For DC spot welding / fusing: IS-800A/1400A

Features

- ■ Primary current PEAK control enables detailed parameter settings.

- The control features below are only available when Primary current PEAK is selected.

- Voltage compensation

It is to adjust set values for Pulse limit depending on primary voltage fluctuation before welding.- When 190VAC (-5%), pulse width set for Pulse limit is adjusted to increase 5%.

- When 210VAC (+5%), pulse width set for Pulse limit is adjusted to decrease 5%.

- Pulse limit

This is to limit pulse width when current is up-sloping.

- Voltage compensation

- ■ Ground fault and short-circuit protections ensure the safety better.

- ■ Adjustable welding frequency from 600 to 3000kHz with 100Hz increment.

- ■ Program protect feature prevents false operation due to unintended touches to the screen.

- ■ Up to the third welding is controllable. Pulsation and other control modes can be set for each welding.

- ■ Interrupt feature

-

Interrupt feature functions when a displacement amount reaches up to set level and stops current to obtain stable fusing. For this feature, it needs to be connected with a weld checker with a built-in displacement monitor and set a displacement amount of electrodes beforehand.

-

- ■ Six kinds of control methods

-

Select an optimal control method for an application: Primary current effective value control, secondary current effective value control, secondary power effective value control, Primary current peak value control, secondary voltage effective value control, and constant phase control.

- ■ Three kinds of monitoring

-

Current, voltage, or power can be monitored.

- ■ Safety features

-

Overcurrent detector, no-current/no-voltage detector, heat abnormality detector, and self-check feature protect your safety.

- ■ Two kinds of welding time unit

-

ms or cycle can be selected.

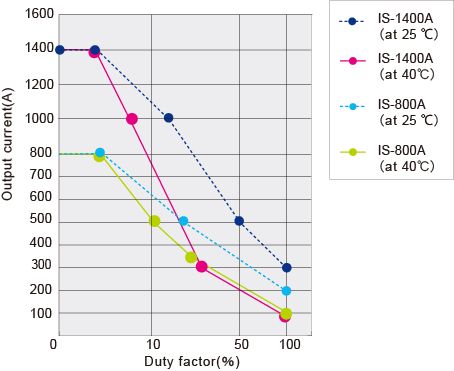

- ■ Duty factor and Output current

-

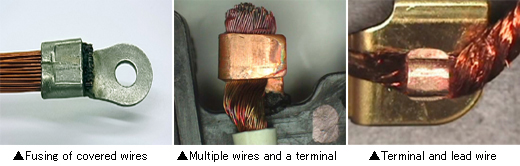

- ■ Samples

-

Specifications

| Model | IS-800A | IS-1400A | |

| Power requirements | ・Three phase, 380-480VAC (50/60Hz)10% ・Three phase, 200-240VAC (50/60Hz)10% |

・Three phase, 380-480VAC (50/60Hz)10% ・Three phase, 200-240VAC (50/60Hz)10% |

|

| Maximum output current | 800A (3%) | 1400A (3%) | |

| Number of schedules | 255 | ||

| Output frequency | 600Hz to 3kHz | ||

| Control method | Primary current RMS/ Secondary current RMS/ Secondary power RMS/ Primary current PEAK/ Secondary voltage RMS/ Constant phase | ||

| Timer setting | msec mode cyc mode | ||

| SQUEEZE DELAY | 0000 to 9999ms 000 to 999cyc | ||

| SQUEEZE | 0000 to 9999ms 000 to 999cyc | ||

| UP SLOPE 1,2,3 | 000 to 999ms 00 to 50cyc | ||

| WELD 1,2,3 | 000 to 999ms 00 to 50cyc | ||

| DOWN SLOPE 1,2,3 | 000 to 999ms 00 to 50cyc | ||

| COOL 1,2 | 000 to 999ms 00 to 99cyc | ||

| HOLD | 00000 to 20000ms 000 to 999cyc | ||

| OFF | 0 or 0010 to 9990ms 00 to 99cyc | ||

| Transformer turn ratio | 1.0 to 199.9 | ||

| Pulsation setting | 01 to 19 | ||

| Valve setting | 2 | ||

| Setting range (1)Constant current (2)Constant power (3)Constant voltage (4)Constant phase |

(1)0.05 to 40.0kA (2)0.05 to 60.0kW | (1)0.05 to 80.0kA (2)0.05 to 120.0kW | |

| (3)0.20 to 9.99V (4)10.0 to 99.9% | (3)0.20 to 9.99V (4)10.0 to 99.9% | ||

| Current monitor | HIGH 0.00 to 9.99kA / LOW 0.00 to 9.99kA | HIGH 00.0 to 99.9kA / LOW 00.0 to 99.9kA | |

| Power monitor | HIGH 0.00 to 9.99kW / LOW 0.00 to 9.99kW | HIGH 00.0 to 99.9kW / LOW 00.0 to 99.9kW | |

| Voltage monitor | HIGH 0.00 to 9.99V / LOW 0.00 to 9.99V | ||

| Pulse width monitor | 10 to 100% | ||

| Installation environment |

Ambient temp. | +5 to +40℃ | |

| Max. humidity | 90% (No condensation) | ||

| Max. altitude | 1000m or below | ||

| Mass | 38kg | 60kg | |

Transformers that are selectable

| For IS-800A/1400A | ||||

| Model | SIT-F241-HC | MIR109-69060 | MIR115-39060 | |

| Rated capacity | 75kVA (50%) | 90kVA | ||

| Rated primary voltage | 300V | 600V/650V | 300V/325V | |

| No-load secondary voltage | 12.5V | 10.9V/11.8V | 11.5V/12.5V | |

| Transformer turns ratio | 24:1 | 55:1 | 26:1 | |

| Input frequency | 1kHz | 600Hz/1kHz | ||

| Maximum welding current | 14400A | 18000A | ||

| Duty cycle | 10% | |||

| Cooling method | Water - coded | |||

| Mass | 35kg | 21kg | 23kg | |

| Dimensions (mm) * | 240 (W) × 481 (D) × 180 (H) | 167 (W) × 365 (D) × 155 (H) | 167 (W) × 435 (D) × 155 (H) | |

* Include projections

It's one of examples. Thare are some transfomers that are able to use with the power supply.

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support