600W FLW-600MT

With 600W oscillator

Space-saving, energy-saving fiber laser handy welder equipped

Forms continuous, smooth beads by continuous CW output.Its waveform controls widens pulses width which enables to weld various materials.

Its real-time power feedback improves the reproducibility of welding schedules, stabilizes welding performance and increases oscillation efficiency.

In addition, it requires no chiller, reducing power consumption.

Because Oscillator mirror and Flash lamp unnecessary,Running cost has been significantly reduced.

- 90% reduced of power consumption compare with "conventional 600W model "

- Fully air-cooling reduces consumable parts

- Real time power feedback feature enables stable processing

- Controllable waveform function enlarges adaptability for high reflectance materials

- Equipped the optical isolator as standard to prevent from optical damage to oscillator *1

- User friendly light weighted handy torch

- User friendly wireless helmet *2

*1: Not protection for optical damage on the fiber

*2: Wired helmet for CE complied model

Standard Features

Features

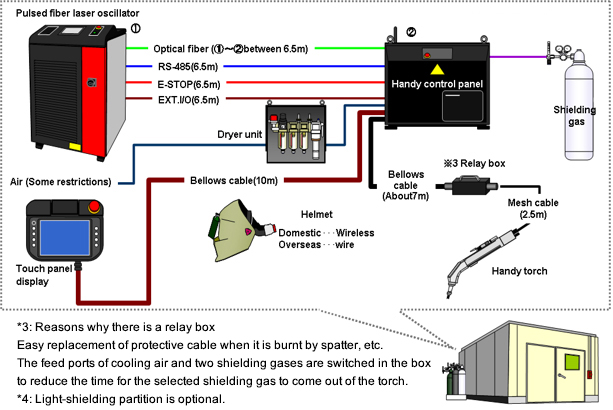

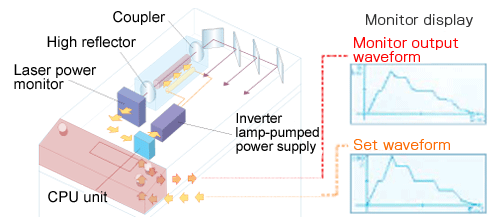

- ■ Equipment layout block diagram

-

Real-time Power Feedback Control

The laser output in the lamp-pumped module is monitored in real time. The monitored laser output is compared with the set waveform and power is fed back in real time, varying the energy input to the lamp to reproduce the set waveform and obtain the ideal laser output waveform.

Color LCD touch panel

The touch panel can be detached from the main unit and operated by hand.

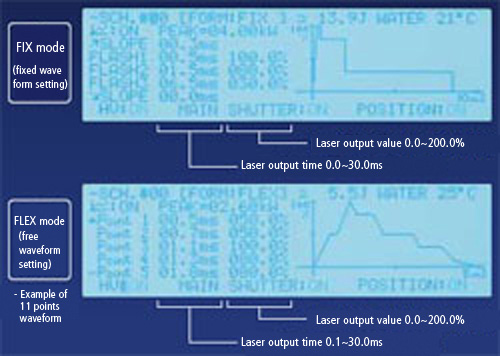

Waveform control

Equipped with a "fixed mode" that features three-level waveforms, and a "flex mode" to provide more complex waveforms.

External communications

Configuration of parameters and monitoring of performance can be carried out from a separate location.

- Type: RS-485 compliant, asynchronous, full duplex

- Data speed: 9600, 19200, 38400 bps

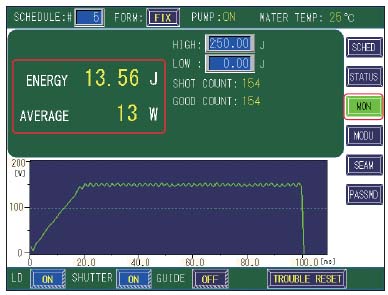

Power monitor

Laser energy (J) and average power (W) are monitored to detect abnormalities.

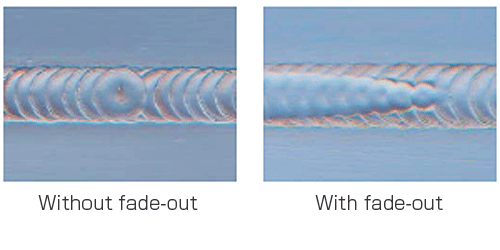

Fade-in/Fade-out

This feature avoids marks at the end of seam welding and provides a beautiful finish even for overlapping circumference seam welding sections.

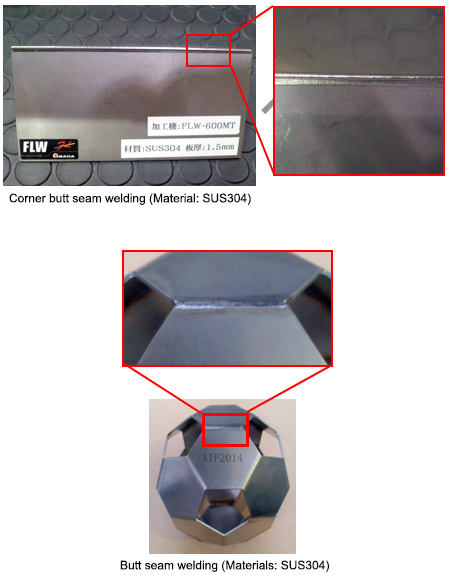

Production Samples

Specifications

【Handy torch】

| Type | Types of tip (L-type, straight-type) Built-in protective glass (Straight type is optional) |

| Weight | 460 g (L-type mounted) 395 g (Straight-type mounted) |

| Shield gas | Argon, nitrogen |

| Welding conditions | Manually select among 90 types (waveform No. 0 to 120)(waveform No. 0 to 74: standard conditions configured) |

| Accessories | ① Stand for hand-held torch: x 1 ② Protective gloves (leather): 1 set ③Protective gloves (conductive fiber): 5 sets ④ Protective glass (Φ12 mm, 2 mm thick): x 10 ⑤ Nozzle (Carbon, outer Φ7 mm, inner Φ5 mm, 20 mm long): x 50 ⑥ Nozzle (Carbon, outer Φ7 mm, inner Φ5 mm, 12 mm long): x 10 ⑦ Dust mask: 20 ⑧ Simple clean booth: 1 set |

【Oscillator: ML-3060AS】

| Oscillator | Maximum rated output (from oscillator) |

REPEAT mode | 600W |

| CW mode | 550W | ||

| Maximum peak power (from oscillator) |

REPEATmode | Maximum: 5.500kW Minimum (power feedback ON): 1.000kW Minimum (power feedback OFF): 600W |

|

| CW mode | Maximum: 550W Minimum (power feedback ON): 100W Minimum (power feedback OFF): 60W |

||

| Pulse width | REPEAT mode | Standard: 0.2 to 50.00 ms (0.1ms steps) [Energy (J)] x [Repetition (pps)] = 600 W or less However, the pulse energy is 60 J or less and the DUTY is 50% or less. Note: When using the output waveform of 1.200 kW, the pps value is limited to keep the average power below 600 W. As a result, the duty ratio becomes 50% or less. Also, when outputting a waveform with a shot (SHOT = 1), the READY signal is automatically turned off for certain time after laser output to keep the average power below 600 W, and the next laser start is not accepted. |

|

| CW mode | Standard: 0.1–1000.0 s (0.1s steps) | ||

| Repeated number of pulse/modulation | 1 to 1000 pps (REPEAT mode) | ||

| Modulation function | 1 to 5000 Hz (rectangular wave, triangular wave, sinusoidal wave) (CW mode) | ||

| Oscillation wavelength | Fundamental wavelength | ||

| Safety shutter | With open/close sensor | ||

| Positioning guide beam | Built-in visible laser (Red) | ||

| Prevention of reflected beam | Built-in reflected beam sensor | ||

| Output stability | ±2% or less@600 W per 4 hours (constant temperature) | ||

| Power Supply | Power Supply | Input power supply | Single-phase, 200 V to 240 V AC (+10%/-15%) |

| Frequency | 50/60Hz | ||

| Max. input current | 23A(200V)、21A(220V)、19A(240V) | ||

| Max. apparent power | 3.8kVA | ||

| Power consumption | Maximum | 3.5kW | |

| Standby | 0.2kW | ||

| Breaker rated curren | 30A | ||

| Dimensions | 750(W)×750(D)×1250(H)mm | ||

| Weight | 250kg or less | ||

Applications

- Food processing machine component

- Railroad-related products

- Sheet metal for various housing

- Precision sheet metal parts

- TIG welding, tack weld before brazing etc.

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support