SSR-5/SSR-6

Rotary Surface Grinder

Rotary surface grinder with three times higher productivity than reciprocation type

The high accuracy ram design and servo-motor-driven axes deliver high accuracy grinding and lower environmental impacts. This Series guarantees stable grinding through constant grind control.

Features

- ■ Features(1) : Three times higher productivity than reciprocation type

-

- SSR-5 can yield three times higher productivity than other horizontal-axis table surface grinders having working area (grinding area) equivalent to SSR-5, in terms of time per grind (end of grinding of all work area).

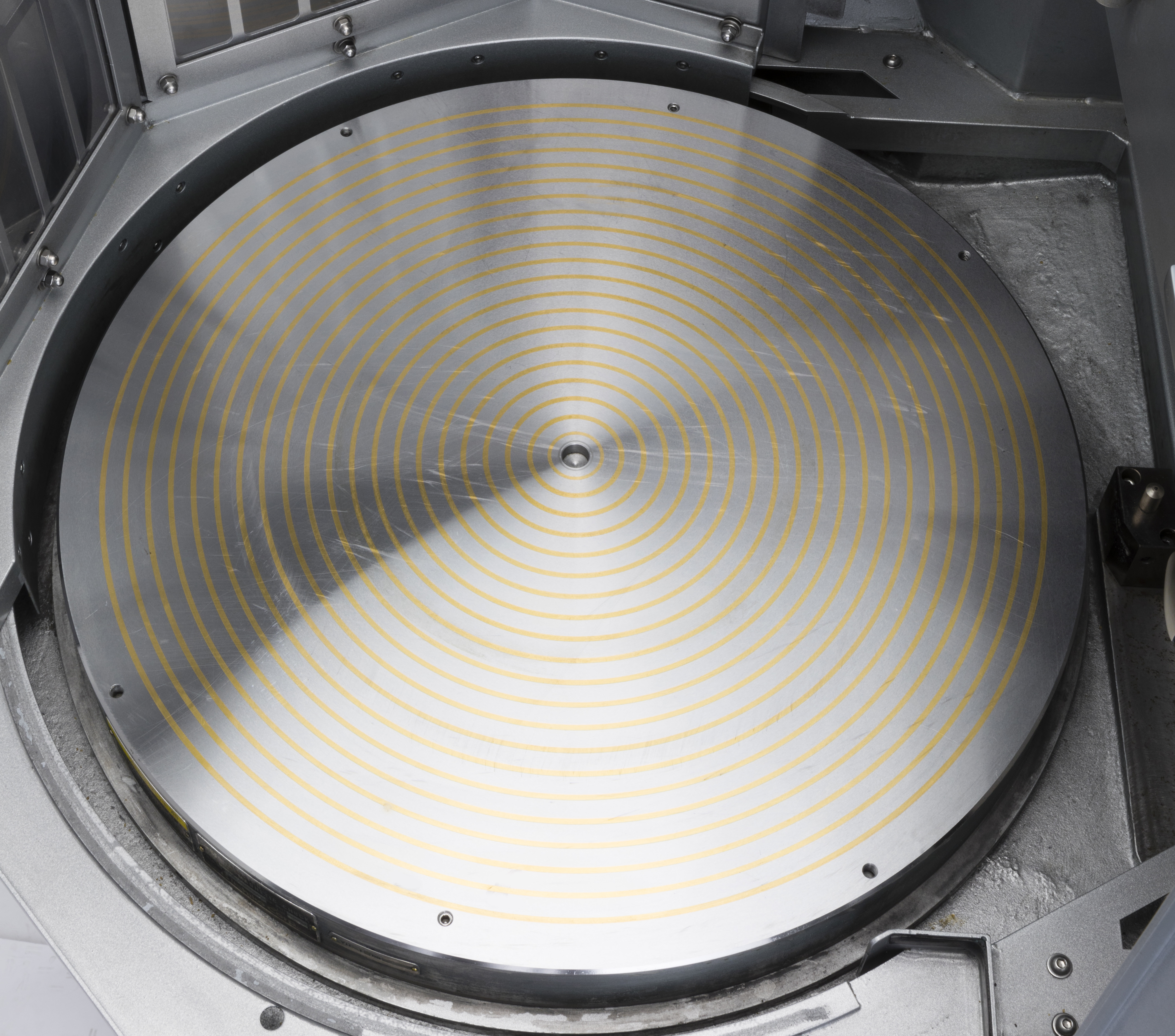

φ500/600 Chuck Table

Processing scene

- SSR-5 can yield three times higher productivity than other horizontal-axis table surface grinders having working area (grinding area) equivalent to SSR-5, in terms of time per grind (end of grinding of all work area).

- ■ Features(2) : Environment-friendly, non-hydraulic ECO machine

-

- Conventional hydraulic mechanism is no longer used. Environmental-friendliness and non-hydraulic NC control can significantly reduce thermal displacement and increase accuracy.

- ■ Features(3) : NC control on all axes

-

- Our original software is installed exclusively for rotary surface grinders.Compatible with Automatic table dressing.

Specifications

|

Model |

SSR-5 |

SSR-6 |

|---|---|---|

|

NC control axis |

Single 2-axis + 1 axis |

|

|

Chuck size (OD) (mm) |

φ508 |

φ600 |

|

Travels (ram/table) (mm) |

335/185 |

337/185 |

|

Wheel spindle motor (kW) |

7.5/11 |

|

|

Wheel spindle grinding wheel size (OD x width x bore) (mm) |

φ355 x 38 x φ127 |

|

Selection Specifications

- Metal Spindle and Ram Sliding Surface Specifications

- Hydrodynamic metal spindle

- High rigidity can be obtained by using a Mackensen type hydrodynamic metal bearing. It realizes highly efficient and high-quality grinding of hard and tough materials.

- A spindle cooling function is provided as standard equipment to suppress changes in accuracy due to heat generation. Quill type spindle improves maintainability.

- V-flat sliding surface

- The overhangless structure prevents the ram from exceeding the bed guide surface, improving the stability of straightness accuracy. The straightness accuracy of less than 3μm is possible.

- The ram guide surface is finished with a chisel to suppress thermal displacement and maintain stable parallelism for a long period of time.

Specifications, appearance and equipment are subject to change without notice by reason of improvement.

This products is for Japan domestic market.

Contact Us

Contact for repair/recovery of AMADA MACHINERY products and our corporate activities.

Contact Us