APINES Visualization Software of Press Shop

Visualization software of press shop

Amada Press machine Information NEtwork System

You can monitor operation status of press machines easily only by connecting a LAN cable to an APINES server.

Operation and production history are accumulated automatically in the data base by the APINES server.

You can check status of remote machines simply with browser software through an internet connection.

APINES Visualization software of press shop

Features

- 1. Central control and monitoring of press machines connected to network

- Operation status of machines are collected and a data base is created in real time to realize visualization of manufacturing plant with a browser software. When a wireless LAN is utilized, you can make monitoring with tablet terminals.

-

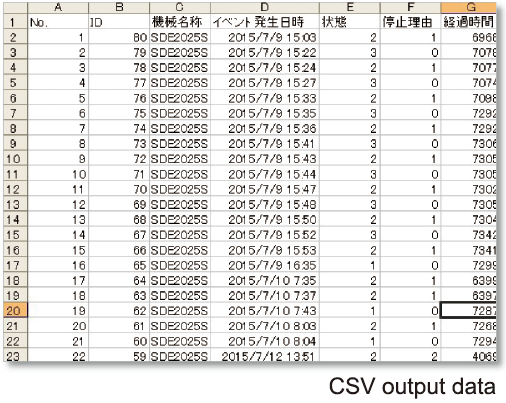

- 2. Collection of history data such as machine, part, worker, date and time

- Collected operation status of machines can be presented in a time chart and other detailed indication in real time. Operation history and production history can be extracted in the status of machine, part, worker, etc. and presented in a CSV data file.

By setting stopping reasons, Net working ratio and stop factors of each machine can be analyzed. Using various output data, you can prepare required forms such as work reports, production control data, etc. for production control. -

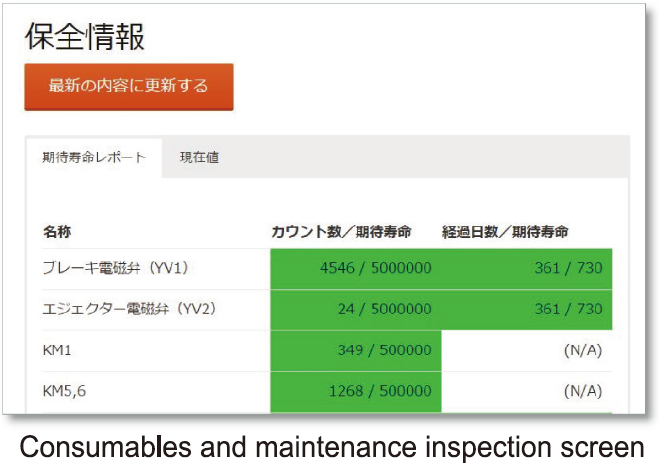

- 3. Service life of consumables and maintenance and inspection information are alerted

- Service life of oil and consumables are controlled and replacement time is notified. Alarm history is stored, which can be utilized for maintenance and inspection of machines.

-

- 4. Backup information about motions, dies, products, etc.

- Parameters and setting details of each machine are backed up and restored anytime.

Minimize down time such as unexpected loss of data that leads to delay in production.

Data of workers, stopping reasons and defect reasons can be transmitted and registered to machines. Also, as image data can be registered to machines, production error is prevented. -

Specifications

| Software | APINES |

|---|---|

| OS *1 | Windows 10 Pro (32bit/64bit) |

| CPU | Operating frequency: 1.5 GHz or higher |

| Main memory | 2 GB or more *2 |

| HDD | Approx. 1.5 GB necessary upon installing the software. Will need to be increased for saving the data automatically sampled. |

| Screen | Display resolution: 1024 x 768 or more, 32-bit colors |

| Network | Network adapter (1 port) supporting TCP/IP protocol*3 |

| Other hardware configurations | To conform to the operating conditions of the OS in use |

*1 Operability confirmed OS's. For other editions or languages, consult us. Operation in a virtualized environment will not be covered by warranty.

*2 4 GB at maximum for 32-bit OS. To use a main memory over 4 GB, use a 64-bit OS.

*3 For connecting a press with the server PC, wired connection with a LAN cable is recommended. Connection in a wireless LAN environment is not recommended.

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for non-Japanese specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us