LCC HF5 Series (w: 50 ~ 600 mm, t: 0.3 ~ 4.5 mm) ECO & SILENT Release

Equipped with the ECO & SILENT release mechanism for further improved productivity!

The latest ECO & SILENT release mechanism significantly reduces air consumption

Features

- 1. The latest ECO & SILENT release mechanism significantly reduces air consumption

-

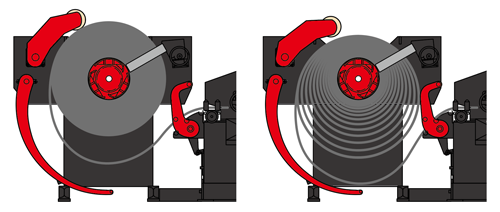

Along with automatic pressure adjustment to match leveling, optimum control of the release stroke has three effects:

1. Air consumption reduced by up to 75% compared to conventional models with air release

2. Release noise reduced by approximately 6.5 dB

3. Up to 20% improvement in release tracking performance (120 min-1)

- 2. Straightener Vertical Opening/Closing Mechanism for easy maintenance

-

Releasing the upper and lower covers has become much easier, making cleaning the rolls smoother. This contributes to stabilizing product processing and improving quality.

Upper part Lower part

- 3. Simplified Analog Loop Control improves quality and saves on labor

-

Analog loop cont rol , which was previously an option, is now standard equipment. This function ensures that the line and unwinding speed are at the same constant speed, preventing the uncoiler from stopping. This reduces the amount of coil material that is unwound, thereby reducing flaws in the material and improving product quality. In addition, it facilitates midway replacement of coiled material reducing the operator's workload.

With analog loop control Without analog loop control

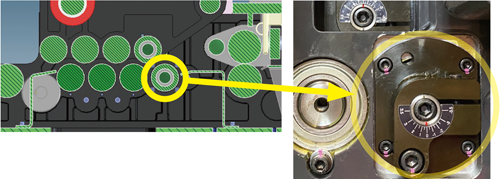

- 4. Increased number of work rolls improves flatness

-

The number of work rolls has been increased from seven to eight, resulting in an approximately 30% improvement in flatness after straightening. Two pilot rolls instead of one on the conventional machine facilitate fine adjustment of the material tip.

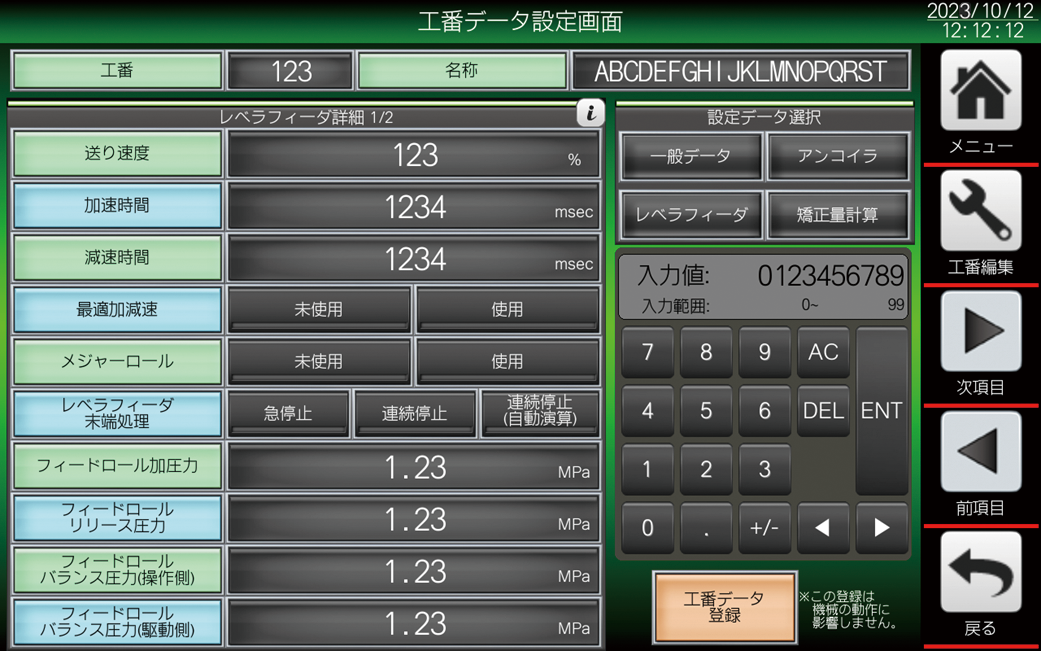

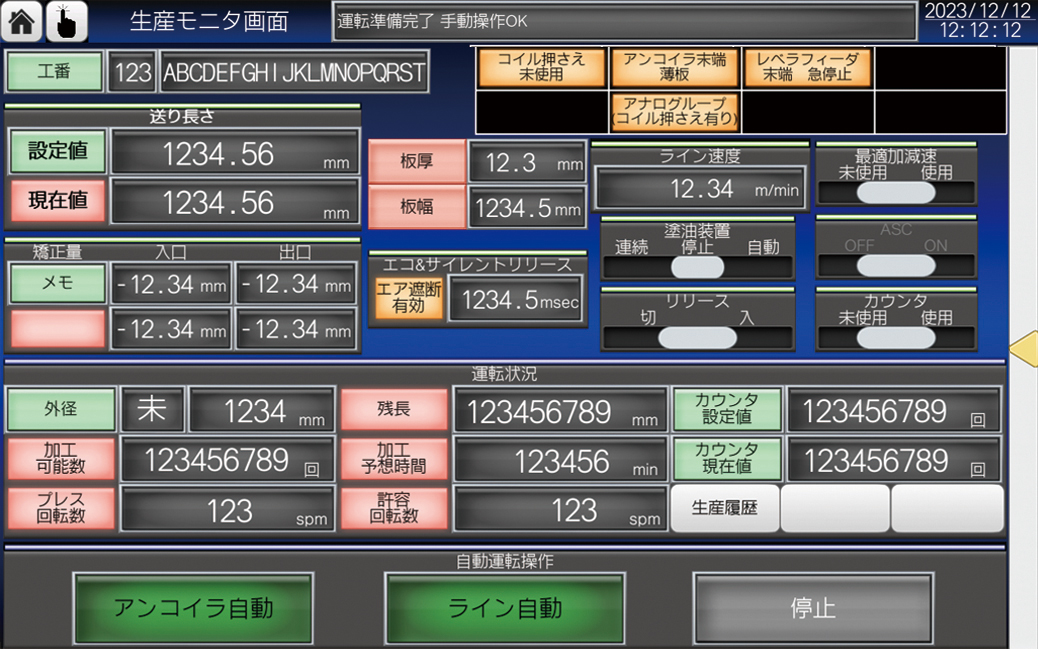

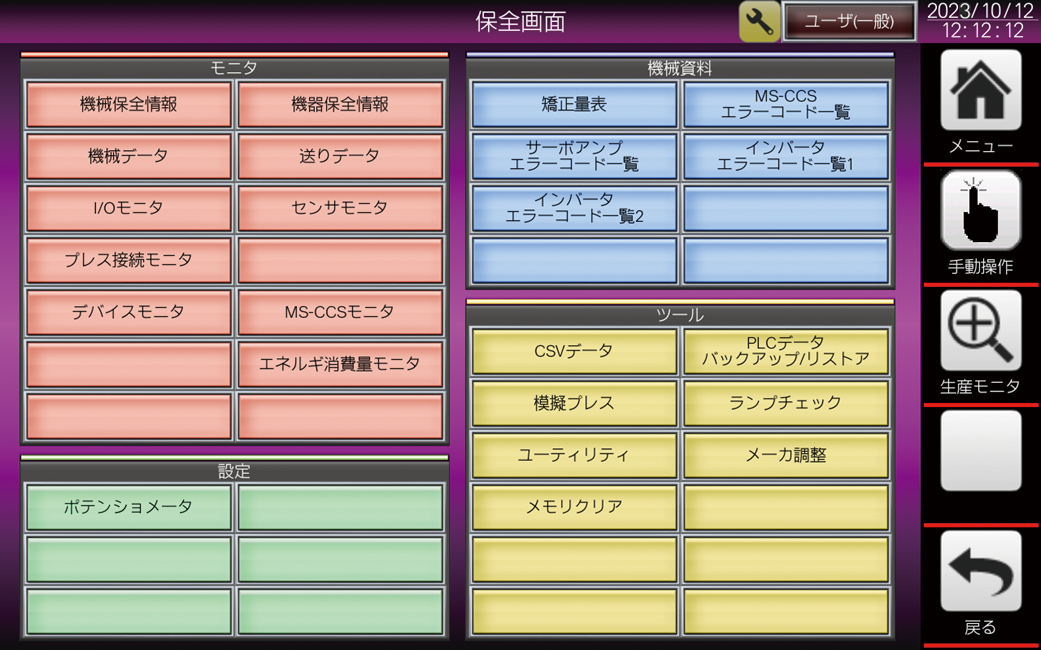

- 5. State-of-the-art CCS Control System with Touch Panel

-

All necessary information is centrally managed in eight basic modes, including manual operation, data setting, production monitoring, and maintenance. Equipped with various functions such as an energy-saving timer that can reduce power consumption, this total operation system responds to the diversification and sophistication of products and the reduction of work hours.

● Job Number Data Setting

● Manual Operation

● Production Monitor

● Maintenance

Specifications

| Model name | LCC04HF5 | LCC06HF5 | |

|---|---|---|---|

| Stock width | mm | 50 ~ 400 | 50 ~ 600 |

| Stock thickness | mm | 0.3 ~ 4.5 | 0.3 ~ 4.5 |

| Max. coil mass | kg | 3000 | 3000 |

| Max. coil outer diameter | mm | ø1400 | ø1400 |

| Coil inner diameter | mm | ø508 | ø508 |

| Feed length* | mm | ~ 500 | ~ 500 |

| Max. line speed | m/min | ~ 24 | ~ 24 |

| Work rolls (upper/lower) | Pieces | 4 / 4 | 4 / 4 |

| Mandrel expansion | Pneumatic | Pneumatic | |

| Power supply | V | 3-phase AC 200/220 | 3-phase AC 200/220 |

| Air pressure | MPa | 0.5 | 0.5 |

* If the feed length exceeds the standard specifications, Master Control (optional) must be provided.

Straightening performance

| Stock thickness mm |

Stock width mm |

|

|---|---|---|

| LCC04HF5 | LCC06HF5 | |

| 0.3 | 400* | 600* |

| 0.4 ~ 1.6 | 400 | 600 |

| 1.8 | 400 | 512 |

| 2.0 | 400 | 445 |

| 2.3 | 400 | 374 |

| 2.5 | 400 | 339 |

| 2.8 | 379 | 298 |

| 3.2 | 315 | 256 |

| 4.0 | 220 | 201 |

| 4.5 | 174 | 174 |

The table above shows the case where the yield point of the material is 245 MPa. The corrective ability values are the same for both standard and high speed.

* Only coil material threading

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for overseas specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us