1kW ML-6810C

High power CW laser implements smooth surface of welding!

About 35% lower consumption compaered with previous model

Available for Active Heat Control™

Plaese click here to get the manual

About 35% lower consumption during the operation.

High power CW laser implements smooth surface of welding.

Available for Active Heat Control with dedicated focusing head. It enables to control the heat in processing area precisely.

Suitable for processing in automotive parts and machine parts that need high quality and high precise welding.

Standard Features

Features

-

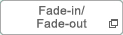

- It's the new function to controll laser output automatically based on the heat of proccessing area.

- It enables to controll laser output to get the heat that is already set up, by doing feedback to laser welder through the dedicated focusing unit.

- It enables to controll laser power based on the heat of the workpiece, different from previous function *1 that contrll laser power based on the osillator power.

- The new fuction is suitable for the processing that the heat controll is important as welding or hardening. Dedicated focusing unit is option and the welder is also dedicated specification.

*1 Real Time Power Feedback

-

Heat conducted welding: Surface

Heat conducted welding: Cross section

-

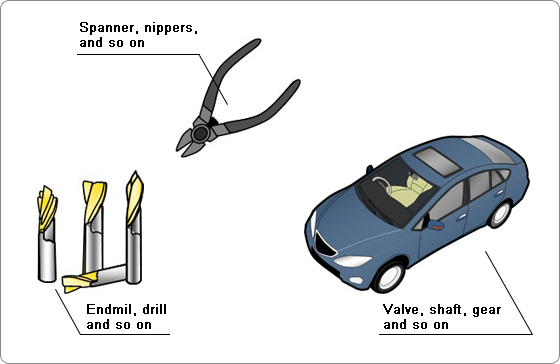

- The product is suitable for many kinds of items and applications due to the features as Acive Heat Control, reflection resistant structure, and high aspect ratio.

- It's recommended to use not only spot&seam welding of iron alloy but also high reflection materials as copper and aluminum.

- Stable heat staking are possible due to Active Heat Control function in automotive industries. Also the new laser welder is able to weld electronic parts in smart phone and electronical components, sensors, and engine parsts in automotive.

- ■ Active Heat Control

- ■ High aspect ratio

-

- The machine design including oscillator is optimized and brightness is improved, compared with previous model.

- Much small and deep welding is possible due to the high aspect ratio.

- ■ Reflection resistant structure

-

- The machine is suitable for welding of high reflection materials as aluminum or copper *2, and supress breakdown *1 coming from high reflection. It enables to avoid the oscillator trouble due to the reflection detecting sensor in the machine.

- ■ Scanning system

-

- Employing the Galvo, implements high speed and high efficiency processing.

- Enables to show its superior brightness according to dedicated optical component.

- ■ Items/applications

- ■ Controlling function

-

- Enables to set up various wave, according to the function.

- Implements various way from high speed precise welding to cutting, according to modulation function. (frequency and waveform)

- ■ Saving energy and space

-

- Reduces energy consumption compared with previous machine, according to design optimization. Ensures wider space to set up machines, according to light and compact design.

- ■ Useful user interface

-

- Large LCD touchscreen allows to input setteings easily. Available for Japanese and English. Enables to use an extension calble.

- ■ Laser power management

-

- Managing laser power in focal point with power meter (opotion), contributes to improvement of product quality.

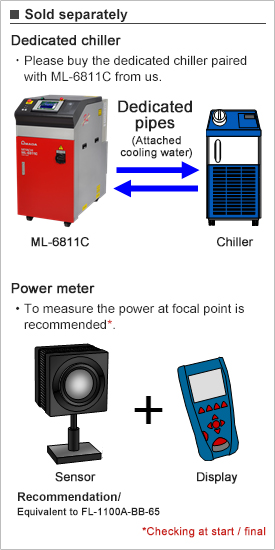

- ■ Dedicated chiller

-

- The pairing with a dedicated chiller is needed to show its maximum ability.

- Please use chiller that our company provides.

- The chiller is delivered with it's water piping, thus a customer doesn't need to prepare it.

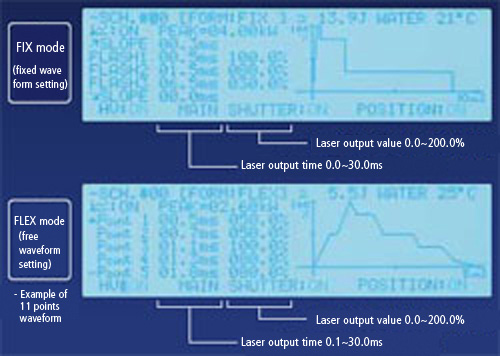

Waveform control

3Equipped with a "fixed mode" that features three-level waveforms, and a "flex mode" to provide more complex waveforms.

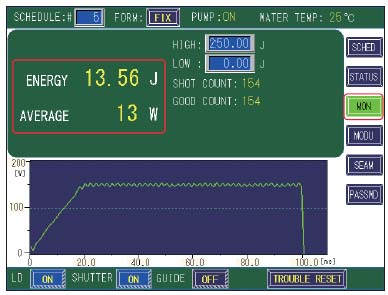

Power monitor

aser energy (J) and average power (W) are monitored to detect abnormalities.

Color LCD touch panel

The touch panel can be detached from the main unit and operated by hand.

External communications

Configuration of parameters and monitoring of performance can be carried out from a separate location.

- Type: RS-485 compliant, asynchronous, full duplex

- Data speed: 9600, 19200, 38400 bps

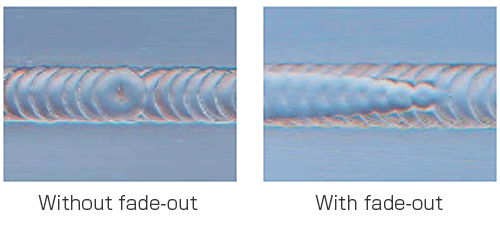

Fade-in/Fade-out

This feature avoids marks at the end of seam welding and provides a beautiful finish even for overlapping circumference seam welding sections.

Specifications

| Model | ML-6810C | |

| Maximum power | 1000W | |

| Mode | Multi mode | |

| Pulse width | REPEAT | Standard:0.1~500.0ms (0.1ms step) |

| Setting switching:0.05~500.00ms(0.05ms steps) | ||

| CW | Standard:0.1~1000.0s (0.1s step) | |

| Setting swichging:0.001~10.000s (0.001s step), 0.01~100.00s (0.01s step), 1~10000s(1s step) |

||

| Repeated number of pulse / modulation | 1~1000pps | |

| Modulation function | 1~5000Hz (rectangular wave, triangular wave, sinusoidal wave) | |

| Oscillation wavelength | Fundamental wavelength | |

| Positioning guide beam | Builtin visible larser (red) | |

| Output stability | ±2%less (Ambient temperature change+/-5℃ in the range), (Water temperature:21to25℃), (Cooling water flow rate 16 to 20 L/min), (Irradiation time 8 hrs in the range) |

|

| Fiber optic delivery | Single fiber delivery / 2 timesharing | |

| Number of schedule | 256 | |

| Measurement function | Laser energy (J), Average power (W) | |

| Counter | Displays the total number of outputs (9 digits), Displays the total number of acceptable outputs (9 digits) Displays the total LD ON time (7 digits), Displays the laser output time (7 digits) |

|

| Length of the laser controller cable | 1m (standard) *Extension is opition | |

| Laser controller and language | Touch panel, Removal (Japanese and English are available) | |

| Power supply / Beaker rated current | 3-phase, 200-240V AC 50/60Hz / 40A | |

| Power consumption | Maximum:4.0kW / Standby 1.0kW less | |

| Cooling method | Water cooling (21 to 25℃) | |

| Ambient temperature / Ambient humidity | 5 to 40℃ / 20 to 85%RH (non-condensing) | |

| Dimension | 556(W) X 1,073(D) X 1,153(H)mm | |

| Weight | 250kg | |

| Dedicated chiller | Power requirement : Single phase 200 to 230V ±10% Frequency : 50/60Hz Breaker : 20A |

|

| Dimension: Approx. 377(W) 900(D) 976(H)mm Caution : Pairing with our laser welder in our company is needed. |

||

*Specifications subject to change without notice.

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support