LCC SA Series (w: 50 ~ 400 mm, t: 0.3 ~ 3.2 mm)

Forming the future for straightener/feeders

The straightening roll adjustment wheel has disappeared!

Fitted with all new technologies, including the first ever Active Straightening Correction(ASC) mechanism.

Presenting a revolution on the press processing floor.

Features

- ■ Features(1) : Active Straightening Correction (ASC)

-

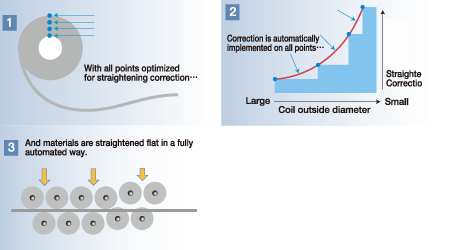

Given the difference in coil at the beginning of a roll and the end of a roll, it is usually necessary for an operator to always be monitoring straightening operations, and to manually carry out corrections to ensure a high degree of precision in straightening. With the unique ASC mechanism fitted on the LCC SA Series Straightener/feeder, changes in the coil outside diameter are detected during production. Straightening correction is performed continuously and automatically. Thanks to this innovation, the burden on line operators is reduced, meaning they do not have to be permanently by the machine, thus making a significant contribution to operational efficiency.

【Problem solutions】

・Operators can monitor other lines

・Operators can multi-task

・Cost reduction

- ■ Features(2) : Fitted with 11 rolls

-

The SA series ability to provide superior flatness comes from the 6 upper and 5 lower work rolls with a diameter of 48mm each. This construction, together with the ASC function, will further enhance the reliability of straightening.

- ■ Features(3) : Lift and Roll Easy Open Function

-

Work roll and feed roll are automatically fed into the port opening. In previous models only one side of the feeder opened, limiting the size of the port and making maintenance of the inner components difficult. With the new Lift and Easy Open Function of the SA Series, the port opening is a maximum 140mm, making cleaning of rolls even easier.

- ■ Features(4) : TP-CCS Controller Equipped with the newest touch-panel TP-CCS Control system

-

A wide variety of information needed for planning, operation, maintenance, etc, is uniformly controlled under the base mode of “Settings, Planning, Operaion, and Maintenance”. Equipped with various new operations, it is a complete operation system that responds to diversification and sophistication of merchandise and reduction of work time.

Specifications

| Model | LCC03SA | LCC04SA | |

|---|---|---|---|

| Stock Width | (mm) | 50~300 | 50~400 |

| Stock Thickness | (mm) | 0.3~3.2 | |

| MAX.Coil Mass | (kg) | *2 2,500/2,000 | |

| MAX.Coil O.D. | (mm) | 1,200 | |

| Coil I.D. | (mm) | 508 | |

| Feed Length | (mm) | *1~300 | |

| MAX.Line Speed | (m/min.) | ~16 | |

| Release-follow Speed MAX. | (spm) | 180 | |

| Work Roll Number | ― | upper6/lower5 | |

| Main Motor | (kW) | AC2.0 | |

| Mandrel Expansion | ― | *2 Manual/Pneumatic | |

| Reel Motor | (kW) | 0.75 | |

| Power | (V) | 200/220 | |

| Operating Air | (MPa) | 0.49 | |

*1:In case Feeding Length exceeding Specification, MASTER CONTROL Function (Option) must be provided.

*2:(Pneumatic):Option in case of Pneumatic mandrel expansion is provided, refer to coil weight in ( ).

Straightening Performance

| Stock Thickness | LCC03SA | LCC04SA |

|---|---|---|

| 0.3 | 300 | 400 |

| 0.4 | ||

| 0.6 | ||

| 0.8 | ||

| 1.0 | ||

| 1.2 | 330 | |

| 1.4 | 270 | |

| 1.6 | 270 | 230 |

| 1.8 | 230 | 200 |

| 2.0 | 210 | 185 |

| 2.3 | 170 | 150 |

| 2.5 | 160 | 140 |

| 2.8 | 130 | 120 |

| 3.2 | 100 | 100 |

※ The unit in the above table is represented in millimeters.

※The above figures are for the material having yield strength of 245N/mm2 max(tensile strength of 392N/mm2).

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us