cooling System

The air cooling system is available.

No water and piping are necessary.

Production Samples

Specifications

| Model | ML-8150A | |

| Oscillation wavelength | 532nm | |

| Laser power | Maximum average power | 5W |

| Maximum output energy | 4J/P | |

| Maximum peak power | 1.5kW | |

| Controlling power | Pulse width | 5ms(0.02ms step) |

| Pulse repetition rate | 1 to 30pps | |

| No. of programmable schedules | 32 | |

| Counter | Total number of outputs | 9 digits |

| Number of acceptable outputs | 9 digits | |

| Optic fiber | Φ0.2mm (Usable is Φ0.2~1.0mm SI type optical fiber) | |

| Fiber optic delivery | Up to 2 deliveries of laser output, including powersharing and timesharing, are available. (Option) |

|

| External communication function | RS-485 | |

| Power requirements | Single-phase 200V, 220V, 240V AC +10%, -15%, 50/60Hz | |

| Heat exchange method | Forced air cooling | |

| Dimensions | 430(W) X 869(D) X 822(H) | |

| Weight | 120kg | |

*Specifications subject to change without notice.

Applications

Welding of electronic devices, electric devices, IC leads, gold-plated patterns and more.

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support