Laser Weld Monitor MM-L300A

New suggestion of quality monitoring in laser welding!

Available for in-process monitoring!

Plaese click here to get the manual

A machine available for in-process monitoring in all welding.

Available for pulsed and CW laser by high speed resolution.

Light weight and compact design.

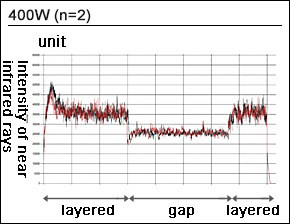

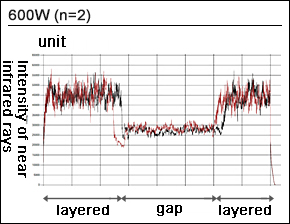

The welding monior detects near infrared rays generated in the welding and shows the intensity as waveform. We can compare the waveform of good welding that is monitored in advande and the other one that is detected just now.

The monitor is suitalble for welding quality management as detecting gap, depth of welding, and so on.

It's recommended for the customers who will use laser welder at first time or who are in trouble of welding quality management.

* It means the wavefrom that is monitored in sample test in advance.

Features

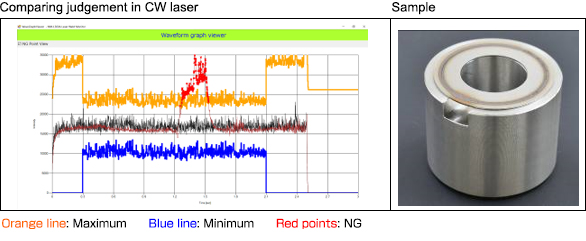

- ■ Comparison judgement

- Available for comparing good-data with bad-data. It's effective-use to judge in processing line. *Verifying in advance is needed.

-

- ■ High speed resolution

- Enable for high speed resolution with dedicated sensor. Monitoring not only CW laser but also pulsede laer.

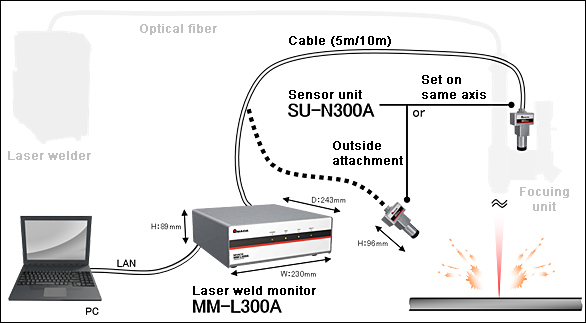

- ■ Configuration

- This is a configuration to use MM-L300A.

The product seems to be used in production lines. -

- ■ Light weight and Compact design

- Light weight and compact in this market. Reducing set-up space when you construct processing lines.

- ■ Sensor on axis and outside attachment

- The dedicated sensor can be equipped our focusing unit with CCD on axis and also can be set outside.

- ■ Easy to operate

- Controlling and preserving data in lap-top installed dedicated software.

- ■ Available for Ethernet (EtherNet/IP).

- It enables to monitor remotely or to manage all of data coming from each procution lines.

- ■ Compliance with CE marking

- * some options are not available. please ask us the details.

Specifications

Introduing of specifications.

| Model | MM-L300A | |||

| MM-L300A | Dimensions (mm) | 230(W)×243(D)×89(H) *Without connector | ||

| Power supply | Single phase AC90~250V 50/60Hz | |||

| Power consumption | Less than 18W | |||

| Interface | D-sub15 pin | |||

| Channel | 1 | |||

| Minimum resolution | 1μs | |||

| Monitoring time | 1μs~999sec | |||

| Comparison function | Analysis | Waveform | ||

| Judgement | Envelope (upper/lower limit setting) | |||

| Temperature in operation | 0~40℃ (No-condensation) | |||

| Humidity in operation | 85%RH or under (No-condensation) | |||

| Sensor | Dimensions (mm) | 50(W)×35(D)×96(H) *Without connector 50(W)×35(D)×106(H) *Equipping filter, without connector |

||

| Guide light | Green LED | |||

| Temperature in operation | 5~50℃ (No-condensation) | |||

| Humidity in operation | 85%RH or under (No-condensation) | |||

*Specifications subject to change without notice.

- ■ Waveform

| Schedule | layered seam welding / material:stainless steel 304 / power:check below / thickness:t0.3mm gap:3.0mm / time:0.8s / speed:80mm/s / sensor on axis |

- ■ Video

-

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support