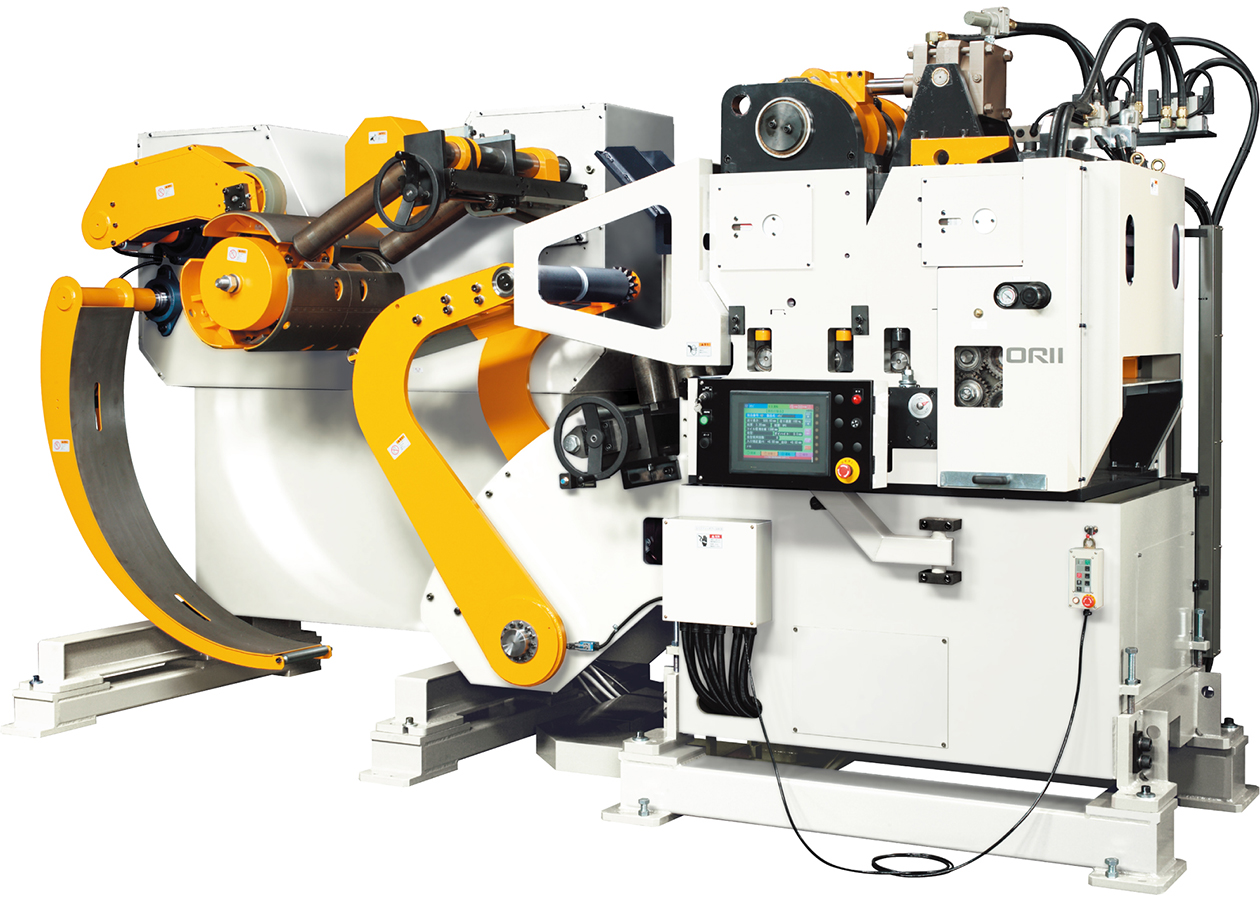

LCC PM2 Series (w: 70 ~ 1300 mm, t: 0.8 ~ 9.0 mm)

This series handles material from 70mm to 1,300mm wide and up to 9.0mm thick.

Several advancements have been made on this model.

The number of work rolls has been increased from 5 to 9, resulting in a greater degree of flatness, and a straightener port opening mechanism has been added, allowing for improved maintenance of this heavy-duty machinery.

Features

- ■ Features(1) : 9 Work Rolls

-

The PM2 represents a new standard in feeding technology, with the ability to handle plate up to 9.0mm(0.35″) thick. Combining the power of the heavy-duty PM unit with the straightening performance of 9 work rolls (5 upper and 4 lower), the PM2 gives material a high degree of flatness.

- ■ Features(2) : Easy Access to Work Rolls

-

The work rolls on the PM2 can be opened to a maximum of 20 degrees, making roll cleaning much easier. The machine was designed to allow easy access to the inside structure for improved maintenance.

- ■ Features(3) : Electronic Straightening Adjustment

-

The PM2 features an automatic system for straightening adjustment, unlike precious models which adjusted straightening with manual wheels. The new electronic straightening system is easy to use and allows for faster changeover.

- ■ Features(4) : TP-CCS Controller

-

A wide variety of information needed for planning, operation, maintenance, etc., is uniformly controlled under the base mode of “Settings, Planning, Operation, and Maintenance”. Equipped with various new operations, it is a complete operation system that responds to diversification and sophistication of merchandise and reduction of work time.

Specifications

| Model | LCC06PM2 | LCC08PM2 | LCC10PM2 | LCC13PM2 | ||

|---|---|---|---|---|---|---|

| Stock Thickness | mm | 0.8~9.0 | 0.8~9.0 | 0.8~9.0 | 0.8~9.0 | |

| Stock Width | mm | 70~600 | 70~800 | 70~1,000 | 70~1,300 | |

| MAX.Coil Mass | kg | 3,000 | 5,000 | 7,000 | 7,000 | 7,000 |

| MAX.Coil O.D. | mm | 1,400 | 1,400 | 1,400 | 1,400 | |

| Coil I.D. | mm | 508 | 508 | 508 | 508 | |

| Feed Length(※) | mm | *1 ~500 | *1 ~500 | *1 ~500 | *1 ~500 | |

| MAX.Line Speed | m/min | 22 | 22 | 22 | 22 | |

| Work Roll Number | ― | upper5 / lower4 | upper5 / lower4 | upper5 / lower4 | upper5 / lower4 | |

| Main Motor | kW | AC22.0 | AC22.0 | AC22.0 | AC22.0 | |

| Mandrel Expansion | ― | pneumatic | pneumatic | hydraulic | hydraulic | hydraulic |

| Reel Motor | kW | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 |

| Power | V | 200/220 | 200/220 | 200/220 | 200/220 | |

| Operating Air | MPa | 0.49 | 0.49 | 0.49 | 0.49 | |

*1:In case Feeding Length exceeding Specification, MASTER CONTROL Function (Option) must be provided.

Straightening Performance

| Model | LCC06PM2 | LCC08PM2 | LCC10PM2 | LCC13PM3 | |

|---|---|---|---|---|---|

| Roll length (mm) | 620 | 820 | 1,020 | 1,320 | |

| Stock Thickness (mm) | 0.8~2.3 | 600 | 800 | 1,000 | 1,300 |

| 2.5 | |||||

| 2.8 | |||||

| 3.2 | |||||

| 4.0 | 1,010 | ||||

| 4.5 | 800 | 800 | |||

| 5.0 | 640 | 640 | 640 | ||

| 6.0 | 450 | 450 | 450 | 450 | |

| 7.0 | 330 | 330 | 330 | 330 | |

| 8.0 | 250 | 250 | 250 | 250 | |

| 9.0 | 200 | 200 | 200 | 200 | |

※The unit in the above table is represented in millimeters.

※The above figures are for the material having yield strength of 245N/mm2 and feed speed in the situation indicated is 0.687m/s.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us