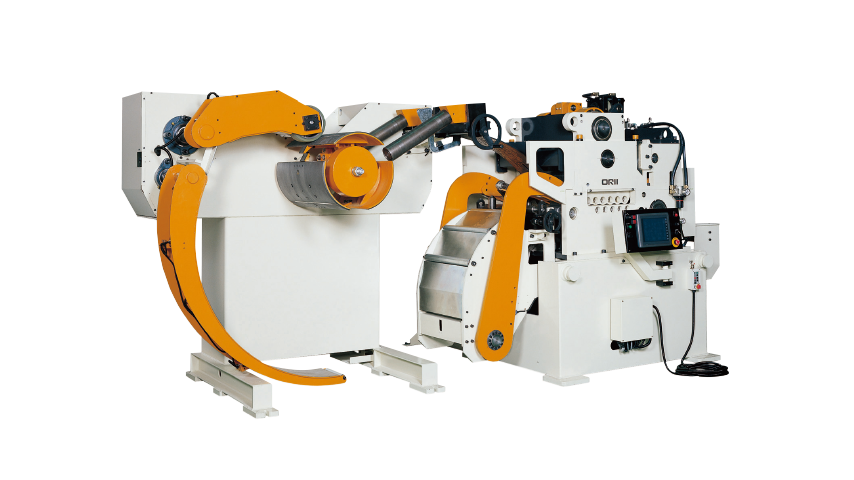

LCC HL Series (w: 70 ~ 1300 mm, t: 0.6 ~ 6.0 mm)

This series handles material from 600mm to 1,300mm wide and up to 6.0mm thick.

The 11 work rolls enable an extraordinary level of flatness for materials.

Features

- ■ Features(1) : High Degree of Flatness

-

Combining the power of the heavy duty HL unit with the straightening performance of 11 work rolls (6 upper and 5 lower), the HL unit gives material a high degree of flatness to materials up to 6.0mm thick.

- ■ Features(2) : Easy Access to Work Rolls

-

The work rolls on the HL can be opened to a maximum of 20 degree, making roll cleaning much easier. The machine was designed to allow easy access to the inside structure for improved maintenance.

- ■ Features(3) : Work Rolls Drive System

-

■Side Gear System

The feed roll is equipped with gears that drive each roll, making the lower work rolls run.■All Rolls Driven with Universal Joint System

This system makes all rolls through universal joints which connect each roll by a motor-driven parallel gear box. This system is especially recommended for both high tension materials and easy-to-slip materials.

- ■ Features(4) : TP-CCS Controller

-

A wide variety of information needed for planning, operation, maintenance, etc., is uniformly controlled under the base mode of “Settings, Planning, Operation, and Maintenance”. Equipped with various new operations, it is a complete operation system that responds to diversification and sophistication of merchandise and reduction of work time.

- ■ Features(5) : High torque / high rigidity

-

All rolls drive system (HLU model) * and frame rigidity improvement (four times higher than the conventional equipment) have enabled straightening of high-tensile steel plate.

* Refer to the work roll drive system

Specifications

| Model | 06HLS | 08HLS | 10HLS | 13HLS | 06HLU | 08HLU | 10HLU | 13HLU | |

|---|---|---|---|---|---|---|---|---|---|

| Stock Thickness | mm | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 |

| Stock Width | mm | 70~600 | 70~800 | 70~1,000 | 70~1,300 | 70~600 | 70~800 | 70~1,000 | 70~1,300 |

| MAX.Coil Mass | kg | 3,000 | 5,000 | 7,000 | 7,000 | 3,000 | 5,000 | 7,000 | 7,000 |

| MAX.Coil O.D. | mm | 1,400 | 1,400 | 1,400 | 1,400 | 1,400 | 1,400 | 1,400 | 1,400 |

| Coil I.D. | mm | 508 | 508 | 508 | 508 | 508 | 508 | 508 | 508 |

| Feed Length(※) | mm | ~500 | ~500 | ~500 | ~500 | ~500 | ~500 | ~500 | ~500 |

| MAX.Line Speed | m/min | ~22 | ~22 | ~22 | ~22 | ~22 | ~22 | ~22 | ~22 |

| Work Roll Number | ― | upper6 / lower5 | upper6 / lower5 | upper6 / lower5 | upper6 / lower5 | upper6 / lower5 | upper6 / lower5 | upper6 / lower5 | upper6 / lower5 |

| Main Motor | kW | AC11.0 | AC11.0 | AC11.0 | AC11.0 | AC30.0 | AC30.0 | AC30.0 | AC30.0 |

| Mandrel Expansion | ― | pneumatic | pneumatic | hydraulic | hydraulic | pneumatic | pneumatic | hydraulic | hydraulic |

| Reel Motor | kW | 2.2 | 2.2 | 3.7 | 3.7 | 2.2 | 2.2 | 3.7 | 3.7 |

| Power | V | 200/220 | 200/220 | 200/220 | 200/220 | 200/220 | 200/220 | 200/220 | 200/220 |

| Operating Air | MPa | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 |

※:In case Feeding Length exceeding Specification, MASTER CONTROL Function (Option) must be provided.

Straightening Performance

| Straightening Performance | Stock Width (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | 06HLS | 08HLS | 10HLS | 13HLS | 06HLU | 08HLU | 10HLU | 13HLU | |

| Stock Thickness (mm) |

0.8~2.3 | 600 | 800 | 1,000 | 1,300 | 600 | 800 | 1,000 | 1,300 |

| 2.8 | 933 | 933 | 941 | 941 | |||||

| 3.2 | 714 | 714 | 714 | 720 | 720 | 720 | |||

| 4.0 | 457 | 457 | 457 | 457 | 461 | 461 | 461 | 461 | |

| 4.5 | 361 | 361 | 361 | 361 | 364 | 364 | 364 | 364 | |

| 5.0 | 293 | 293 | 293 | 293 | 295 | 295 | 295 | 295 | |

| 6.0 | 203 | 203 | 203 | 203 | 205 | 205 | 205 | 205 | |

●The above figures are for the material having yield strength of 245N/mm2 max.

| Straightening Performance (For High tention materials) |

Stock Width (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | 06HLS | 08HLS | 10HLS | 13HLS | 06HLU | 08HLU | 10HLU | 13HLU | |

| Stock Thickness (mm) |

2.3 | 255 | 252 | 250 | 246 | 558 | 558 | 558 | 558 |

| 2.5 | 232 | 230 | 228 | 225 | 472 | 472 | 472 | 472 | |

| 2.8 | 205 | 203 | 202 | 199 | 376 | 376 | 376 | 376 | |

| 3.2 | 177 | 175 | 174 | 171 | 288 | 288 | 288 | 288 | |

| 4.0 | 138 | 136 | 135 | 133 | 184 | 184 | 184 | 184 | |

| 4.5 | 120 | 119 | 118 | 116 | 146 | 146 | 146 | 146 | |

| 5.0 | 106 | 105 | 104 | 103 | 118 | 118 | 118 | 118 | |

| 6.0 | 81 | 81 | 81 | 81 | 82 | 82 | 82 | 82 | |

●The above figures are for the material having yield strength of 600N/mm2 max.

※ Specifications are subject to change for improvement without notice.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us