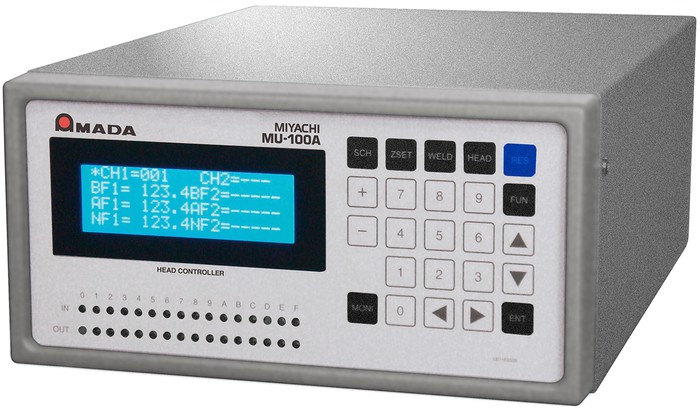

HEAD CONTROLLER MU-100A

Weld head controller with monitoring weld force and displacement!

Plaese click here to get the manual

Quality control of fine spot welding

It is important to control the weld current, voltage, welding time, applied force and displacement for improvement of fine spot welding quality.

AMADA WELD TECH offers MU-100A Head contoller for measuring applied force and displacement and MM-Series Weld checker for measuring weld current, voltage, and welding time to sustain weld quality.

Features

- ■ Weld head control and force and displacement measument.

-

Head Control and sequence function not provided by MM-Series weld checker are available.

Nine types of measurement modes with a variety of functions including monitoring displacement before welding and setting internal zero reset. - ■ Corresponding displacement sensors and load cells are newly added.

-

The displacement sensor is available from 0 to 25mm, and the load cell is from 0 to 10kN.

Contact AMADA WELD TECH for more information. - ■ Up to four channels to monitor simultaneously: Two force sensors and two displacement sensors.

-

Available even when series welding, parallel gap welding, and indirect welding.

- ■ Up to 127 schedules can be saved.

- ■ Offset adjustment of controller for each sensor

-

* For calibration, please send us your displacement sensor and force sensor together with the MU-100A. We conduct calibration at our site and issue calibration certificate with charge.

* The calibration is conducted for only the sensor purchased from AMADA WELD TECH.

* For the load cell with 10kN or over, contact AMADA WELD TECH.

Specifications

| Model | MU-100A-00-00 (1-axis type: Force 1 and Displacement 1) |

|

| MU-100A-00-01 (2-axis type: Force 2 and Displacement 2) |

||

| Power supply | Single-phase, 100 to 240 VAC±10% (50/60Hz), 0.5 A | |

| Operating environment | Temperature 5 to 40℃, Humidity 90% or less | |

| Storage environment | 0 to 55℃ | |

| Number of schedules | 127 | |

| Communication | Ethernet, RS-232C, RS-485 | |

| Displacement sensor (Options) |

Measurement range | 0 to ±50.000 mm *1 30-mm displacement sensor or shorter:±0.015 mm *1 50-mm displacement sensor: ±0.025 mm *1 |

| Load cell (Options) |

Measurement range | 0 to 10kN *2 (Accuracy: ±3% of full scale) |

| Mass | 3.3kg | |

*1*2 In case of using the sensor purchased from AMADA WELD TECH.

*2 For the load cell with 10kN or over, contact AMADA WELD TECH.

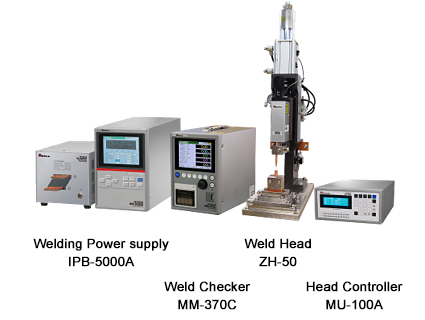

Connection with peripheral devices

- Futher welding quality control can be realized using with our weld checkers.

-

Measurement Mode

| Sequence Mode |

|---|

| Measures the thickness of a workpiece before welding and measures its displacement value after welding. |

|

| Sample Hold 1 Mode |

|---|

| Measures the thickness of a workpiece at your designated point. |

|

| Sample Hold 2 Mode |

|---|

| Measures displacement after zero-resetting prior to welding. It stops welding when the displacement value reaches the set value. |

|

|

| Sample Hold 3 Mode |

|---|

| Measures the thickness of a workpiece and its displacement at a given point in time. When to start and end measuring can be set. |

|

| Synchro Mode |

|---|

| Measures force, the thickness of a workpiece, and displacement both before and after weling. |

|

| (Force) Sequence Mode |

|---|

| Measures force prior to welding and starts welding when the force is judged to be appropriate. |

|

| (Force) Sample Hold 1 Mode |

|---|

| Measures force at a given point in time. |

|

| (Force) Sample Hold 2 Mode |

|---|

| Starts welding when the force reaches the set value and measures the maximum force during welding. |

|

| Tangential Mode |

|---|

| Starts welding when the force reaches the set value and measures force after welding. |

|

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support