400W ML-2550AM

These handheld welders are easy to use and allow high-quality laser welding to be performed with less burn and distortion.

Easy-to-handle "L-type" handy torch Anyone can easily perform YAG laser welding

- YAG laser welding can be manually performed by using the "L-type" handy torch.

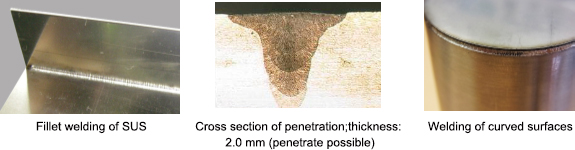

- Various metals (including stainless steel, mild steel, titanium, and some aluminum alloys) can be welded.

- The fast, repeated emission of the laser beam creates beautiful weld beads and eliminates clean-up.

- Up to 2.0 mm thick stainless steel sheets can be welded. *For welding thicker stainless steel sheets, contact AMADA MIYACHI.

- The handy torch is fitted with the safety function of automatically turning off the laser when it is moved off the workpiece.

- The torch is fully air cooled and constructed for high-efficiency discharge of the shielding gas from the tip.

- Various applications, including tack welding, correction, low-volume high-mix products, prototypes, and welding of thin sheets with less burn-through distortion.

Standard Features

Features

- ■ Handy torch

-

L-type and lightweight handy torch

High workability thanks to the lightweight, compact design with a “L-type” torch and a weight of 400g.

-

- ■ Example usage

-

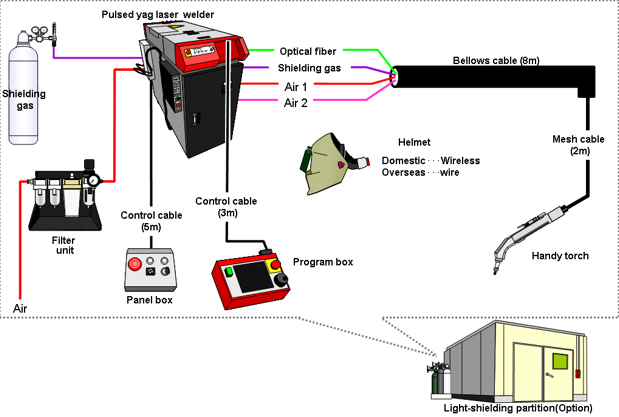

- ■ Equipment layout block diagram

-

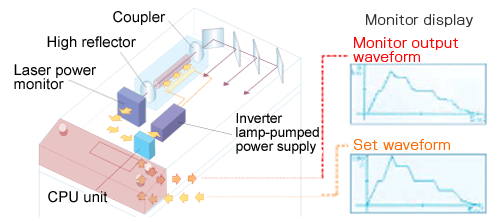

Real-time Power Feedback Control

The laser output in the lamp-pumped module is monitored in real time. The monitored laser output is compared with the set waveform and power is fed back in real time, varying the energy input to the lamp to reproduce the set waveform and obtain the ideal laser output waveform.

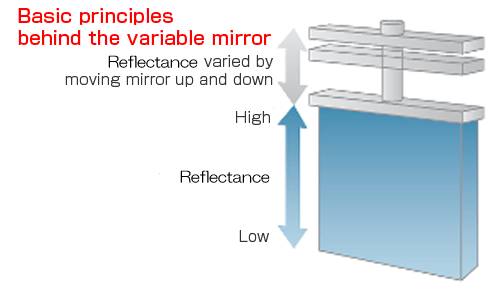

Variable mirrors

These mirrors eliminate laser power loss and improve branch balance.

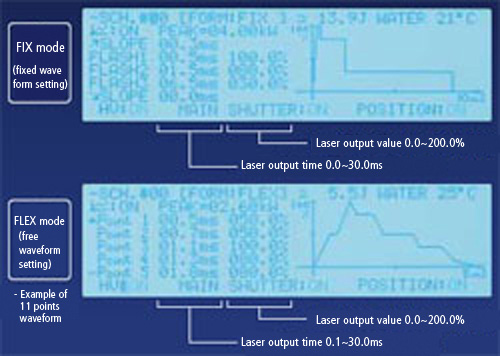

Waveform control

Equipped with a "fixed mode" that features three-level waveforms, and a "flex mode" to provide more complex waveforms.

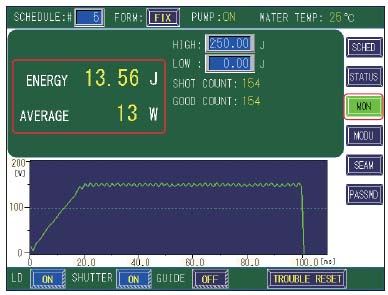

Power monitor

Laser energy (J) and average power (W) are monitored to detect abnormalities.

Controller

The controller can be detached from the main unit to operate at your hand.

External communications

Configuration of parameters and monitoring of performance can be carried out from a separate location.

- Type: RS-485 compliant, asynchronous, full duplex

- Data speed: 9600, 19200, 38400 bps

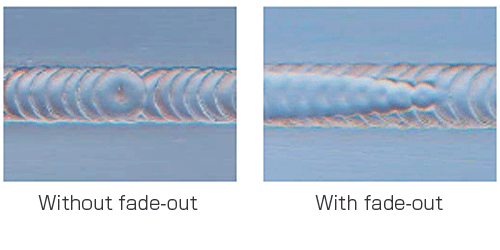

Fade-in/Fade-out

This feature avoids marks at the end of seam welding and provides a beautiful finish even for overlapping circumference seam welding sections.

Production Samples

Specifications

| Model | ML-2550AM | |

| Oscillation wavelength | 1064nm | |

| Laser output | Maximum rated output | 400W |

| Maximum energy | 80J/P | |

| Peak power | 8kW | |

| Pulse repetition rate | 1 to 500pps | |

| Fiber type | SI type Φ0.6mm | |

| Fiber optic delivery | 4-power sharing / 4-time sharing * | |

| Torch | Shape | L-type |

| Cooling method | Air cooled | |

| Spot diameter | ①:Φ0.9mm, ②:Φ0.8mm, ③:Φ0.7mm | |

| Dimensions | Laser oscillator | 530(W)×1347(D)×1170(H)mm |

| L-type handy torch | ①:309mm、②:300mm、③:296mm | |

| Controller | 63(W)× 320(D)× 330(H)mm | |

| Relay box | 80(W)× 270(D)× 450(H)mm | |

| Panel box | 150(W)× 120(D)× 80(H)mm | |

| Weight | Laser oscillator | Approx. 400㎏ (AC200V,220V,240V) Approx. 450kg (AC380V,400V) |

| L-type handy torch | 400g | |

| Safety device | Helmet, Light-shielding partition (Option) | |

* Each oscillator is equipped with one hand unit (additional output units can be used to share deliveries other than those that use the hand unit).

Applications

These welders can be used in various applications, such as temporary welding and modification during prototyping, high-mix low-volume production, mold repair, and cutting (optional nozzle required).

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support