SH-3AG (Dual-point, ø0.08 ~ ø0.23 mm)

8-Axis CNC Dual-Point Coiling Machine for Guide Wire Processing

A high-speed, high-quality production system specialized in the processing of guide wires for medical catheters.

Achieves a production speed that greatly exceeds conventional coiling production methods.

Features

- 1. Achieving required quality for guide wires

-

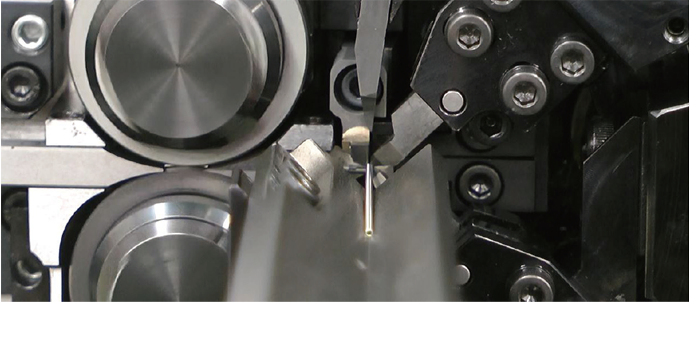

- The newly developed 2-point coiling unit disperses friction during coiling and contributes to stabilization of the initial coil tension.

- Compared to the single-point method, the trace of the coil inner diameter is greatly reduced without an arbor.

- The optional rotary discharge shooter PR-2, which receives the long coil wire, suppresses runout when manufacturing long coils, eliminates the problem of discharge methods, and supports high-precision coiling.

- 2. Supports automated production

-

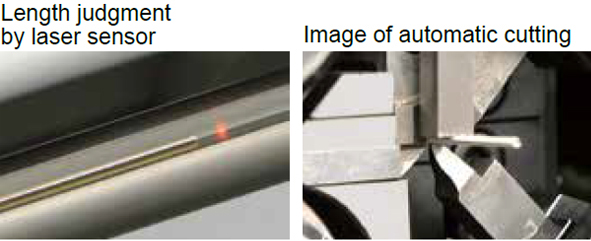

Compared with the conventional coiling production method, the automatic cutting ability structure after coiling makes continuous production of coils. This saves about 90% of labor in one day's work. In addition, the yield is improved because there is no extra waste material generated during production.

- 3. Supports high-speed production

-

This machine automatically adjusts the amount of wire drawn out and feeds it into the machine. As a result, in additional to stable high-quality processing, the production speed increases about 3 times(According to our research) compared to conventional coiling with the core production method.

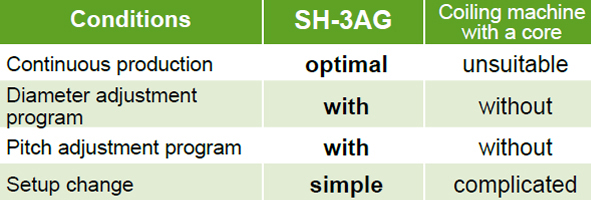

- 4. Comparison with SH-3AG and a coiling machine with a core

-

Movies

MEC SH-3AG ø0.18 mm

Specifications

- Systems:

-

- SH-3AG: Dual-point coiling machine

- TY-10A: Automatic wire supply stand with tension controlled

- Dedicated cut unit

- Options:

-

- Outer coil diameter measuring unit

- PR-2: Rotary discharge shooter

| Machine name | SH-3AG | |

|---|---|---|

| Wire diameter | ø0.08 ~ ø0.23 mm | |

| Outer coil diameter | ø10 mm | |

| Spring index | D/d 4 or more | |

| Feed axis | 0.0001 mm | |

| Max feed speed | 85 m/min | |

| Cut axis* | 0.001° | |

| Torsion attach axis* | 0.001° | |

| 1st point axis* | 0.0001 mm | |

| 2nd point axis* | 0.001° | |

| Initial tension axis* | 0.001° | |

| Arbor axis* | 0.001 mm | |

| Solenoid valves | 8 pcs | |

| Max air pressure | 0.5 MPa | |

| Power source | 3-phase, AC 200V, 15A | |

| Net weight | 380 kg | |

| Control device | Windows | |

| Display | 15.6” Full HD touch screen | |

| External memory | USB Thumb drive | |

| Temperature | 5 ~ 40°C | |

*Resolution: Program input unit, which does not represent accuracy.

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for non-Japanese specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us