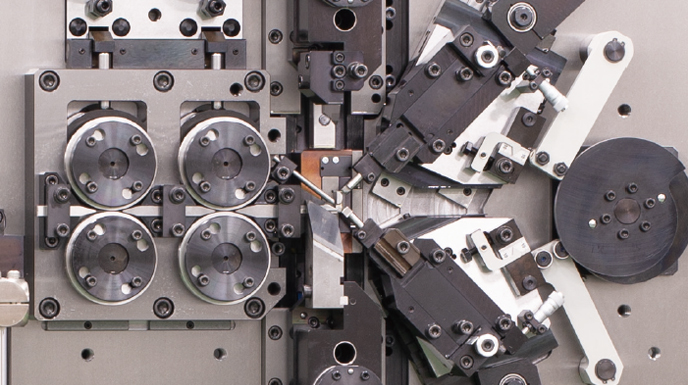

WH-26A (Dual-point、ø0.6 ~ ø2.6 mm)

8-Axis CNC Dual-Point Coiling Machine

WH-26A achieves high-speed production, high-precision coiling, and reduction of setup time.

It can process outer coil diameters up to ø70 mm.

The coil program, equipped with a pitch diagram, allows the user to easily create programs for multiple shapes.

Features

- 1. 8-axis control with an emphasis on operability and quality improvement, due to the introduction of a dual feed roller

-

- The WH-26A supports various shapes with the standard features of 8-axis control: cut, wedge-pitch, push-pitch, point, auxiliary point, center-cam, and arbor front and arbor back.

- The rotary or straight cuts and the wedge-pitch can be switched by simply moving the eccentric pin.

- You can switch programming between right- and left-hand coiling without replacing the heavy slide.

- The WH-26A is equipped with cut, wedge-pitch, and arbor functions on the center slide. As a result, it only needs to adjust the alignment of the cut tool once regardless of the coil diameter.

- The introduction of the dual feed roller reduces the load of feed pressure applied to the wire.

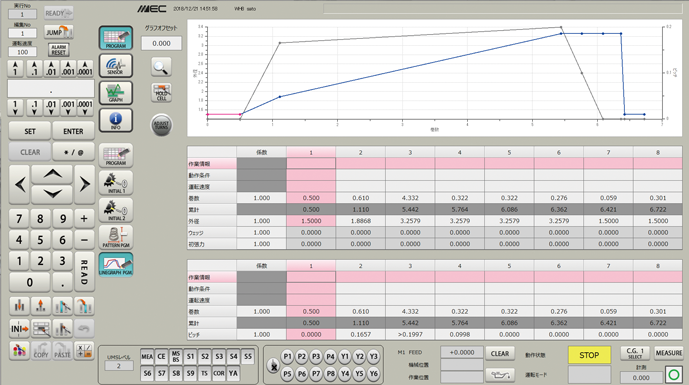

- 2. Improved operability with the MNO2 (MEC New Operation 2) programming software

-

- The MEC original spring program MNO2 easily organizes important statistics about the machine, including program flow, operating status of each axis, inputs/outputs, jump, etc., as with our other spring machines.

- The program editing function has greatly evolved, and the navigation system function and touch screen make it easier to create programs and shorten the setup time.

- The program for number of coils allows change of the feed, pitch, outer coil diameter, initial tension and wedge on the evolved pitch diagram screen, making it easier to adjust the basic coils.

- The automatic function of coil length correction is based on the capacitance length measurement method. The multi-functional production management system gives easy-to-control production.

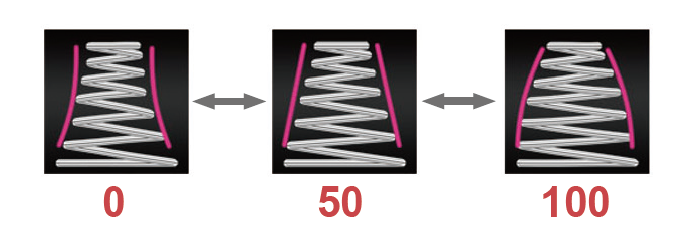

- 3. Taper Synchronization Constant

-

Enables the taper tilt to be managed with a value from 0 to 100. Suitable for load adjustment in addition to shape adjustment, as fine adjustment can be performed in 100 levels.

- 4. Support for IOT

- The operating status of machine can be monitored through mobile phones or computers, and regular maintenance with preventive maintenance functions can contribute to improved production efficiency.

- 5. Optional equipment

- A slip sensor that detects the slip of the wire during coiling can be selected as an option.

Movies

Specifications

| Machine name | WH-26A | |

|---|---|---|

| Wire diameter | ø0.6 ~ ø2.6 mm | |

| Outer coil diameter | ø70 mm | |

| Index | D/d 4 or more | |

| Feed axis* | 0.0001 mm | |

| Max feed speed | 200 m/min | |

| Cut axis* | 0.001° | |

| Wedge-pitch axis* | 0.001° | |

| Push-pitch axis* | 0.0001 mm | |

| Point axis* (auxiliary) | 0.0001 mm | |

| Center-cam axis* | 0.0001 mm | |

| Arbor front/back* | 0.0001 mm | |

| Solenoid valves | 4 pcs (Max 8 pcs) | |

| Max air pressure | 0.5 MPa | |

| Power source | 3-phase, AC 200V, 20A | |

| Net weight | 1,100kg | |

| Control device | Windows | |

| Software | MNO2 | |

| Display | 15.6” Full HD touch screen | |

| External memory | USB Thumb drive | |

| Temperature | 5 ~ 40°C | |

*Resolution: Program input unit, which does not represent accuracy.

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for non-Japanese specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us