LCC KR5 Series (w: 50 ~ 400 mm, t: 0.3 ~ 3.2 mm) ECO & SILENT Release

Productivity and Operability condensed into a Compact Straightener-Feeder!

The latest ECO & SILENT release mechanism significantly reduces air consumption

Features

- 1. The latest ECO & SILENT release mechanism significantly reduces air consumption

-

Along with automatic pressure adjustment to match leveling, optimum control of the release stroke has three effects:

1. Air consumption reduced by up to 50% compared to conventional models with air release

2. Release noise reduced by approximately 3.5 dB

3. Up to 17% improvement in release tracking performance (140 min-1)

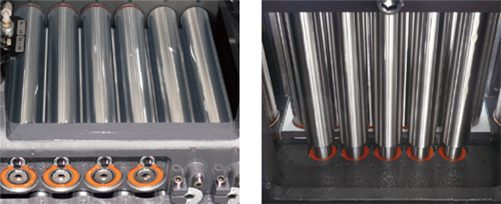

- 2. The Flattening ability of 11 work rolls contribute to high-precision processing

-

six upper and five lower rolls, are employed. This improves the flatness of coiled material and supports high-precision stamping.

Upper part Lower part

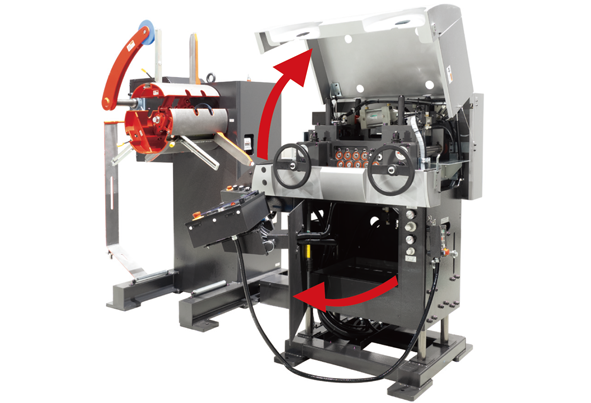

- 3. Roll cleaning mechanism for easy maintenance

-

The straightener is designed to be open on both upper and lower sides. Roll cleaning can be done easily, contributing to stabilization of product processing and quality improvement. In addition, maintenance time can be reduced.

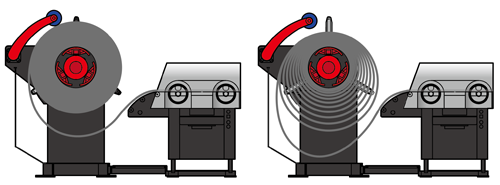

- 4. Simplified Analog Loop Control improves quality and saves on labor

-

Analog loop control ensures that the line speed and unwinding speed are at the same constant speed, preventing the uncoiler from stopping. This function reduces the amount of coil material that is unwound, thereby reducing flaws in the material and improving product quality. In addition, it facilitates midway replacement of coiled material, thereby reducing the operator's workload.

With Analog Loop Control Without Analog Loop Control

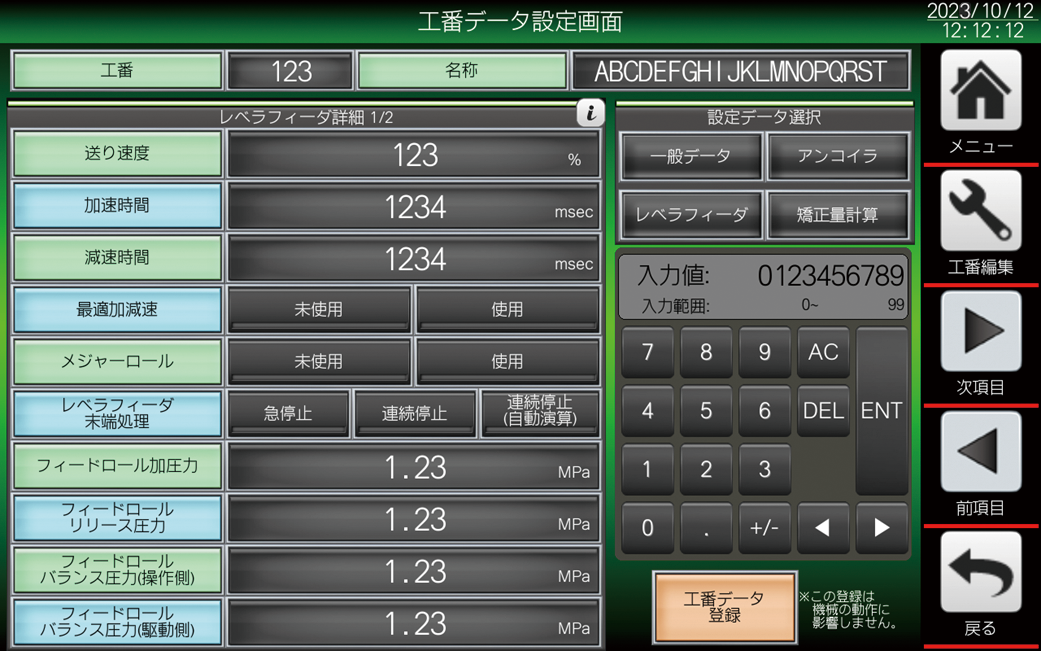

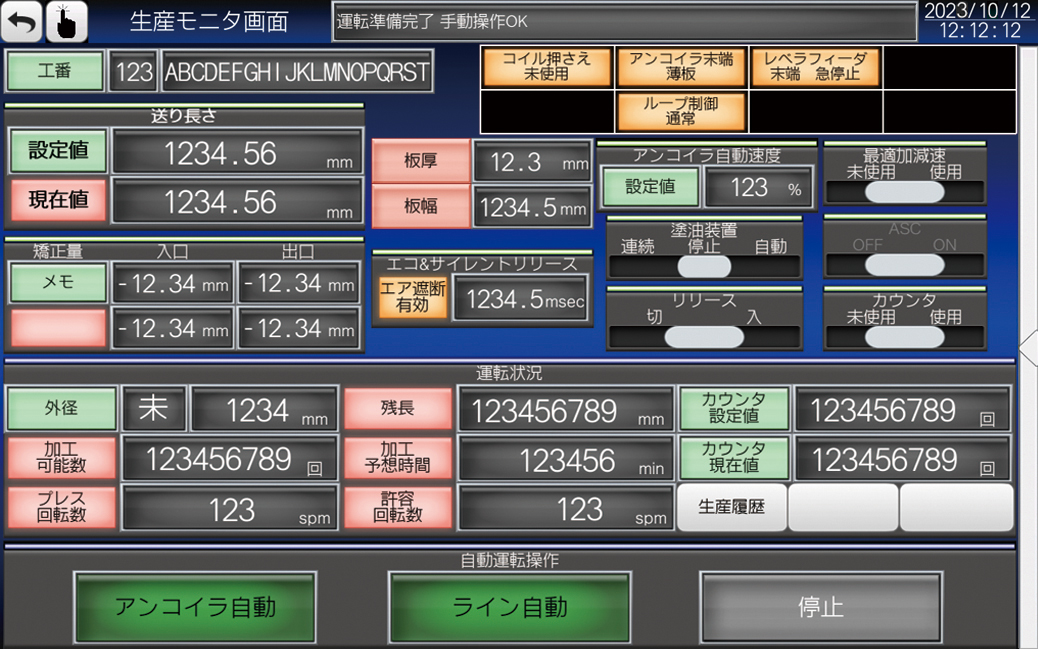

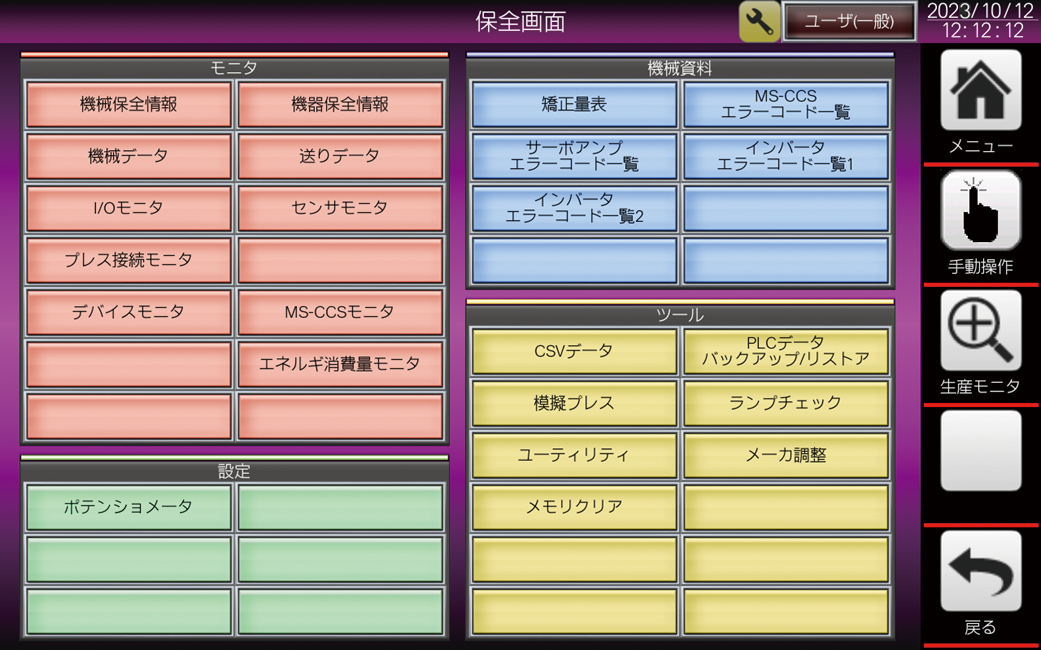

- 5. State-of-the-art CCS Control System with Touch Panel

-

All necessary information is centrally managed in eight basic modes, including manual operation, data setting, production monitoring, and maintenance. Equipped with various functions such as an energy-saving timer that can reduce power consumption, this total operation system responds to the diversification and sophistication of products and the reduction of work hours.

● Job Number Data Setting

● Manual Operation

● Production Monitor

● Maintenance

Specifications

| Model name | LCC03KR5 | LCC04KR5 | |

|---|---|---|---|

| Stock width | mm | 50 ~ 300 | 50 ~ 400 |

| Stock thickness | mm | 0.3 ~ 3.2 | 0.3 ~ 3.2 |

| Max. coil mass* | kg | 2000 (2000) | 2500 (2000) |

| Max. coil outer diameter | mm | ø1200 | ø1200 |

| Coil inner diameter | mm | ø508 | ø508 |

| Feed length** | mm | ~ 400 | ~ 400 |

| Max. line speed | m/min | ~ 16 | ~ 16 |

| Work rolls (upper/lower) | Pieces | 6 / 5 | 6 / 5 |

| Mandrel expansion* | Manual (Pneumatic) | Manual (Pneumatic) | |

| Power supply | V | 3-phase AC 200/220 | 3-phase AC 200/220 |

| Air pressure | MPa | 0.5 | 0.5 |

* Pneumatic Mandrel Expansion is optional. Refer to coil mass in ( ).

** If the feed length exceeds the standard specifications, Master Control (optional) must be provided.

Straightening performance

| Stock thickness mm |

Stock width mm |

|

|---|---|---|

| LCC03KR5 | LCC04KR5 | |

| 0.3 ~ 1.2 | 300 | 400 |

| 1.4 | 300 | 360 |

| 1.6 | 300 | 300 |

| 1.8 | 300 | 260 |

| 2.0 | 270 | 220 |

| 2.3 | 230 | 190 |

| 2.5 | 190 | 170 |

| 2.8 | 150 | 150 |

| 3.0 | 130 | 130 |

| 3.2 | 110 | 110 |

The table above shows the case where the yield point of the material is 245 MPa. The corrective ability values are the same for both standard and high speed.

These specifications, machinery, equipment, and appearance are subject to change without notice for reason of improvement.

Please contact us for overseas specifications.

Contact Us

Contact for repair/recovery of AMADA PRESS SYSTEM products and our corporate activities.

Contact Us