WANMS Pressure Waveform Analysis Software

Pressure waveform analysis software

Wave Analysis Network Monitor System

Simply connected with a press with a load monitor, WANMS can easily sample and analyze the waveforms generated during processing.

WANMS also remotely monitors current operating status in real time.

WANMS Pressure waveform analysis software

Features

- 1. Management of stamping pressure from servo to general-purpose presses

- The peak pressure during processing is monitored in real time with a network connection with a servo press or general-purpose crank press equipped with a load monitor.

-

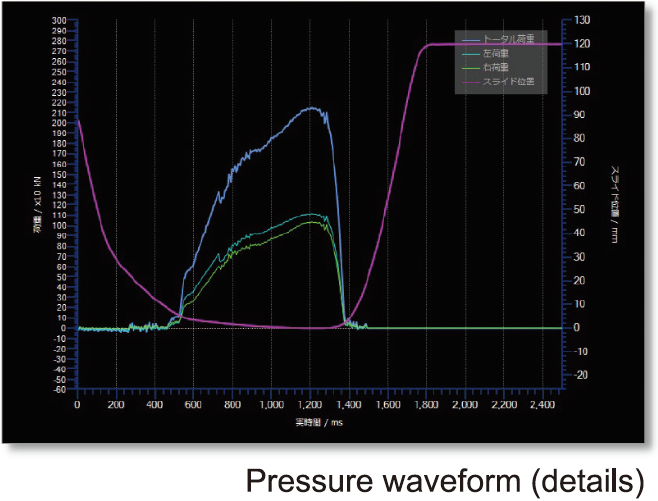

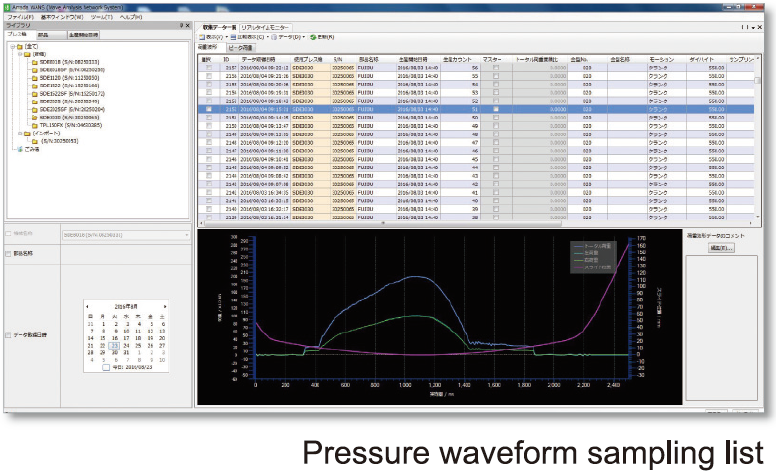

- 2. Sampling and analysis of waveform data

- The individual or collective pressure applied on the left and right sides of the frame is displayed in both a graph and numerical data.

Usable as an analysis tool of waveform data sampled, such as zoom-in/out and moving of waveforms, simultaneous display, comparison/overlapping display, and correlation of two waveforms, and so on.

When connected with a servo press, also capable of sampling torque waveform data and displaying energy values. -

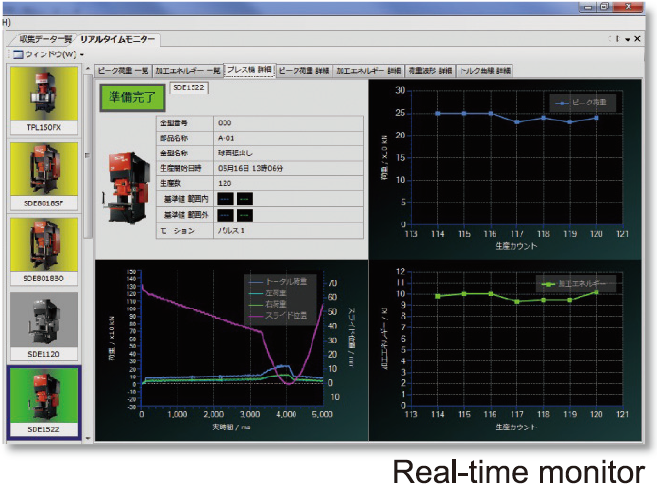

- 3. Monitoring of processing contents and peak pressure

- The presses connected to the network are remotely monitored in real time.

The name of a part being stamped, number of shots, press operating status, etc. are displayed in an easy-to-understand manner.

Deviation from the standard pressure or energy value range set for each part is shown as a change in a graph. -

Specifications

| Software | APINES |

|---|---|

| OS *1 | Windows 10 Pro (32bit/64bit) |

| CPU | Operating frequency: 1.5 GHz or higher |

| Main memory | 2 GB or more*2 |

| HDD | Approx. 1.5 GB necessary upon installing the software. Will need to be increased for saving the data automatically sampled. |

| Screen | Display resolution: 1024 x 768 or more, 32-bit colors |

| Network | Network adapter (1 port) supporting TCP/IP protocol*3 |

| Other hardware configurations | To conform to the operating conditions of the OS in use |

*1 Operability confirmed OS's. For other editions or languages, consult us. Operation in a virtualized environment will not be covered by warranty.

*2 4 GB at maximum for 32-bit OS. To use a main memory over 4 GB, use a 64-bit OS.

*3 For connecting a press with the server PC, wired connection with a LAN cable is recommended. Connection in a wireless LAN environment is not recommended.

Functions list

| WANMS |

SDE, SDEW and SWE Series |

TP/TPL-FX Series |

|---|---|---|

|

Maximum number of connectable presses |

Max 65,535 *4 |

Max 65,535 *4 |

|

Automatic sampling of waveform data |

Pressure waveform, peak pressure, stamping energy |

Pressure waveform, peak pressure |

|

Observation and analysis of various waveform data |

Zoom-in/out and parallel moving of waveforms, comparison of two waveforms, evaluation of production status using statistics graph |

Zoom-in/out and parallel moving of waveforms, comparison of two waveforms, evaluation of production status using statistics graph |

|

Various report output |

Pressure waveform, peak pressure, process energy, motion |

Pressure waveform, peak pressure |

|

Others |

CSV file export (pressure waveform, peak pressure, process energy) Waveform data import |

CSV file export (pressure waveform, peak pressure) Waveform data import |

*4 Depending on when the press was shipped from our factory, updating the firmware may be necessary. Also, the system functions may be limited with a press with special specifications. For details, consult us.

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for non-Japanese specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us