AMADA PRESS SYSTEM

Spring Machines

Torsion Spring Machines

NEW

LM-26A (ø1.2 ~ ø2.6 mm)

15-Axis CNC Torsion Spring Machine with Rotating Wire

Intuitive operation has been made possible with a wire rotation mechanism and eight equipped processing slides as standard options.

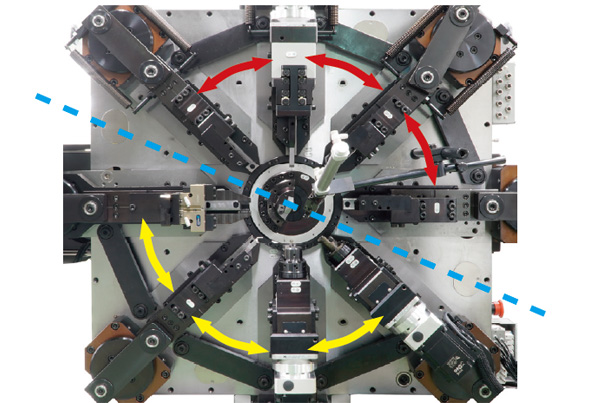

This machine is equipped with two swinging axes, which control the left and right movement of the facing slides independently.

Features

- 1. Improved productivity with shortening setup time and reducing work

-

- The double swing axis divided into upper and lower parts numerically controls the left-right movement of the slide. The program achieves high repeatability and contributes to shortening the setup time. It can also be fixed to any slide.

- The 15-axis control is equipped with feed, rotated wire and quill, two swings, eight slides, and two R-servos.

- All slides utilize a crank mechanism to achieve high speed. The crank mechanism can also be used to change the setting to constant speed operation according to the processing needs.

- The addition of small rotary (R) servo slides makes changeover easy.

- This machine integrates a high-speed wire rotation mechanism, which suppresses vibration to the utmost limit.

- Although the spinner tool is compact, the distance between the shaft and the outer pin can be adjusted. This eliminates the need to replace the pin for each wire diameter, reducing setup time and running costs.

- 2. Improved operability with the MNO2 (MEC New Operation 2) programming software

-

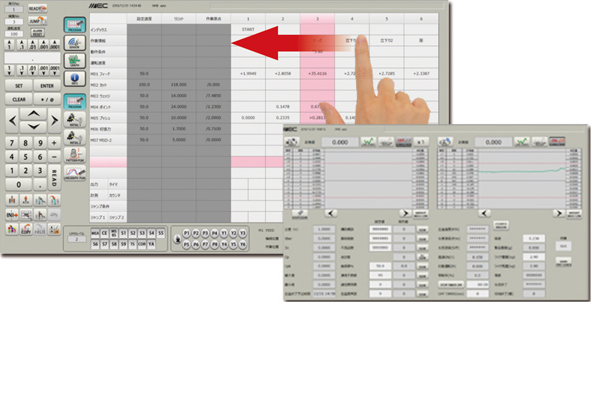

- The MEC original MNO2 software easily organizes important statistics about the machine, including program flow, operating status of each axis, input/output, and jump, etc., as with our other spring machines.

- The motor sensor system makes every slide a sensor. It is possible to measure the presence/absence judgment with a touch sensor, coiling angle, free length, etc. in 0.001 mm units. The measurement results are displayed in tables and graphs, and easy correction control for each axis is possible.

- Highly efficient production is supported by a versatile production management and data collection functions.

- 3. Main options

- We have a wide range of optional units to meet the varied needs of the user in the areas of post-processing and measurement.

- 3D slide unit--allows the slide to move forward (up to 200 mm)

- Outer coil diameter servo unit--adjusts diameter with a servo motor

- Swing unit--that controls the sliding of the left and right parts in addition to the top and bottom

- Air nipper unit--prevents wear and breakage of the quill

- Air grip--enables post-processing

- Reverse bending slide--bends in direction of the machine front

- Grip head unit--enables wire grip with R-servo

- Capacitance sensor--measures free coil length

- Camera sensor--measures free coil length, outer coil diameter, angle, etc.

- 4. Support for IOT (optional)

- The operating status of machine can be monitored through mobile phones or computers, and regular maintenance with preventive maintenance functions can contribute to improved production efficiency.

Movies

LM-26A Wire-ø: ø2.0 mm, Torsion spring processing samples (6 types)

Specifications

| Machine name | LM-26A |

|---|---|

| Wire diameter | ø1.2 ~ ø2.6 mm |

| Max twirl distance | ø100 mm |

| Index | D/d 4 or more |

| Feed axis* | 0.0001 mm |

| Max feed speed | 117 m/min |

| Tool slide | 6 pcs |

| R-servo slide | 2 pcs |

| Max air pressure | 0.5 MPa |

| Power source | 3-phase, AC 200V, 20A |

| Net weight | 1700 kg |

| Control device | Windows |

| Software | MNO2 |

| Display | 15.6” Full HD touch screen |

| External memory | USB Thumb drive |

| Temperature | 5 ~ 40°C |

*Resolution: Program input unit, which does not represent accuracy.

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for overseas specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us