Servo Motor Driven Weld Head MH-108B/MH-109B

Features

- ■ Detachable force follow-up mechanism.

-

Optimum force follow-up mechanism can be attached depends on an application.

- ■ Custom-made.

-

Force follow-up mechanism has a variety of electrode holders. Diameter of electrodes and set direction of electrodes; straight or eccentric, can be selected for a wide range of applications.

- ■ Easy programming.

-

It needs only turning and pressing a dial of attached controller.

- ■ Equal weld quality can be obtained even by beginners.

-

Servo motor driven type does not need any special skill to get great weld quality.

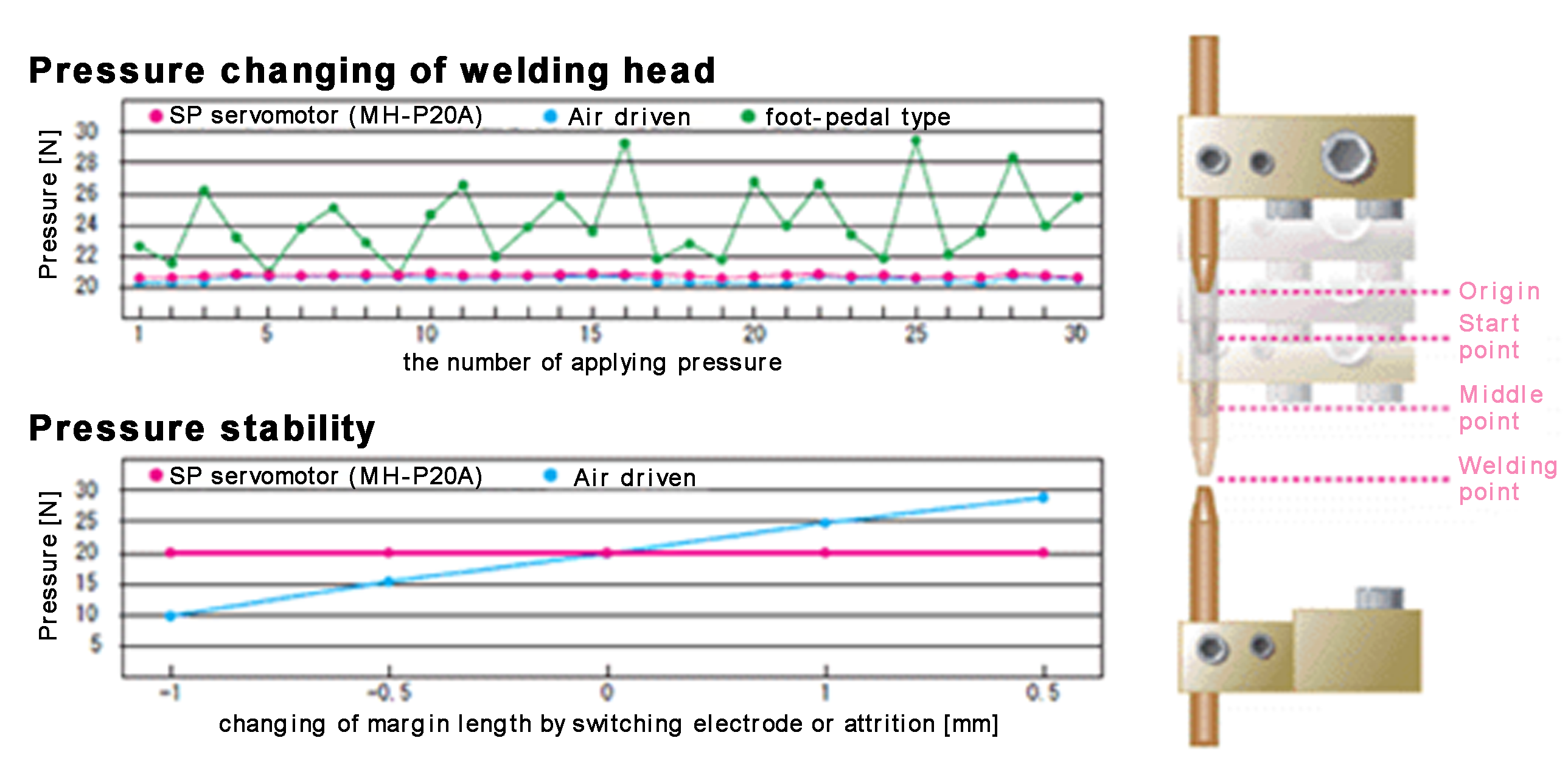

- ■ Stable force can be applied.

-

Spring pressurization and servo motor ensure weld repeatability. Applied force is kept stable regardless of electrode's length.

- ■ "Soft-touch" part clamping.

-

It minimizes impact force and allows verification of part alignment prior to welding.

- ■ Easy installation.

-

Due to a motor driven, no piping is necessary.

- ■ Overforce protection.

-

It ensures concise, repeatable force, less weld splash, reduced part deformation.

-

Specifications

| Model | MH-108B | MH-109B |

| Head type | For direct welding | For direct welding / series welding |

| Drive method | Servomotor | |

| Corresponding force follow-up mechanism | VPW-S | VPW-S/VBW-S/VTW-S |

| Maximum weld force | VPW: 7kgf (70N) | VPW: 7kgf (70N) VBW,VTW: 3.5kgf (35N) each |

| Top electrode holder | Water-cooling pre-set | Pararell moving |

| Bottom electrode holder | Model dedicated to MH-108A | XY-30 (Φ3, 5, 8) |

| Diameter of electrode | Φ3 | Φ3 |

| Stroke | 50mm (Minimum solution: 0.1mm) | |

| Number of schedule | 31 (Switchable from external device) | |

| Datacom | RS-232C/RS-485, 9600bps | |

| Power requirements | 100 to 240VAC +/-10%, 50/60Hz | |

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support