WELD CHECKER® (Desk-Top Type) MM-400B

Visible, Judge and control of welding parameter.

Long time measuring is available!

Features

- ■ 【MM-400B】

-

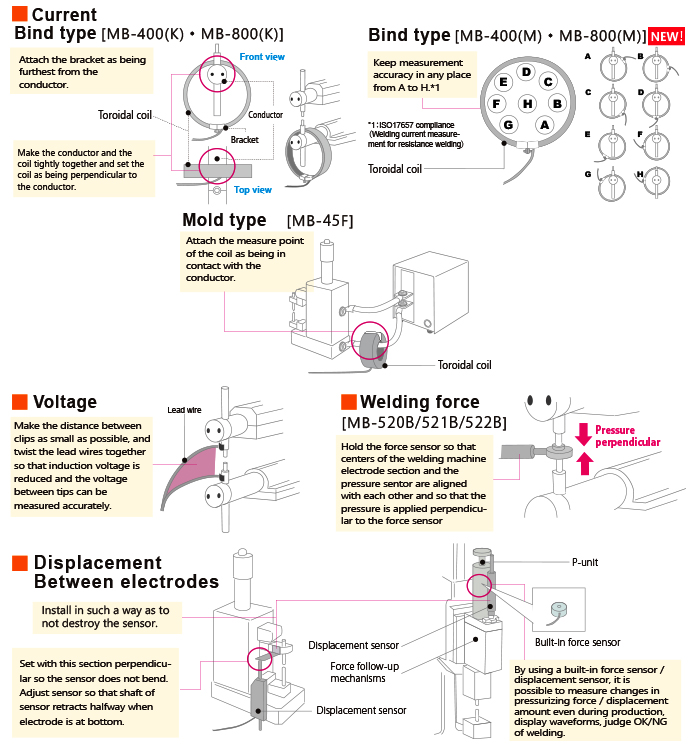

Measures current, voltage, welding time, weld force and displacement!

- Supports a wide range of welding machines

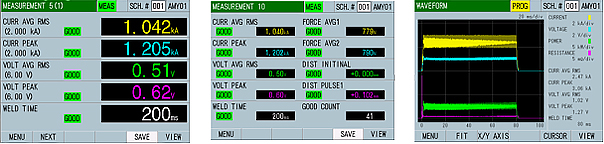

The instrument supports single-phase AC, DC inverter, AC inverter, transistor, and capacitive discharge welding machines. - Various measurement functions

Easy to use with a touch panel.Display waveforme up to 4 items. Display and judge the parameters of the welding quality determinant up to 10 items. -

Display screen

- ISO17657-compliant measurement

In addition to the arithmetic mean RMS which is a conventional calculation system, the RMS in a whole current flow time which is the ISO17657 (Resistance welding -- Welding current measurement for resistance welding -- )-compliant calculation system can be selected. For the ISO17657-compliant measurement, the dedicated ISO-compliant toroidal coil is required. - Supports multiple languages

Languages available are Japanese, English, Chinese, Korean, German, French, and Spanish. - ■ New Features

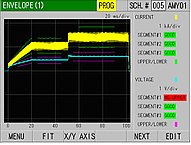

- Envelope function

Making the OK/NG judgment by comparing a waveform within an allowable range and a monitored waveform, enables management with waveforms in addition to conventional measured values.

(Up to 3 points 2 waveforms) -

- Measuring displacement Before-Welding

Measures Before-welding workpiece thickness, judge OK/NG of thickness. - ■ Memory / Comumication / Printing

- Memory

Measured values and waveforms can be saved in a built-in flash memory device/external USB. - Comunication

RS-232C, RS-485, Ethernet Simplex and duplex communication possible.(option) - Printing

Measured data and wavefome can be printing. - ■ Judgment / Control function

-

- By using a built-in force sensor / displacement sensor, it is possible to measure changes in pressurizing force / displacement amount even during production, display waveforms, judge OK/NG of welding.

- Weld stop function shifted from 2 outputs to 3 outputs. Fine control of changes in displacement and applied pressure during welding.

- With external input function, voltage input (± 10 V) current input (4 to 20 mA) from other sensors such as temperature sensor can be measured, waveform display, and OK/NG judge possible.

- ■ Long time measurement:MM-400B-02-05

-

- Current and voltage are maesured in a maximum of 10 sec in AC/DC welding.

Measurement method

Specifications

| MODEL | MM-400B-00-00/-00-01※1 | MM-400B-02-05 | |||||

| Measurement specification |

Current | Range | 1×Sensitivity toroidal coil:0.100~2.000kA/0.30~6.00kA/1.00~20.00kA/3.0~60.0kA/10.0~200.0kA 10×Sensitivity toroidal coil:0.010~0.200kA/0.03~0.60kA/0.100~2.000kA/0.30~6.00kA/01.00~20.00kA Accuracy ±1% of full scale of each range(Excluding sensor's error) |

Current sensor:1.00~20.00kA |

|||

| Item | PEAK/RMS*2/Arithmetic mean RMS | PEAK/Arithmetic mean RMS | |||||

| Voltage | Range | 0.30~6.00V/1.0~20.0V Accuracy ±1% of full scale of each range (Excluding sensor's error) | |||||

| Items | PEAK/RMS*2/Arithmetic mean RMS | PEAK/Arithmetic mean RMS | |||||

| Force*1 | Range |

4.90~98.06N(MA-520B)、49.0~980.6N(MA-521B)、245~4903N(MA-770A※3)、 |

|||||

| Items | Mean RMS/PEAK Before welding/After welding/Constant Accuracy ±3% of full scale (Excluding sensor's error) |

||||||

| Displacement*1 | Range |

When the increment is 1μm:±30.00mm Accuracy ±30.000mm range:±15μm (sensor with 1μm or less resolution) |

|||||

| Items | Before welding/After each welding/Constant | ||||||

| External | Voltage and Current Range | -10 to +10V or 4 to 20mA | |||||

| Range | 5% to 100% of rated setting | ||||||

| Items | Mean RMS/PEAK Before welding/After welding/Constant Accuracy ±3% of full scale (Excluding sensor's error) | ||||||

| Units | V/N/kgf/Ibf/℃/℉/Mpa/bar/psi | ||||||

|

Measurement |

Current Voltage Displacement*1 Power Resistance |

AC | ms-AC:1~5000ms CYC-AC:0.5~250.0CYC(50Hz)、0.5~300.0CYC(60Hz) CYC***Hz-AC:0.5~200.0CYC(M050:50Hz)、0.5~300.0CYC(M063:63Hz)、0.5~2000.0CYC(M500:500Hz) LONG CYC-AC:0.5~500.0CYC(50Hz)、0.5~600.0CYC(60Hz) |

ms-AC:1~10000ms CYC-AC:0.5~500.0CYC(50Hz)、0.5~600.0CYC(60Hz) CYC***Hz-AC:0.5~500.0CYC(M050:50Hz)、0.5~600.0CYC(M063:63Hz)、0.5~3000.0CYC(M500:500Hz) |

|||

| DC | CYC-DC:0.5~100.0CYC(50Hz)、0.5~120.0CYC(60Hz) ms-DC:1~2000ms SHORT ms-DC:0.50~300.00ms(0.05ms increment) |

CYC-DC:0.5~500.0CYC(50Hz)、0.5~600CYC(60Hz) ms-DC:1~10000ms |

|||||

| Force*1,external | 10~10000ms | ||||||

| Conduction angle | Range | 0 to 180 degrees Accuracy:±9 degrees | |||||

| Number of schedule | 127 schedules | ||||||

| Specification | Power supply | Single phase AC100V~240V±10%(50/60Hz) | |||||

| External data output | RS-232C/RS-485/Ethernet (Protocol:TCP/IP) | ||||||

| Language | Japanase/English/German/French/Spanish/Chinise/Korean) | ||||||

| Power consumption | 40W(Max 50W when printer running) | ||||||

| Dimension | 172(W)mm×288(D)mm×266(H)mm | ||||||

| Weight | Approx. 5kg | ||||||

| Toroidal coil | MB-400P*2/MB-800P*2/MB-45G*3 | ||||||

| Shunt resistor*3 | DS 500A/100mV(range between 25A and 500A) DS 1000A/100mV(range between 50A and 1000A) |

ー | |||||

*1: Displacement and force sensors are only available for MM-400B-00-01 and MM-400B-02-05

*2: ISO17657-compliant

*3: Can not be used with MM-400B-02-05

* Force sensors, Displacement sensors, Current/Force sensors, and Toroical coil are all option.

* Specifications are subject to change without nocice.

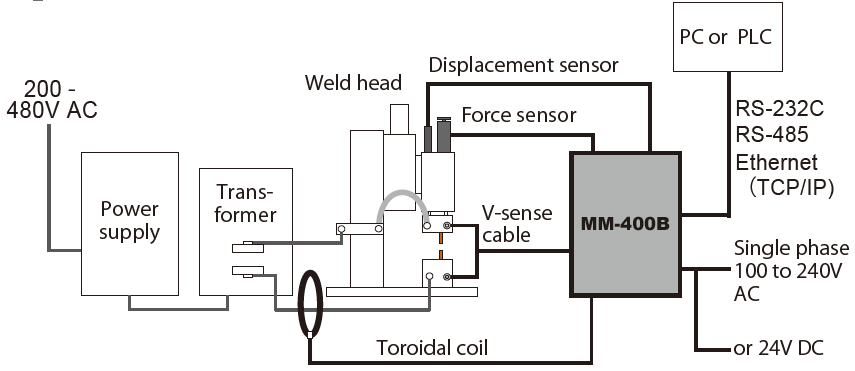

Configuration diagram

Accessories

Customer support

If you have any questions as the products, reparing, and corporate information, plaese contact us.

Customer support