120W ML-5120A

Direct Diode Laser Welder with "Active heat control™" function!

It's suitable for soldering and plastic welding applications.

Localized heating - Ideal for small parts and small spacing.

Plaese click here to get the manual

ML-5120A is a Direct Diode Laser Welder with maximum output of 120W and designed for high energy efficiency. The laser light is created directly from the diodes and does not need amplification in crystals such as Nd:YAG or Nd:YVO4. The output is directly used for thermal processing such as plastic welding and soldering applications. The Active heat control is a unique function that controls laser outputs to keep the heat input to the processing area constant according to the heat generated at the processing area detected by a coaxially-arranged heat detector.

Standard Features

Features

- ■ Features

-

- Dedicated ouput unit (FOCH-30B series) is necessary for function of Active heat control. *1

Soldering with Active heat control

- Energy saving

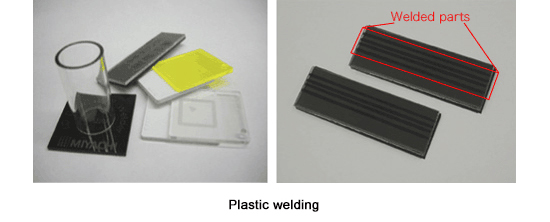

Direct Diode Laser Welder uses a light from the highly efficient diode directly to weld parts; its power consumption can be reduced. - Optimal for plastic welding

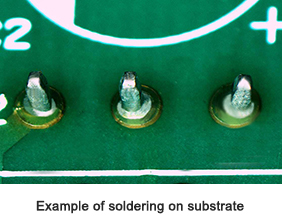

Because base materials themselves are bonded together, they can easily be recycled, thereby facilitating environmentally friendly plastic bonding. This eliminates the need to wait until the adhesive hardens, significantly reducing bonding time. - Suitable for laser soldering

The small spot diameter of 0.2 mm allows for fine soldering in high-density, small-pitch areas and small areas. In addition, Direct Diode Laser Welder can perform environmentally friendly lead-free soldering. - Optical fiber delivery system

Optical fiber delivery systems with Two energy-sharing deliveries are available. *2

Energy outputs improve productivity. - Power monitor as a standard equipment

- Dedicated ouput unit (FOCH-30B series) is necessary for function of Active heat control. *1

*1. No guarantee for the result.

This enables to maintain adequete heat input by controling laser power.

*2. Active heat control is available for either output when using energy share outputs.

*3. This product is subject to Japanese Export Control Law. Depending on its destination, prior assessment and authorization may be required. When exporting from country of initial purchase destination, please be sure to follow that country's export regulations as it may require an export permit beforehand.Details would like to ask you to inquire to business about it.

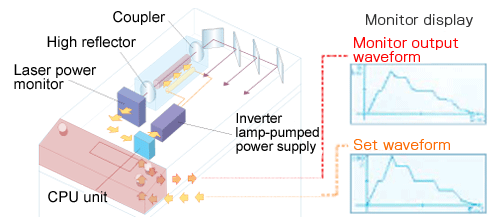

Real-time Power Feedback Control

The laser output in the lamp-pumped module is monitored in real time. The monitored laser output is compared with the set waveform and power is fed back in real time, varying the energy input to the lamp to reproduce the set waveform and obtain the ideal laser output waveform.

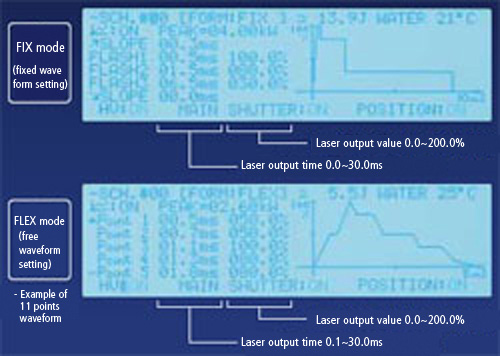

Waveform control

Equipped with a "fixed mode" that features three-level waveforms, and a "flex mode" to provide more complex waveforms.

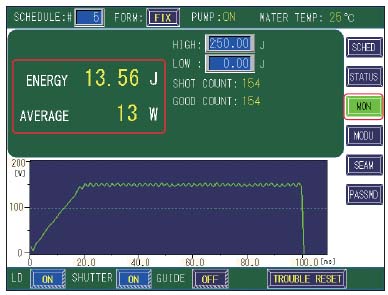

Power monitor

Laser energy (J) and average power (W) are monitored to detect abnormalities.

Color LCD touch panel

The touch panel can be detached from the main unit and operated by hand.

External communications

Configuration of parameters and monitoring of performance can be carried out from a separate location.

- Type: RS-485 compliant, asynchronous, full duplex

- Data speed: 9600, 19200, 38400 bps

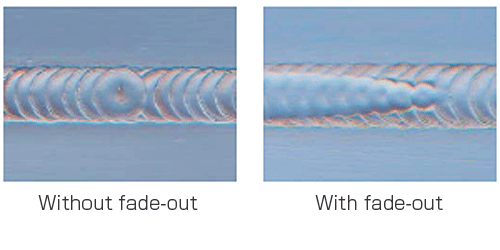

Fade-in/Fade-out

This feature avoids marks at the end of seam welding and provides a beautiful finish even for overlapping circumference seam welding sections.

Forced Air Cooling System

The air cooling system is available. No water and piping are necessary.

Production Samples

- Soldering Sample

-

- Plastic welding Sample

-

Specifications

| Model | ML-5120A | |

| Maximum rated output (from oscillator) | 120W | |

| Output control (Pulse/CW switching allowed) |

Pulse width | 0.1 to 500ms |

| Pulse repetition rate | 1 to 5000pps | |

| CW output | 1 to 10000sec | |

| Modulation function | 1 to 5000 Hz (rectangular wave, triangular wave, sinusoidal wave) (CW mode) |

|

| Wavelength | 915±15nm | |

| Safety shutter | With open/close sensor | |

| Positioning guide beam | Built-in visible laser (red) | |

| Output stability | ± 3% less @10W or more (Ambient temperature± 5℃within) | |

| Active heat control | Controls laser outputs detecting the heat at the processing area. * This function is available only with the FOCH-30B series focusing units. |

|

| Maximum energy sharing | Up to 2 deliveries of laser output, including powersharing,are available.(Option) | |

| No. of schedules | 256 | |

| Measurement function | Laser energy (J), Average power (W) | |

| Control Panel | Counter | Displays the total number of outputs (9 digits) |

| Displays the number of acceptable outputs (9 digits) | ||

| Displays the total LD ON time (7 digits) | ||

| Displays the laser output time (7 digits) | ||

| Power requirements | Without cooler | Single-phase, 200 V to 240 V AC (+6% /-10%) 50/60Hz |

| With cooler (option) | Single-phase, 180 V to 220 V AC When the input power supply exceeds 220 V in the model with cooler, use an insulation transformer to keep the voltage within specifications. | |

| Power consumption | Without cooler | Maximum:0.7kW (Standby:0.2kW) |

| With cooler (option) | Maximum:1.1kW (Standby:0.5kW) | |

| Max. apparent power | Without cooler | 800VA |

| With cooler (option) | 1100VA | |

| External datacom | RS-485 | |

| Heat exchange method | Fully air cooled | |

| Dimensions | Without cooler | 400(W)×900(D)×696(H)mm |

| With cooler (option) | 400(W)×971(D)×696(H)mm | |

| Weight | Without cooler | 100Kg |

| With cooler (option) | 120Kg | |

[ Notice ]

This product is subject to Japanese Export Control Law. Depending on its destination, prior assessment and authorization may be required. When exporting from country of initial purchase destination, please be sure to follow that country's export regulations as it may require an export permit beforehand.

Details would like to ask you to inquire to business about it.

Applications

Plastic welding, soldering, etc.

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support