LCC HR3 Series (w: 70 ~ 1300 mm, t: 0.6 ~ 6.0 mm) ECO Release

This series provides powers with the addition of intelligent functions to former multi-purpose capabilities.

Features

- ■ Features(1) : Eco Release

-

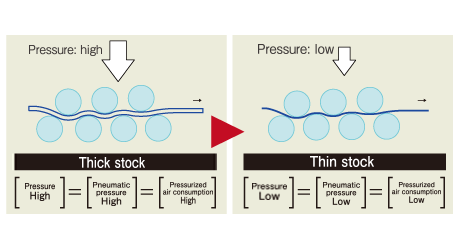

The energy-saving roll lift mechanism.

Auto-control of pneumatic cylinder pressure used in material straightening. This feature enables optimization according to stock thickness, achieving energy-savings of 30% to 50%.

- ■ Features(2) : Targeting Downsizing

-

Although the size has been compacted for a total length of only 3734mm(LCC04, 05, 06 HR3), this series handles material from 400 to 1300mm wide and up to 6.0mm thick and can be used for a wide variety of purposes. Highest priority is giving to human more working space, and the “HR3″series succeeds to the ORIIMEC’s policy.

- ■ Features(3) : TP-CCS Controller

-

A wide variety of information needed for planning, operation, maintenance, etc. is uniformly controlled under the base mode of “Settings, Planning, Operation, and Maintenance”. Equipped with various new operations, it is a complete operation system that responds to diversification and sophistication of merchandise and reduction of work time.

- ■ Features(4) : Large straightening roll adjustment wheel

-

Large straightening roll adjustment hand wheel have been adopted. Symbols are used for the indicators, improving repeatability and permitting easy numerical setting.

- ■ Features(5) : ORIIMEC's High Quality Design

-

High performance design results in excellent handling and operability with high precision and reliability realize by computer control. The high level of quality demanded of NC machines, in economic way, is achieved.

Specifications

| Model | 04HR3 | 05HR3 | 06HR3 | 08HR3 | 10HR3 | 13HR3 | |

|---|---|---|---|---|---|---|---|

| Stock Width | (mm) | 70~400 | 70~500 | 70~600 | 70~800 | 70~1,000 | 70~1,300 |

| Stock Thickness | (mm) | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 |

| MAX.Coil Mass | (kg) | ※1 3,000/5,000 | ※1 3,000/5,000 | ※1 3,000/5,000 | 5,000/7,000 | 7,000 | 7,000 |

| MAX.Coil O.D. | (mm) | 1,400 | 1,400 | 1,400 | 1,400 | 1,400 | 1,400 |

| Coil I.D. | (mm) | 508 | 508 | 508 | 508 | 508 | 508 |

| Feed Length(※) | (mm) | ※2 ~500 | ※2 ~500 | ※2 ~500 | ※2 ~500 | ※2 ~500 | ※2 ~500 |

| MAX.Line Speed | (m/分) | 22 | 22 | 22 | 22 | 22 | 22 |

| Work Roll Number | upper4 / lower3 | upper4 / lower3 | upper4 / lower3 | upper4 / lower3 | upper4 / lower3 | upper4 / lower3 | |

| Main Motor | (kW) | AC6.0 | AC6.0 | AC6.0 | AC6.0 | AC6.0 | AC6.0 |

| Mandrel Expansion | pneumatic | pneumatic | pneumatic | pneumatic/hydraulic | hydraulic | hydraulic | |

| Reel Motor | 2.2 | 2.2 | 2.2 | 2.2/3.7 | 3.7 | 3.7 | |

| Power | (V) | 200/220 | 200/220 | 200/220 | 200/220 | 200/220 | 200/220 |

| Operating Air | (MPa) | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 |

※1:3,000 is EAS, 5,000 is VAS type.

※2:In case Feeding Length exceeding Specification, MASTER CONTROL Function (Option) must be provided.

Straightening Performance

| Model | 04HR3 | 05HR3 | 06HR3 | 08HR3 | 10HR3 | 13HR3 | |

|---|---|---|---|---|---|---|---|

| Stock Thickness(mm) | 0.6~1.6 | 400 | 500 | 600 | 800 | 1,000 | 1,300 |

| 2.0 | |||||||

| 2.3 | |||||||

| 2.5 | 1,170 | ||||||

| 2.8 | 930 | 930 | |||||

| 3.2 | 710 | 710 | 710 | ||||

| 4.0 | 450 | 450 | 450 | 450 | 450 | ||

| 4.5 | 360 | 360 | 360 | 360 | 360 | 360 | |

| 5.0 | 290 | 290 | 290 | 290 | 290 | 290 | |

| 6.0 | 200 | 200 | 200 | 200 | 200 | 200 | |

※ The unit in the above table is represented in millimeters.

※ The above figures are for the material having yield strength of 245N/mm2max.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us