MM-140A

Checker for pulsed TIG welding is debut!

“Visible” welding quality management will be achieved!

Compact design and standing type.

Weld checker to measure current / voltage / time / gas flow rate in pulsed TIG welding.

Upper / Lower limit judgement is available.

Features

- ■ Measurement and judgement of necessarily monitoring factors for TIG welding are possible.

-

Upper / Lower limits of judgement and data management of factors are possible.

Welding quality is effected by below factors.- Current : the most important factor for welding.

- Voltage : It can be a factor that provides voltage-noise against welding point or peripheral devices.*1

- Time : important factor for welding as well as current.

- Shield-gas flow : it's necessary to discharge an arc stably.*2※2

We must measure and manage above factors.

*1: Available for touch-start welding.

*2: Our recommended flow rate sensor and input connector are connected.

welded sample

MAWA-050A/300B

Please ask for our pulsed TIG welders, too - ■ Measuring of long-time welding

- Maximum measurement time is 9999ms, thus, it’s available for long-time pulsed TIG welding.

- ■ Able to measure even while modulation function is operated.

- The modulation function is used to suppress welding faults such as blowholes.

In case of using complex waveforms control function, it enables to measure and judge each factors. - ■ Ethernet communication

- With connecting PC through LAN cable (Ethernet), uniform management is available.

The product offers one way and two way communications. In case of two way communication, reading/writing of measurement settings and data are possible. - ■ Accessaries (Options)

-

- Current sensor

Two types of sensors are on line-up. The one is used for detecting max. 50A and the other one is used for detecting max. 300A. Customers need to choose suitable sensor. - Torch voltage detecting cable (length 3m)

SK-1202980 - Relay cable (length 0.2m)

SK-1202967 - Flow rate sensor cable (length 3m)

SK-1202981 - Flow rate sensor

Please use our recommended product.

Calibration of the sensor is not done by our company, thus, customers should prepare the sensor by themselves.

RS-C300-3000/RS-C050-3000(Cable length 3m) - Current sensor

Specifications

| MODEL | MM-140A | ||||||

| Measurement Specification | Current | Range | 01.00 to 50.00A / 015.0 to 300.0A | ||||

| Items | Peak current within all welding time / RMS current from start signal input to end signal input | ||||||

| Voltage *1 | Range | 001.0 to 120.0V | |||||

| Items | Peak voltage within all welding time / RMS voltage from start signal input to end signal input | ||||||

| Measurement time | Range | 0000 to 9999ms | |||||

| Gas flow rate | Range | 00.0 to 10.0(4-20mA) *2 | |||||

| Items | Average value from start signal input to end signal input (from Pre-flow to After-flow) |

||||||

| Measurement time | 00000 to 50000ms(±3ms) | ||||||

| Modulation frequency | Range | 0~3000Hz(reference) | |||||

| Measurement accuracy | ±2% expect for an error of sensor | ||||||

| Judgement functions | Good-bad judgement based on upper/lower limits of current, voltage, time, gas flow rate and modulation frequency / no current judgement | ||||||

| No. of schedules | 31 schedules | ||||||

| Main body specification | Power supply | Single-phase 90 to 250 V AC(50/60Hz) / 24 V DC ±10% | |||||

| Power consumption | 17W | ||||||

| External data output | Ethernet(Protocol: TCP/IP) | ||||||

| Ambient temperature / humidity during operation | Temperature 0 to 45℃ / humidity less than 90%(non-condensation) | ||||||

| Temperature / humidity during transport | Temperature -10 to 55℃ / humidity less than 90%(non-condensation) | ||||||

| Outer dimensions・Mass | 70(W)×250(D)×187(H)mm (Not including projections) / Approx. 2.3kg | ||||||

*1 Measurement of voltage is available for only touch-start welding.

*2 It depends on specification of the gas flow rate sensor.

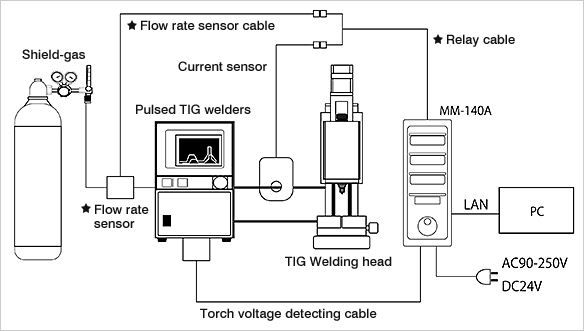

Configuration of connecting

If flow rate sensor is not used, please note that items with ★ icons are necessary.

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support