AMADA MACHINERY

Structural Steel Machines

Combination Machines

Punching & Shearing Machine

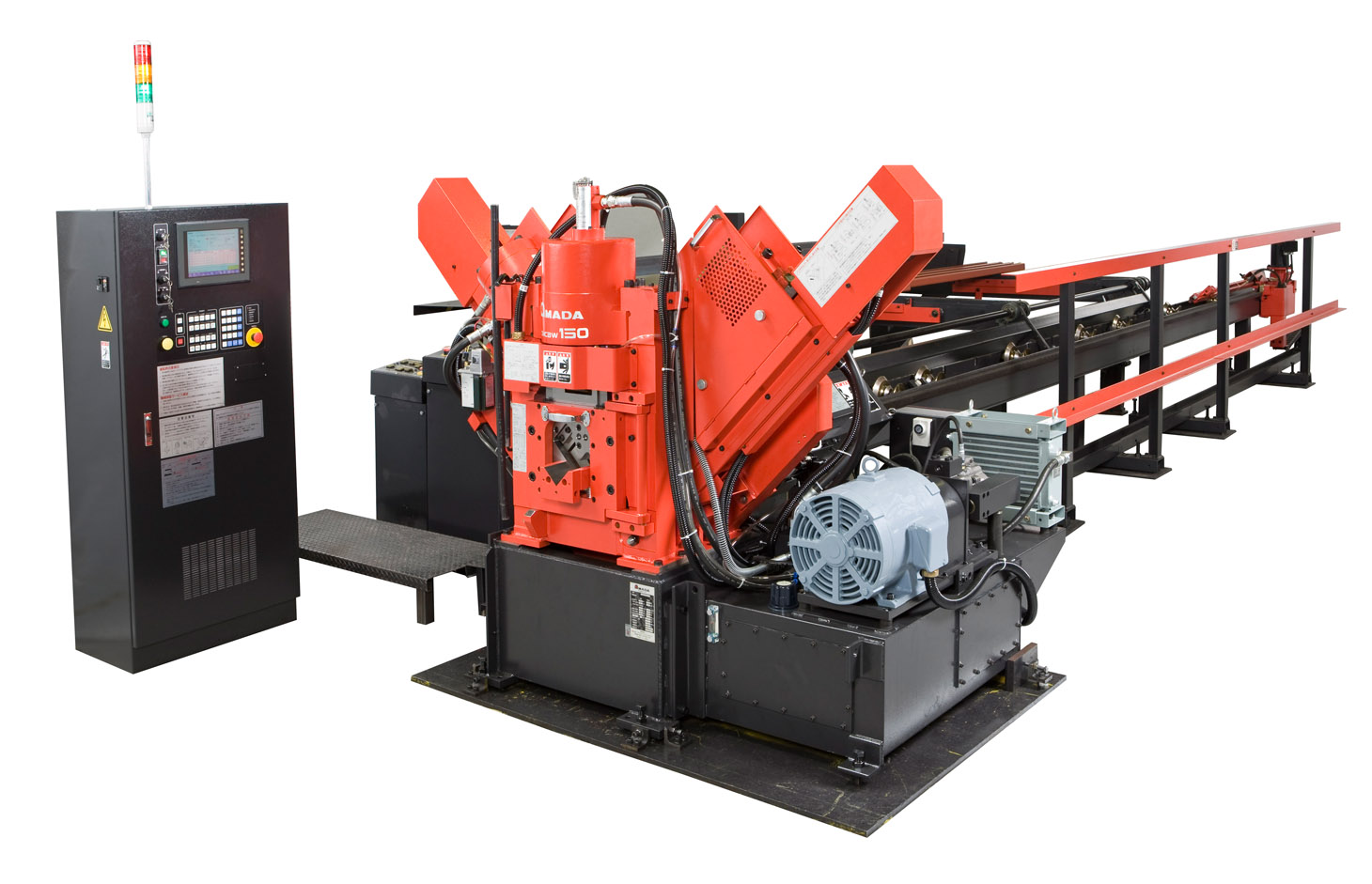

CNCBW-150

Punching and Shearing Combination Machine for Small Structural Steel

This multi-processing machine is designed to punch and shear steel bars such as angle steel and channel steel.

Features

- ■ Features(1) : Higher yield rate

- Minimum remnant length of 90 mm (0-mm remnant at the end of material can be achieved depending on interfacial combination)

- ■ Features(2) : Processing capability to different diameters

- To process one material to make holes of different diameters, the machine pauses to let the clamper automatically lift. After changeover of a punch and a die, the clamper goes down to restart processing.

- ■ Features(3) : Simple operation

- Larger input capacity is available than conventional machines.

- The machine allows for easy changeover of a punch die and a cutting die.

- More than one gauge line can be preset by CNC for automatic positioning.

- ■ Features(4) : Automatic operation mode

- Besides programming of interfacial conditions and setting of dies, all you have to do is just pressing the start button.

- Installation of the flat loader (optional) and an unloader allows for automatic scheduled operation.

- The ink jet marker (optional) automatically marks a material number and a scribe line.

Movies

Material : Box channel steel / 100 x 50 x 20/2.3 mm

Specifications

| Model | CNCBW-150 | |||

| Processing performance (kN) | Cut | 600 x 1 | ||

| Punch | 400 x 2 | |||

| Processing capacity (mm) | Punch hole (φ x thickness) (mm) | φ6 x 3 - φ25 x 12 | ||

| Single cut Cross-sectional area of workpiece Max 15 cm² |

Standard | Angle | 40 x 40 x 3 - 100 x 100 x 7 | |

| Special | Flat bar | 38 x 3 - 100 x 12 | ||

| Channel | 75 x 40 x 5 x 7 - 100 x 50 x 5 x 7.5 | |||

| C channel | 60 x 30 x 10 x 1.6 - 150 x 75 x 25 x 3.2 | |||

| 120 x 60 x 25 and 70 x 40 x 25 are not machinable. |

||||

| Light-weight channel | 50 x 25 x 10 x 2.3 - 150 x 75 x 4.5 | |||

| Double cut | Special | Angle | 40 x 40 x 3 - 150 x 150 x 12 | |

| Flat bar | 38 x 3 - 150 x 12 | |||

| Unequal-sided angle | Longer side equal to or more than 40 and not exceeding 150, thickness of 12 or less |

|||

| Length of product to be processed (mm) | 30 - 12000 | |||

| Material length that can be processed in automatic operation mode (mm) | 1000 - 12000 | |||

| Minimum remnant length (cutting at the end of material) (mm) | 90 | |||

| Motors (kW) | Hydraulic pump | 11 | ||

| Material feed | 0.75 | |||

| Gauge line | 0.2 x 2 | |||

| Power requirement (kVA) | 23 (or 26 with flat loading) | |||

| Machine dimensions (W x L x H) (mm) | 2212 x 2400 x 1648 (not including carriage) |

|||

| Mass of machine (kg) | 4500 (not including flat loading) | |||

Options

- Ink jet marker

- White paint marker

- Flat loader

- Unloader

Service products

- BG-Win (programming software)

These specifications and machinery and equipment appearance are subject to change without notice for reason of improvement.

This products is for Japan domestic market.

Contact Us

Contact for repair/recovery of AMADA MACHINERY products and our corporate activities.

Contact Us