ML-2650B ML-2651B

Well-equipped features and high-power enable high-speed and high-quality welding!

*ML-2650B and ML-2651B will be discontinued.

Please ask us about new model.

Contact form

Plaese click here to get the manual

- Welding with a few heat-affected area can be done due to that laser welding is "contactless" welding.

- Real-time Power Feedback feature ensures stable welding under optimum weld conditions.

- Employing an optical fiber makes its automation easy.

- High power oscillator enables high speed seam welding.

- Up to four energy sharing.

- Controller is detachable.

Standard Features

Features

What you set is what you get

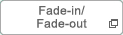

Thanks to the output power feedback system, the exact laser output power can be obtained just as you set on the unit. In addition, the output power and output waveform are displayed on the controller's monitor.

Automatic correction of the pumping energy

Since the energy fed to the lamp is automatically corrected, there is no need for bothersome adjustment, even thought the laser output would be fluctuated caused by some reasons, such as lamp's deterioration and thermal lens effect on the YAG rod.

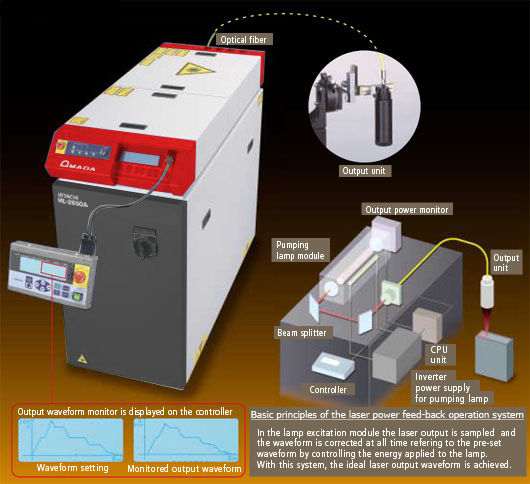

The configured output power with the waveform will be provided just as set from the first shot

Since the desired laser output in the right waveform is applied to the work from the first shot, there is no need for "warming-up" shots before the actual welding.

- ■ Real-time Power Feedback Feature

- ■ High efficiency delivery balance without power loss

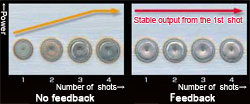

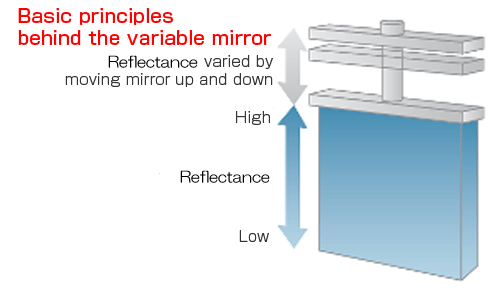

- The newly adopted variable mirror eliminates the laser power loss and brings balance of deliveries which is resulted in a significant improvement in beam splitting precision.

Maximum of up to 4 deliveries of optical fibers can be connected (Chargeable option) either on the top side or backside of the laser unit. -

- ■ Interface designed for workability

-

Welding initiated by an external start signal can be modified with the local controller during operation. Since the controller can be detached from the main unit, it can be operated at your hand. The start response time can be set in five different times within 0.1 to 16.0ms. Also, conditions can be switched to another during the response time.

-

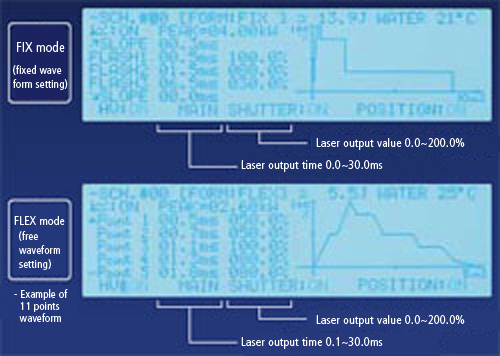

- ■ Advanced waveform control functions

-

With the waveform control functions there are two modes, Fix mode which is based on a 3-step waveforms, and Flex mode where you can set up to 20 inflexion points to create complex waveforms. Since the optimum welding schedules can be set depending on the various materials, blow holes and cracks can be avoided and the welding quality will be improved.

-

- ■ High-speed, high-quality welding

-

High-speed seam welding is possible with high repetition rate of up to 500pps. Also, power feedback control and waveform control functions enable high-quality welding for a variety of work-pieces.

-

- ■ Operation section controller

-

The controller is detachable from the main unit and can be operated by hand.

Large color touchscreen is equipped for ML-2600 series. - ■ Supports factory automation easily

-

These devices are equipped with a wealth of input/output terminals (signals), so they can be easily connected to automatic equipment.

- ■ Optical fiber delivery system

-

A maximum of four branches are possible, including energy sharing and time sharing. (Optional)

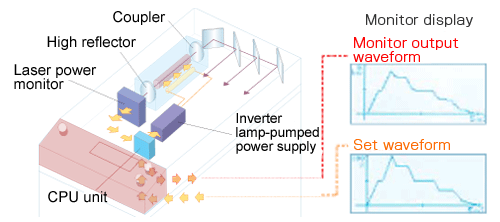

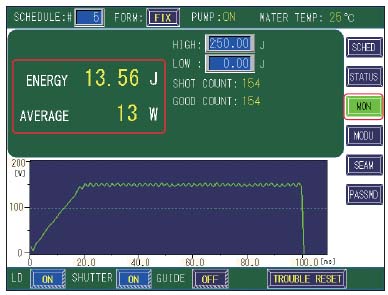

Real-time Power Feedback Control

The laser output in the lamp-pumped module is monitored in real time. The monitored laser output is compared with the set waveform and power is fed back in real time, varying the energy input to the lamp to reproduce the set waveform and obtain the ideal laser output waveform.

Variable mirrors

These mirrors eliminate laser power loss and improve branch balance.

Waveform control

Equipped with a "fixed mode" that features three-level waveforms, and a "flex mode" to provide more complex waveforms.

Power monitor

Laser energy (J) and average power (W) are monitored to detect abnormalities.

Controller

The controller can be detached from the main unit to operate at your hand.

External communications

Configuration of parameters and monitoring of performance can be carried out from a separate location.

- Type: RS-485 compliant, asynchronous, full duplex

- Data speed: 9600, 19200, 38400 bps

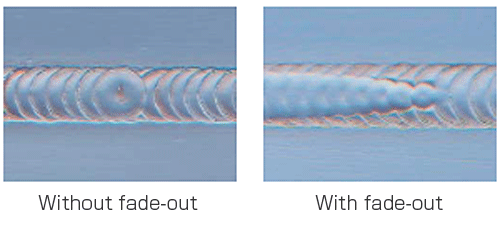

Fade-in/Fade-out

This feature avoids marks at the end of seam welding and provides a beautiful finish even for overlapping circumference seam welding sections.

Production Samples

Cigarette lighter

Gimbals

Optic connector

Motor core

Transformer core

Transformer core

Titanous body

Discharge valve

Motor

Lithium-ion battery

Specifications

| Model | ML-2650B *scheduled to be discontinued | ML-2651B *scheduled to be discontinued | ||||

| Oscillation wavelength | 1,064nm | |||||

| Maximum average power | 600W | 500W | ||||

| Maximum output energy | 100 J/P (Pulse width 10ms) | 80 J/P (Pulse width 10ms) | ||||

| Pulse width | Standard: 0.3 to 100.0 ms (0.1 ms steps) Fine setting: 0.25 to 5.00 ms (0.05 ms steps) |

|||||

| Pulse repetition | 1 to 500pps | |||||

| Fiber optic delivery | Up to 4 deliveries of laser output are available including powersharing and timesharing. (optional) | |||||

| External datacom | RS-485 | |||||

| Power requirements | 3-phase, 200, 380, 400 V AC±10%, 50/60Hz 3-phase, 220 V AC+10%-15%, 60Hz(Tap switching) |

|||||

| Cooler | Heat exchange method | Water - Water | ||||

| Required city water | Pressure: 294kPa (3kgf/cm²) maximum | |||||

| Water temperature: 5° to 35°C | ||||||

| Flow rate: 25 litter/min at 25°C 55 litter/min at 32°C |

||||||

| Differential pressure: 98 to 294kPa (1 to 3kgf/cm²) | ||||||

| Inner diameter of hose | Φ19mm | |||||

| <Note> | When chiller is employed, cooling capability of 23.5kW(20160 kcal/h) is required for the chiller cooler maximum | |||||

| Dimensions | 550(W) X 1,780(D) X 1,200(H)mm | |||||

| Weight | 540kg | |||||

*Specifications subject to change without notice.

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support