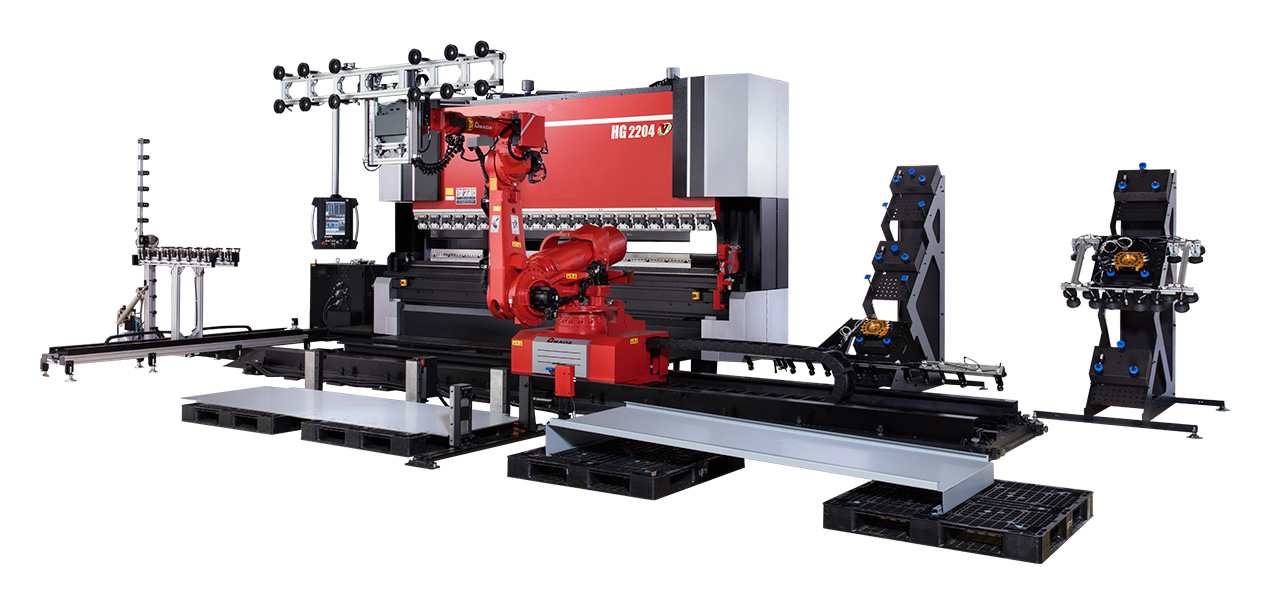

HG-2204Rh

Bending robot system for large and heavy workpieces

Simple operation, and secure, safe and stable bending with a single robot.

Fully automated bending system for large and heavy workpieces

The HG-2204Rh has adopted the high-end press brake HG-2204, equipped with a new hybrid drive system and capable of step bend layout.

Material loading, material handling during bending, and part unloading are all performed by a single 7-axis articulated robot capable of various motions. The HG-2204Rh system can bend large parts and heavy parts without setups and can run for long hours.

Features

- ■ Features(1) : Simple operation with a single robot

- A 7-axis articulated robot (six axes of motion plus one travel axis) is adopted for loading, unloading, positioning and bending workpieces to expand the bending range.

- ■ Features(2) : Expansion of bending range

- The gripper is automatically changed to suit the parts to be bent.

- An automatic gripper changer (AGC) that can store up to six types of grippers is installed as standard.

- ■ Features(3) : Angle sensor

- The angle sensor Bi-S is installed to support angle correction during robotic bending.

Movies

HG-2204Rh

Production Samples

Specifications

|

Capacity |

Maximum workpiece size |

Minimum workpiece size |

Payload |

|

|---|---|---|---|---|

|

HG-2204Rh |

2200 |

1500×4000 |

100×1000 |

165 (with gripper) |

*This product is for the Japanese market.

Contact Us

Contact for repair/recovery of AMADA products and our corporate activities.

Contact Us