CTS-900NT

Network NC Tapping Machine

Rapidly improve operating efficiencies (shortening of processing time and reduction of setup)

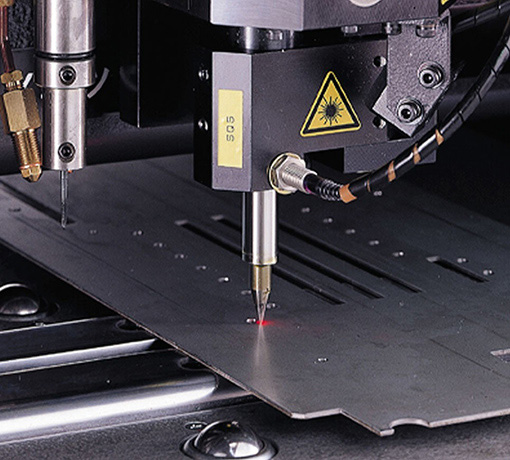

Revolutionary tapping machine that has automated tapping work and enabled connection with multiple machines such as NCT and laser machine.

The centralized data management enables speedy information retrieval, and at the same time maximizes the strengths of AMNC/PC, automatically creating programs and optimizing processing path.

Features

- ■ Feature (1) : Automatic program creation

- Reduction of internal setup man-hours

- Preventing forgetting taps and reducing wasteful inspection man-hours

- ■ Feature (2) : Optimization of processing path

- Automatic programming of efficient processing path

- ■ Feature (3) : Data management and utilization

- Management of processing history essential to prevent mistakes

- Lubrication interval can be set according to the product.

- ■ Feature (4) : Newly developed "4-axis tapper”

- One-touch coupler enabling quick tap replacement

- Significant increase in processing axis speed

- Supports semi-dry processing

Production Samples

Specifications

|

Maximum axis travel |

Sheet thickness |

Material |

Positioning accuracy |

Tapping accuracy |

|

|---|---|---|---|---|---|

|

CTS-900NT |

0~2700×0~1100 |

0.8~4.5 |

SPCC/SPHC/SUS/AL |

±0.15 |

JIS Class 2 |

Specifications, appearance and equipment are subject to change without notice by reason of improvement.

This products is for Japan domestic market.

Contact Us

Contact for repair/recovery of AMADA MACHINERY products and our corporate activities.

Contact Us