DPG-150

Digital profile grinder

Industry's first profile grinder with a measurable digital projector

Enables High-Precision Profile Grinding by Any operator! New Digital Measurement Dramatically Improves Part Processing and Productivity.

Over 80 years of profile grinder machine history, the projector was digitized at last.

The conventional projector has evolved into a "state of the art" digital projector equipped with a digital measurement function. The "work to see" measurement process for the operator has turned "automatic".

The automatized measurement and correction program brings a fully automatic working environment that achieves high-precision grinding and greater productivity.

This new era of profile grinder was created through the prusuit and exploration of the possibilities of digitization.

Features

- ■ Features(1) : Industry's first projector ※Patent pending

-

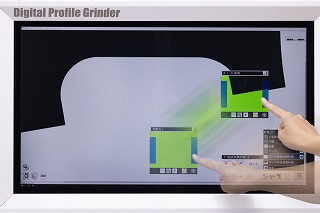

- Displays detailed shapes indispensable for high-precision processing on a 4K monitor.

- A new and Improved lower view point of the monitor makes it more ergonomically friendly for part measurement.

- All commands required for measurement can be selected from in the projector display, it makes immediate digital measurement possible.

- Wide monitor 690 mm in width and 370 mm in height, with a maximum magnification of 110.

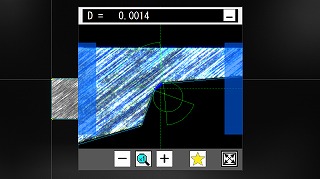

- A magnified loupe displays images enlarged by up to 400 times, moves freely inside the projector, and easily measures details.

- ■ Features(2) : Simple measurement and general-purpose measurement of work shape

-

- Simple measurement function that eliminates the need for visual recognition by operator.

- The edge detection function enables the measurement of R, taper angle, and pitch.

- General-purpose work shape measurement enables grinding shape and error measurement.

- Part tolerance errors will be displayed through the overlapping of the CAD shape over the workpiece image all time, positioning the magnification loupe will allow measuring of any feature of the part and displaying result.

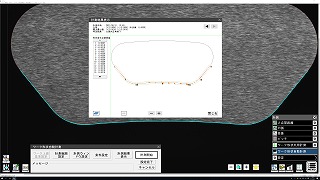

- ■ Features(3) : Automatic work shape measurement

-

- Automatically measure the shape between the starting and ending points instructed during the preparation of the machining program.

- Measured results are indicated as errors and differences at each intersection.

- "Overlay display" shows "differential display" on the projected work image is a feature. Grinding results can be easily visualized.

- Measured results can be output externally.

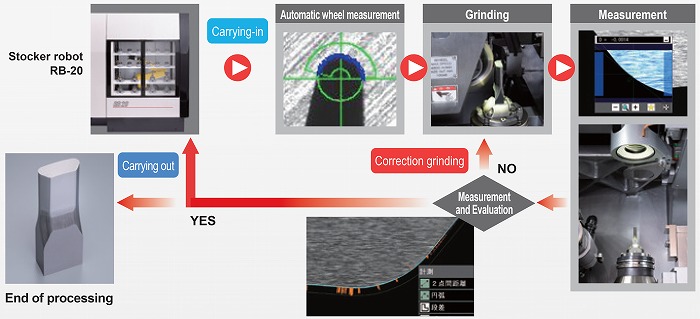

- ■ Features(4) : Automatic measurement/Compensation processing/Wheel measurement

-

- Adapting the latest features and benefits from a culmination of decades of image processing technology and innovative achievements.

- Automatically runs measurement and correction after grinding. Grinding to the target tolerance is performed automatically.

- Performing automatic grinding within the same specified tolerances by operators of any skill level.

- Adding ATC/AWC Robotics will allow for continuous grinding of workpieces with multiple wheel changes to process parts from rough to finish for greater productivit

Specifications

| Model |

DPG-150 |

|||||

|

Half cover spec. |

Full cover spec. | Full cover + Robot spec. | ||||

| Table | Working surface (L x W)(mm) |

400×250 |

||||

| Travel (mm) | Traverse feed (Z-axis) |

300 |

||||

| Cross feed (V-axis) |

150 |

|||||

| Vertical feed(A-axis) |

125 |

|||||

| Feed speed (mm/min) | Rapid traverse (G0) |

2000 |

||||

| Grinding feed (G01) |

0.1~1000 |

|||||

| Reciprocation | Reciprocating slide stroke (mm) |

0~155 |

||||

| Reciprocation speed (min-1) |

30~400※1 |

|||||

| Wheel head | Travel (mm) | Traverse feed (X-axis) |

200 |

|||

| Cross feed (Y-axis) |

150 |

|||||

| Relief angle (°) | Radial direction of wheel |

-2~20 |

||||

| Axial direction of wheel |

±15 |

|||||

| Swivel slide swiveling angle (°) |

±15 |

|||||

| Projector |

690×370 (32in) |

|||||

| Magnification | Normal/High magnification loupes |

Max 110/400 |

||||

| LED illumination | Lower part (transmission) | Digital dimming | ||||

| Upper part (reflection) |

Digital dimming |

|||||

| Spindle |

Wheel size |

High-speed type specs |

Middle diameter:65~100×4~6×22.23 |

ATC Middle diameter:75~100×4~6×22.23 | ||

| Low-speed type specs |

Major diameter:120~180×3~10×31.75 |

─ | ||||

| Wheel spindle speed (min-1) | High-speed type specs |

2000~20000 (TC-20)※2 |

2000~20000 | |||

| Low-speed type specs |

1000~6000 (TS-6)※2 |

─ | ||||

| Machine dimensions (W×L×H)(mm) |

3000×3000×2000 |

3000×3000×2000 | 3290×3330×2000 | |||

| Mass of machine (kg) |

4500 |

5000 | 5000+500 | |||

※1 There is a limitation depending on vertical travel distance.

※2 Selection specifications.

Specifications, appearance and equipment are subject to change without notice by reason of improvement. This products is for Japan domestic market.

Contact Us

Contact for repair/recovery of AMADA MACHINERY products and our corporate activities.

Contact Us