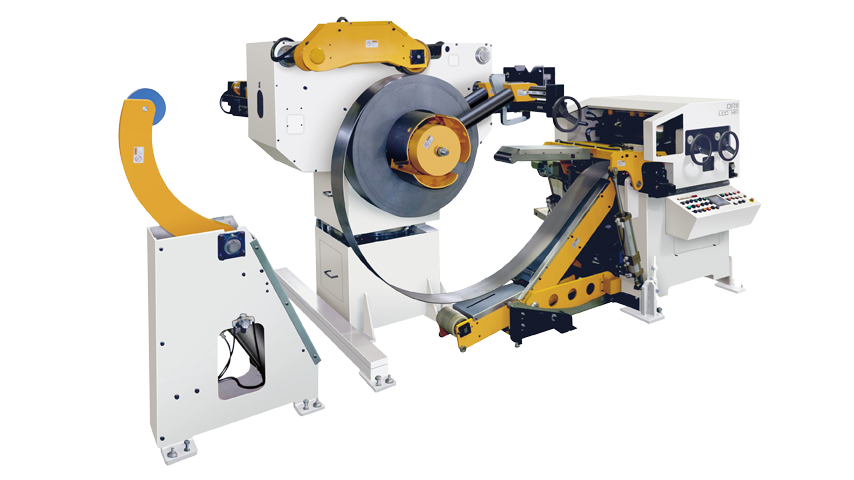

LCE HR3 Series (w: 70 ~ 600 mm, t: 0.6 ~ 6.0 mm) ECO Release

For the LCE HR3 series, simple button operations can make coil material threading and material loop formation automatic.

This is a state-of-the-art straightener feeder that achieves both improvements in work setups and a high level of economic performance. A wide range of specifications can be handled, including material widths of 100 to 600mm and sheet thicknesses of 1.0 to 6.0mm. Furthermore, the reduction of setup times has also been thoroughly pursued, through the addition of a double uncoiler type device ton the product lineup as part of a new series. These products will demonstrate their strength at all kinds of processing worksites.

Features

- ■ Features(1) : Reduction of setup times and improvement of workability and safety

-

Materials mounted on the uncoiler are automatically threaded up to the straightener exit side until a loop shape is formed, and this leads to shorter setup times. Furthermore, in order to carry out the smooth threading of materials, an auxiliary coil press for preventing coil bulges has been installed as a standard part of the equipment. Also, the pressing of coil material perimeters at four points prevents looseness at the time of coil insertion.

- ■ Features(2) : Improved ease of maintenance and economic performance

-

A mechanical system with the lower coil press has been newly developed and there has a switch from oil pressure to air with regard to the operation actuator. Thus, ease of maintenance and economic performance have been improved.

- ■ Features(3) : Adoption of PLC control

-

As a result of the PLC control system, it is possible to flexibly respond to the specifications of customers.

Movies

Specifications

| Model | 04HR3E | 04HR3V | 05HR3E | 05HR3V | 06HR3E | 06HR3V | ||

|---|---|---|---|---|---|---|---|---|

| Stock Width | mm | 100~400 | 100~400 | 100~500 | 100~500 | 100~600 | 100~600 | |

| Stock Thickness | Automatically Feed | mm | 1.0~6.0 | 1.0~6.0 | 1.0~6.0 | 1.0~6.0 | 1.0~6.0 | 1.0~6.0 |

| Manual Feed | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | 0.6~6.0 | ||

| MAX.Coil Mass | Single | kg | 3,000 | 5,000 | 3,000 | 5,000 | 3,000 | 5,000 |

| Double | 3,000×2 | 5,000×2 | 3,000×2 | 5,000×2 | 3,000×2 | 5,000×2 | ||

| MAX.Coil O.D. | mm | 1,400 | 1,400 | 1,400 | 1,400 | 1,400 | 1,400 | |

| Coil I.D. | mm | 508 | 508 | 508 | 508 | 508 | 508 | |

| Feed Length(※) | mm | ~500 | ~500 | ~500 | ~500 | ~500 | ~500 | |

| Work Roll Number | ― | upper4 / lower3 | upper4 / lower3 | upper4 / lower3 | upper4 / lower3 | upper4 / lower3 | upper4 / lower3 | |

| Mandrel Expansion | pneumatic | pneumatic | pneumatic | pneumatic | pneumatic | pneumatic | ||

| Power | V | 200/220 | 200/220 | 200/220 | 200/220 | 200/220 | 200/220 | |

| Operating Air | MPa | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 | |

(※):In case Feeding Length exceeding Specification, MASTER CONTROL Function (Option) must be provided.

Straightening Performance

| Stock Width (mm) | |||||||

|---|---|---|---|---|---|---|---|

| Model | 04HR3E | 04HR3V | 05HR3E | 05HR3V | 06HR3E | 06HR3V | |

| Stock Thickness (mm) |

0.6~1.6 | 400 | 400 | 500 | 500 | 600 | 600 |

| 2.0 | |||||||

| 2.3 | |||||||

| 2.5 | |||||||

| 2.8 | |||||||

| 3.2 | |||||||

| 4.0 | 450 | 450 | 450 | 450 | |||

| 4.5 | 360 | 360 | 360 | 360 | 360 | 360 | |

| 5.0 | 290 | 290 | 290 | 290 | 290 | 290 | |

| 6.0 | 200 | 200 | 200 | 200 | 200 | 200 | |

※The above figures are for the material having yield strength of 245N/mm2 max.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us