AMADA PRESS SYSTEM

Spring Machines

Torsion Spring Machines

NEW

DZ-3A (ø0.04 ~ ø0.3 mm)

15-Axis CNC Coiling and Torsion Machine for Ultra-Fine Wire

The fusion of high-speed, high-precision coiling, and freely formed torsion processing expands into new application ranges within the field of ultra-fine wire.

Features

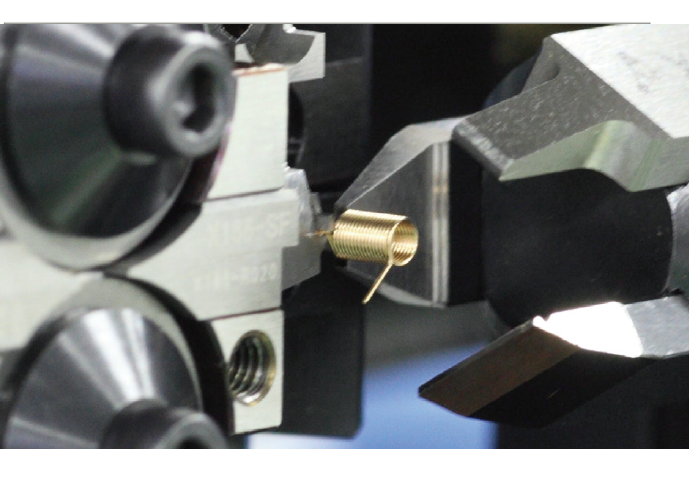

- 1. Increasing production possibilities by combining high-speed, high-precision coiling and bending processing

- This machine can process coils equivalent to standard coil machines and allows flexible bending with three 3D slides. This gives the operator and endless amount of processing possibilities, which they could have never imagined before.

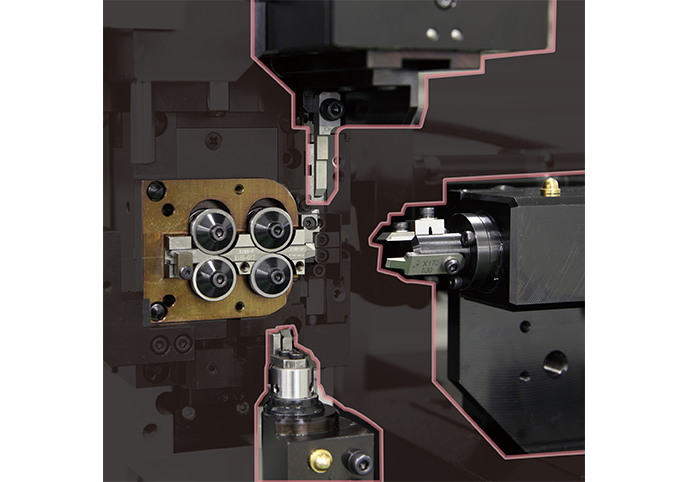

- 2. 3D slides with versatile modular design capability

- Each 3D slide can be equipped with modular units such as tool changers or rotary servo motors.

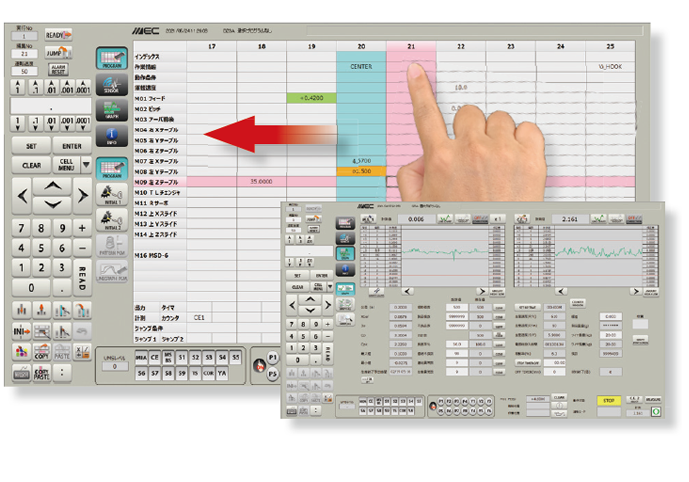

- 3. Improved operability with the MNO2 (MEC New Operation 2) programming software

-

- The MEC original MNO2 software easily organizes important statistics about the machine, including program flow, operating status of each axis, inputs/outputs, jump, etc., as with our other spring machines.

- Greatly improved operability, with the easy-to-use navigation system and the touch screen, makes it easy to create programs and shortens setup time.

- The motor sensor system makes every slide a sensor. It is possible to measure the presence/absence judgment with a touch sensor, coiling angle, free length, etc. in 0.001 mm units. The measurement results are displayed in tables and graphs, and easy correction control for each axis is possible.

- Highly efficient production is supported by a versatile production management and data collection functions.

- 4. Support for IOT

- The operating status of machine can be monitored through mobile phones or computers, and regular maintenance with preventive maintenance functions can contribute to improved production efficiency.

Movies

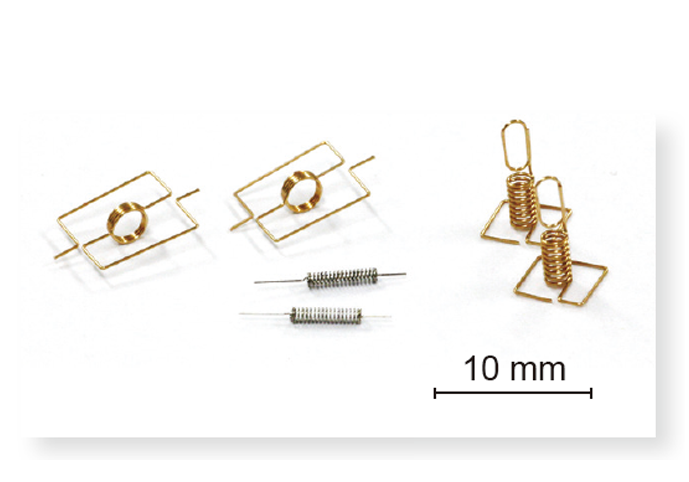

Production Samples

Specifications

| Machine name | DZ-3A |

|---|---|

| Wire diameter *1 | ø0.04 ~ ø0.3 mm |

| Outer coil diameter | ø8 mm |

| Index | D/d 3.5 or more |

| Feed axis *2 | 0.0001 mm |

| Pitch axis *2 | 0.0001 mm |

| Arbor front/back axis *2 | 0.001° |

| R/L3D table axis *2 | 0.0001 mm |

| Upper 3D slide axis *2 | 0.001 mm |

| Tool changer axis *2 | 0.001° |

| R-servo axis *2 | 0.001° |

| Solenoid valves | 4 pcs (Max 8 pcs) |

| Max air pressure | 0.5 MPa |

| Power source | 3-phase, AC 200V, 15A |

| Net weight | 860 kg |

| Control device | Windows |

| Software | MNO2 |

| Display | 15.6” Full HD touch screen |

| External memory | USB Thumb drive |

| Temperature | 5 ~ 40°C |

*1 The option holder for ultra-fine wire can handle wire diameters from ø0.02 ~ ø0.1 mm.

*2 Resolution: Program input unit, which does not represent accuracy.

Related products

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for non-Japanese specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us